Electronic water pump and vehicle

A technology for electronic water pumps and pump casings, applied in pumps, pump devices, pump components, etc., can solve problems such as poor cooling effect and small flow rate, and achieve the effects of improving reliability, saving installation space, and simplifying product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

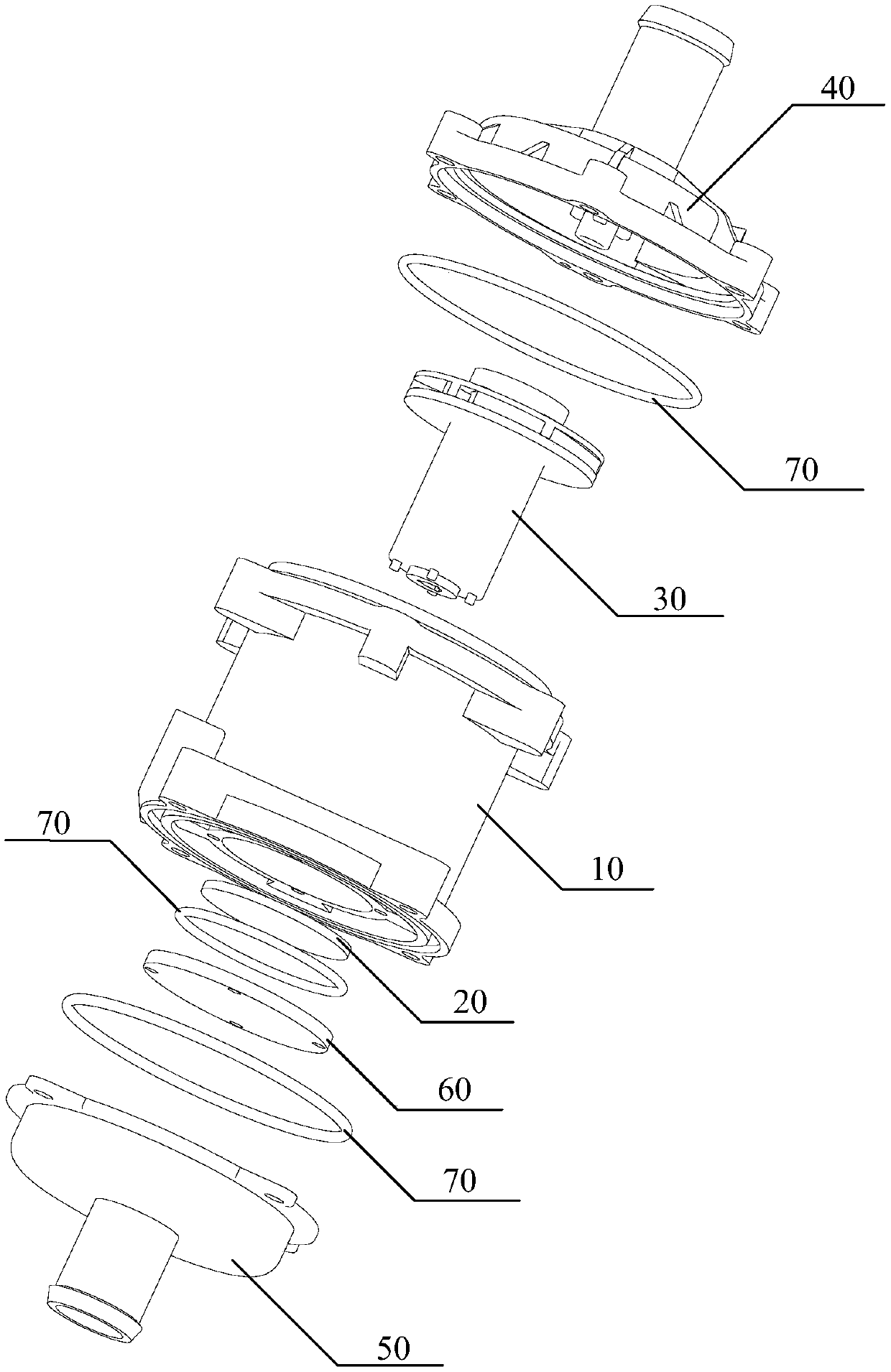

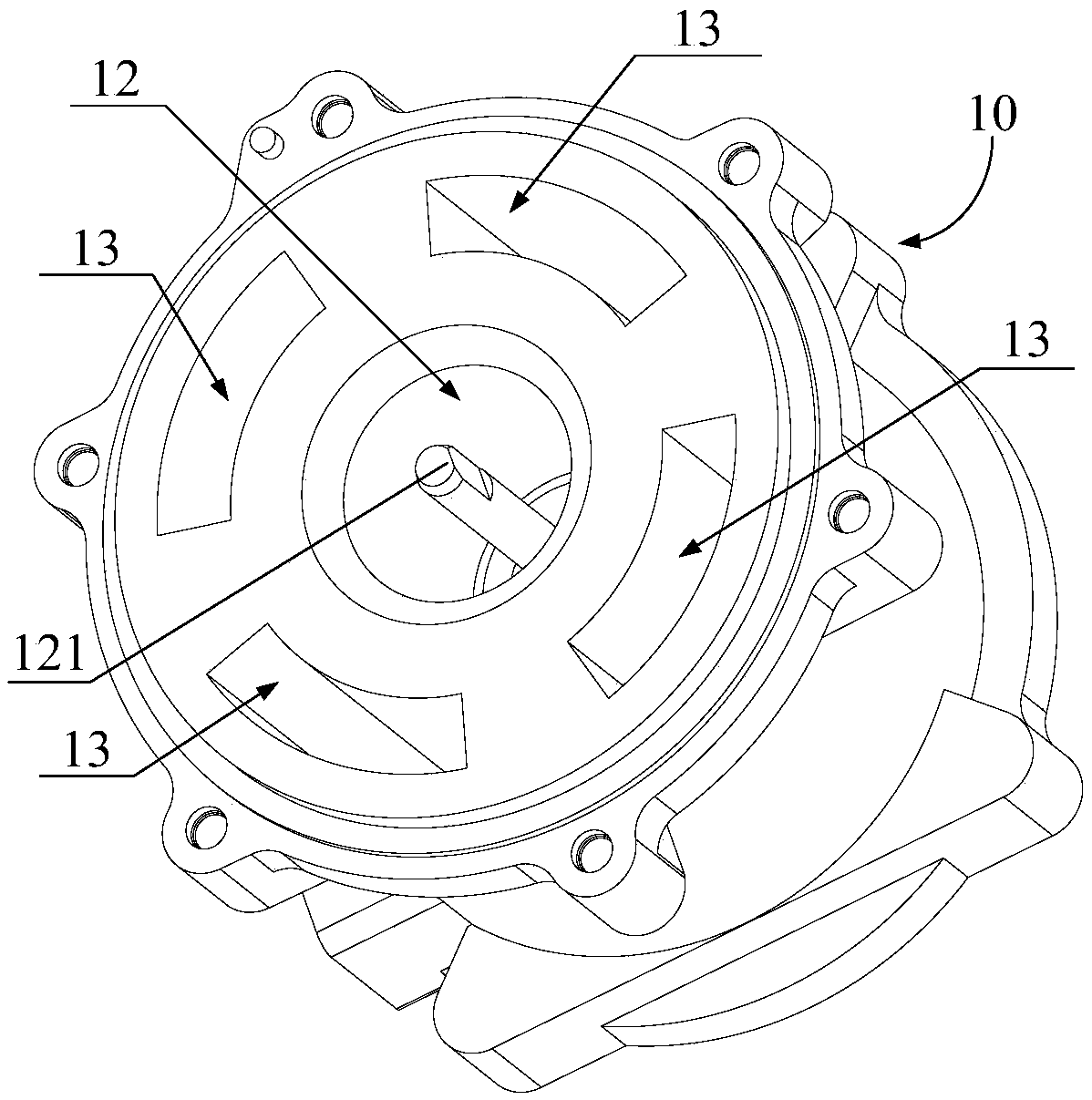

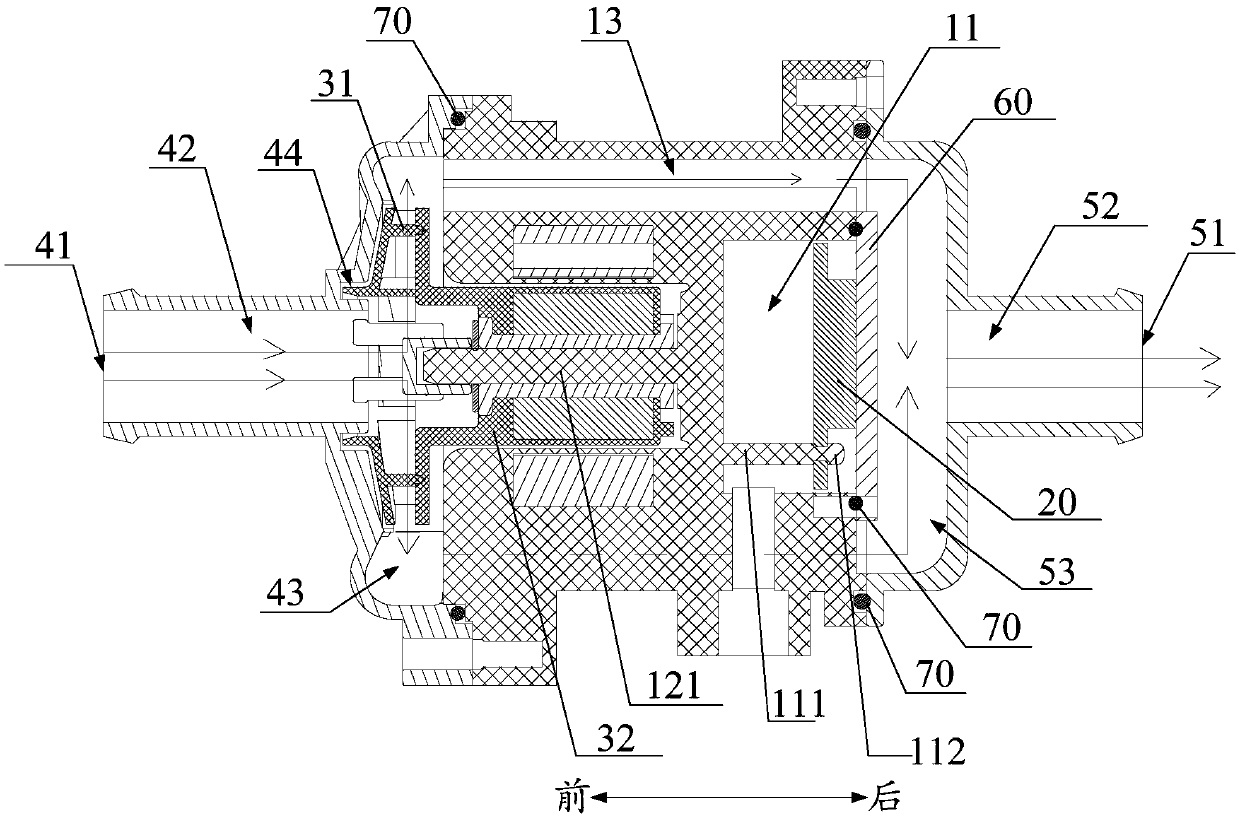

[0077] Such as image 3 As shown, the casing assembly includes a pump casing assembly and a casing stator assembly 10 connected to the pump casing assembly. The pump casing assembly is provided with a water inlet 41 and a water outlet 51. The casing stator assembly 10 defines a first installation cavity 11, At least part of the water circulation channel and the second installation cavity 12; the impeller rotor assembly 