Automatic control device for battery cycle test

An automatic control device and battery cycle technology, applied in program control, computer control, general control system, etc., can solve the problems of inconvenient use, bulky test equipment, etc., to avoid accidents and losses, fast installation and maintenance, charging and discharging current The effect of directional protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

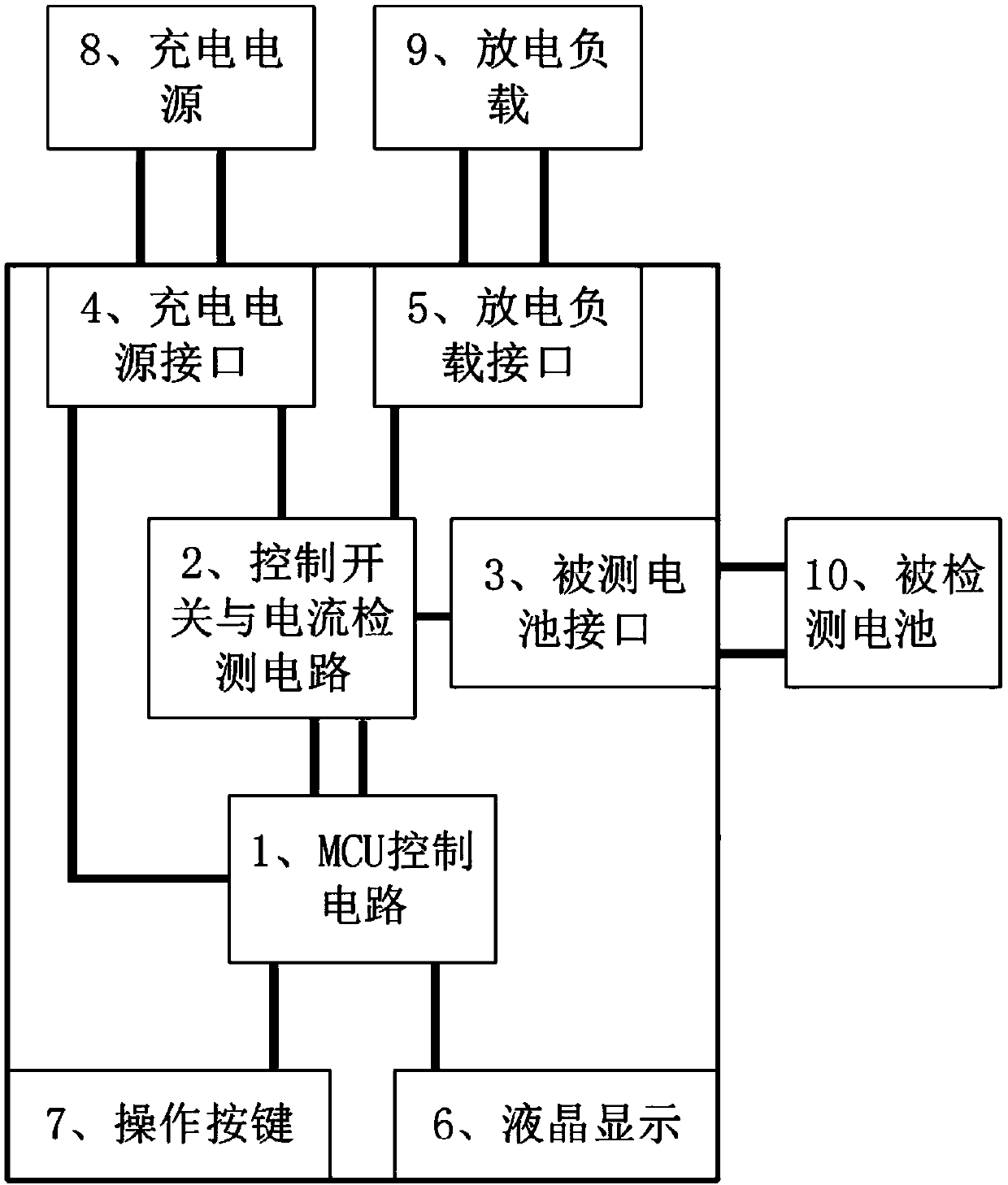

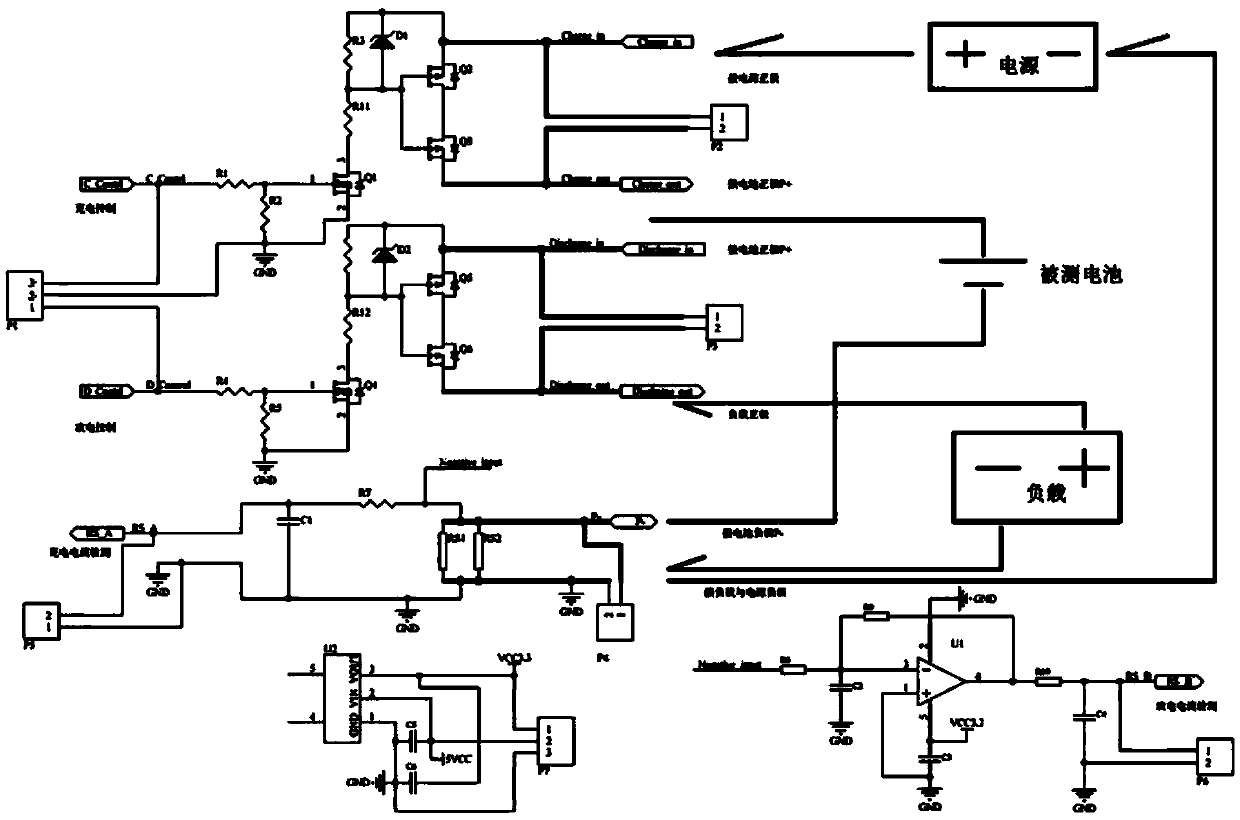

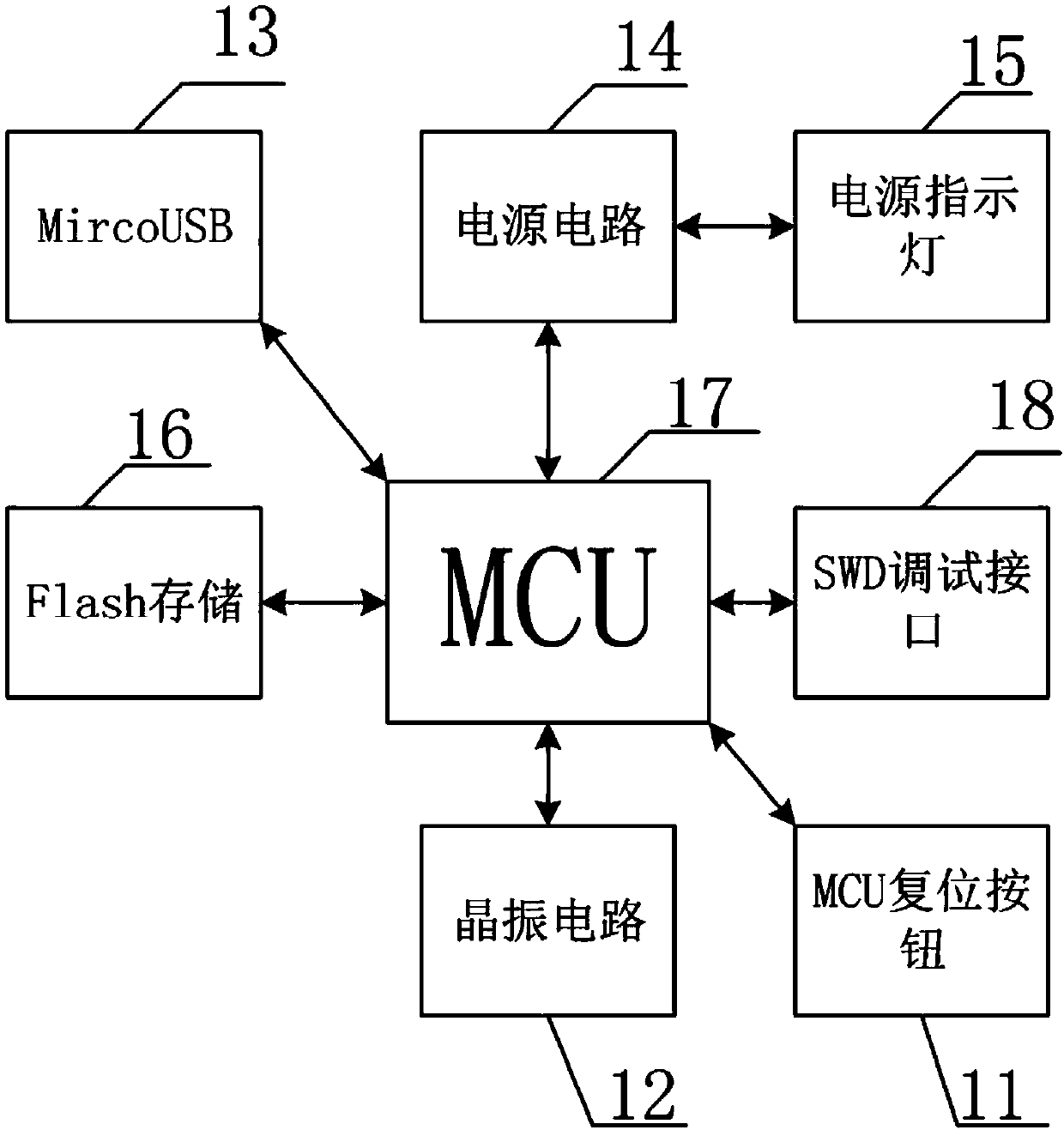

[0030] Example 1, figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of a control switch and a current detection circuit of the present invention; image 3 It is a schematic diagram of the MCU control circuit structure; Figure 4 It is a schematic diagram of the reverse amplifier circuit structure.

[0031] see Figure 1-Figure 4 , the present invention provides an embodiment: an automatic battery cycle test control device, including an MCU control circuit 1, a control switch and a current detection circuit 2, a battery interface under test 3, a charging power interface 4, a discharge load interface 5, and a liquid crystal display 6. Operation button 7, charging power supply 8, discharge load 9 and detected battery 10; the MCU control circuit 1 is connected with the control switch and current detection circuit 2, liquid crystal display 6, operation button 7 and charging power supply interface 4; The control switch an...

Embodiment 2

[0041] Example 2, figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of a control switch and a current detection circuit of the present invention; image 3 It is a schematic diagram of the MCU control circuit structure; Figure 4 It is a schematic diagram of the reverse amplifier circuit structure.

[0042] see Figure 1-Figure 4 , the present invention provides an embodiment: an automatic battery cycle test control device, including an MCU control circuit 1, a control switch and a current detection circuit 2, a battery interface under test 3, a charging power interface 4, a discharge load interface 5, and a liquid crystal display 6. Operation button 7, charging power supply 8, discharge load 9 and detected battery 10; the MCU control circuit 1 is connected with the control switch and current detection circuit 2, liquid crystal display 6, operation button 7 and charging power supply interface 4; The control switch an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com