Steel coil sequence accurate positioning method based on multi-carrier identification technology

An identification technology and precise positioning technology, which is applied in the field of precise positioning of steel coil sequence based on multi-carrier identification technology, which can solve the paralysis of automatic production system, unfavorable tracking and management of steel coil quality, and inability to accurately determine the sequence of labels within the identification range, etc. problems, to achieve the effect of standardization, improving integrity, and reducing coding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention, but it is not used as a basis for limiting the present invention.

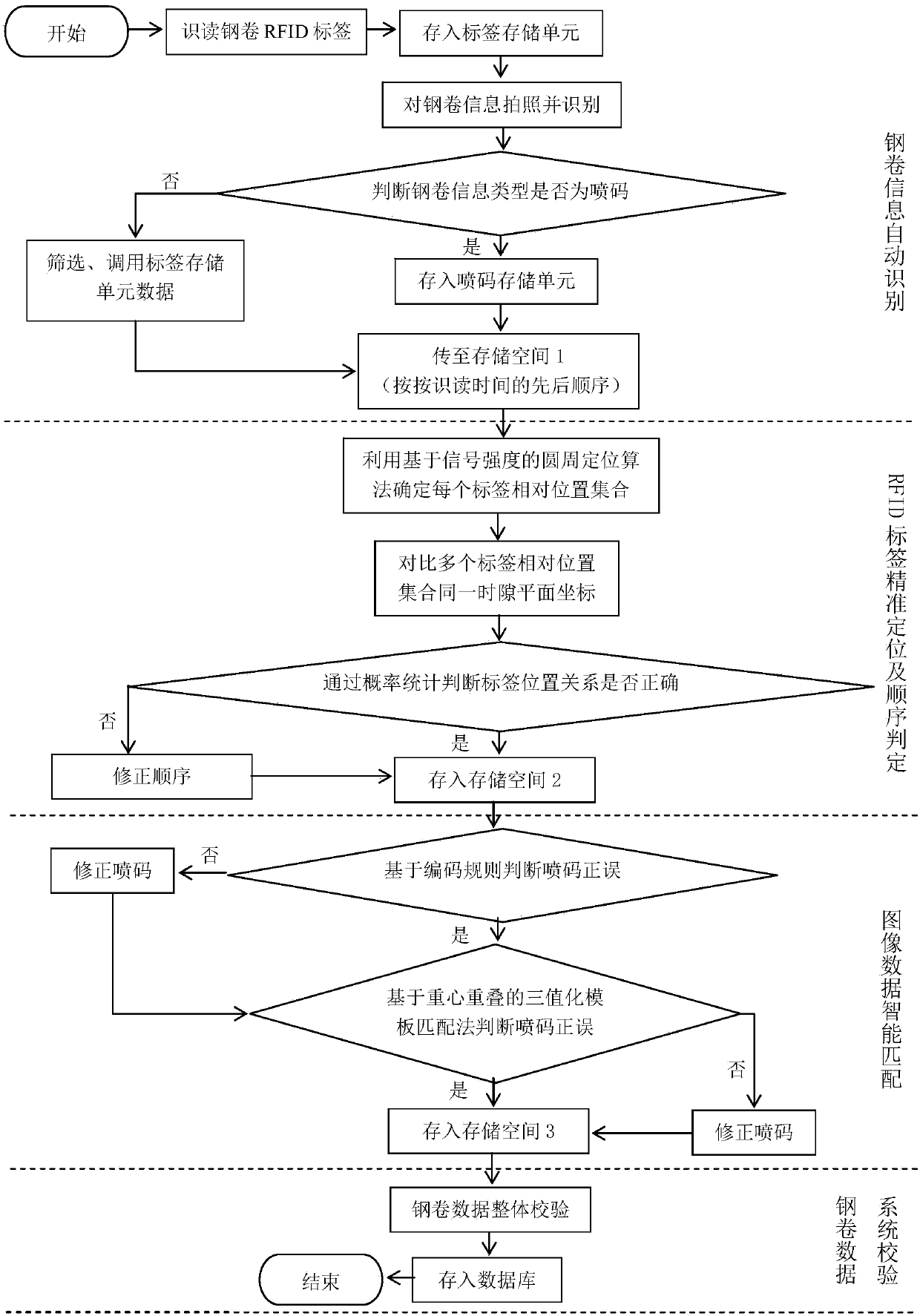

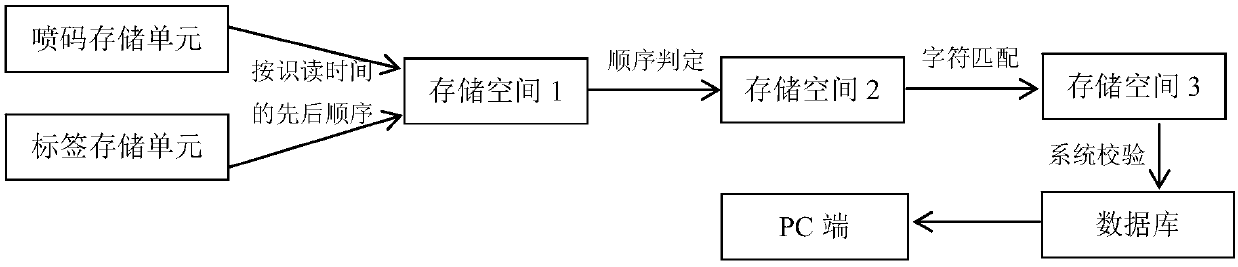

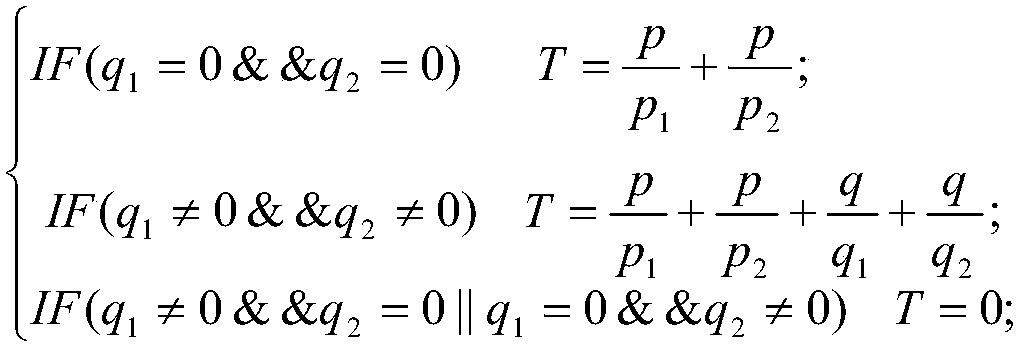

[0016] The logic flow chart of the precise positioning method of steel coil sequence based on multi-carrier identification technology is as follows: figure 1 As shown, the present invention includes four functions: automatic identification of steel coil information, precise positioning and order determination of RFID tags, intelligent matching of image data, and system verification of steel coil data. This method adopts the idea of modular sequential research and development, and achieves the purpose of precise tracking of steel coil information through front-end data collection, accurate judgment of logical algorithm sequence, realization of image data re-matching, and restriction of four-layer conditional judgmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com