30 of the electronic water pump can be rotatably installed in the casing assembly, and at least partly located in the second installation cavity 12, the casing stator assembly 10 includes the impeller rotor assembly 30 Isolated stator assembly.

[0078] Splitting the casing assembly into the pump casing assembly and the casing stator assembly 10 not only simplifies the structure of each part of the casing assembly, facilitates processing and molding, but also facilitates the assembly of components such as the electric control board 20 in the casing assembly; the...

Embodiment 2

[0115] The difference from Embodiment 1 is that: on the basis of Embodiment 1, further, the first installation chamber 11 includes a cavity with one end open and a cover plate 60 adapted to the open end of the cavity, such as figure 1 and image 3 As shown, the cover plate 60 can cover the open end of the cavity to package the electric control board 20 in the first installation cavity 11 .

[0116] The first installation cavity 11 includes a cavity body and a cover plate 60, one end of the cavity body is open, which is convenient for installing the electric control board 20, and the cover plate 60 is adapted to the open end of the cavity body, thereby being able to cover the open end of the cavity body, It is ensured that the electric control board 20 can be packaged in the first installation cavity 11 , so as to prevent the electric control board 20 from directly contacting the coolant, and ensure the reliability of the electric control board 20 . Further, for the solution i...

Embodiment 3

[0128] The difference with the second embodiment is that: on the basis of the second embodiment, further, the electric control board 20 is clamped in the first installation cavity 11, as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com