Transmission electron microscope sample and method for producing same

A technology of electron microscope and manufacturing method, which is applied in the field of transmission electron microscope sample manufacture and transmission electron microscope sample, can solve the problem of indistinguishable silicon dioxide thin film, etc., and achieve the effect of easy measurement, clear interface and clear image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Transmission electron microscope (TEM) sample preparation method of the present invention comprises the following steps:

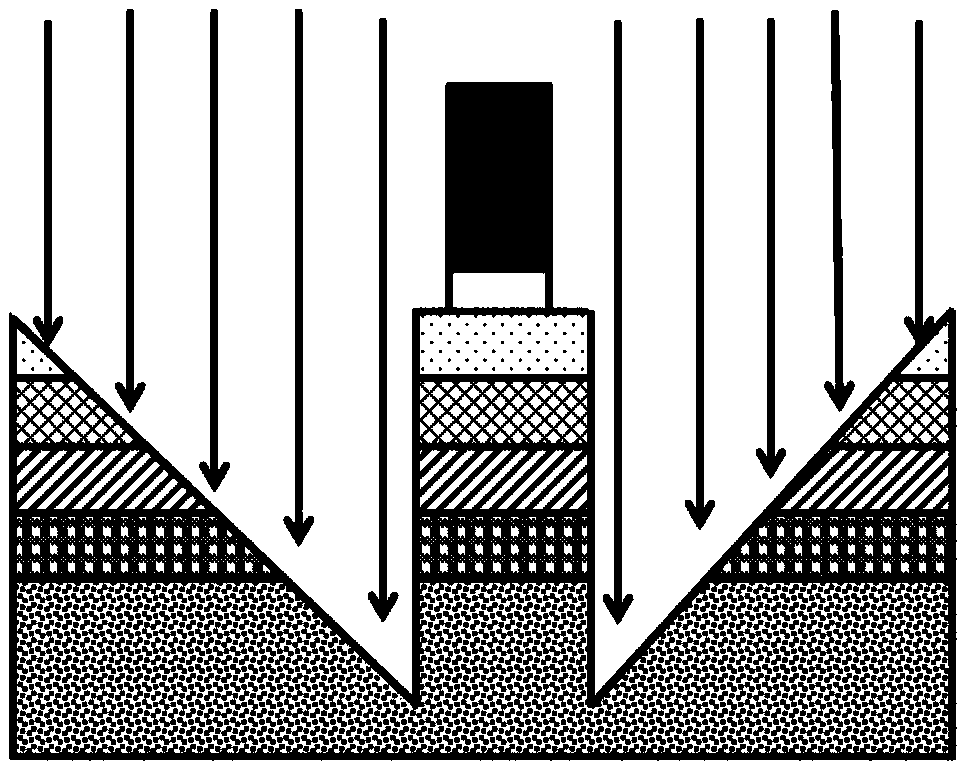

[0038] Step 1, put the sample into FIB (Focused Ion beam, focused ion beam), find the target area, deposit metal protection under E-Beam (electron beam, electron beam), I-Beam (Ion Beam, ion beam) layer. Focused ion beam technology (Focused Ion beam, FIB) is to use the electric lens to focus the ion beam into a very small ion beam bombarding the surface of the material, so as to realize the stripping, deposition, implantation, cutting and modification of the material. With the development of nanotechnology, nanoscale manufacturing industry is developing rapidly, and nanofabrication is the core part of nanomanufacturing industry. The representative method of nanofabrication is focused ion beam. Focused ion beam technology (FIB) uses high-intensity focused ion beams for nano-processing of materials, combined with scanning electron microscopes (SEM) a...

Embodiment 2

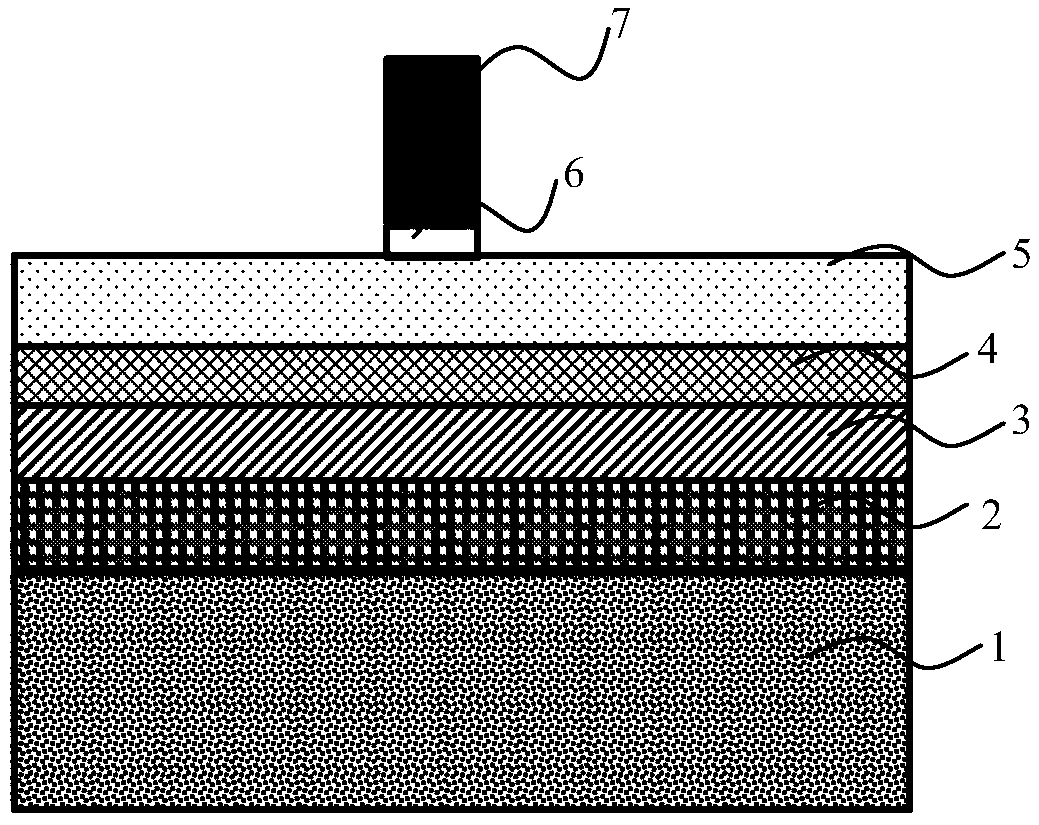

[0053] The invention also discloses a transmission electron microscope sample. The sample includes a silicon substrate, a polysilicon layer 2, a silicon nitride layer 3, a silicon dioxide thin film layer 4 grown based on a high aspect ratio process from bottom to top, and A doped silicate glass layer 5, an electron beam protection layer 6 and an ion beam protection layer 7; the non-doped silicate glass layer has a first thickness 9, and the silicon dioxide film grown based on a high aspect ratio process The layer has a second thickness 10, the silicon substrate, the polysilicon layer and the silicon nitride layer have a third thickness 11, and the values of the first thickness 9, the second thickness 10 and the third thickness 11 are different. The difference range between the first thickness 9 and the second thickness 10 is between 10nm-100nm, and the difference range between the second thickness 10 and the third thickness 11 is also between 10nm-100nm.

[0054] The method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com