Battery heat exchange device, power battery assembly and power automobile

A technology for heat exchange devices and power batteries, applied in electrical components, secondary batteries, circuits, etc., can solve problems such as inconsistent temperature distribution of battery modules, improve temperature consistency, increase heat exchange efficiency, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

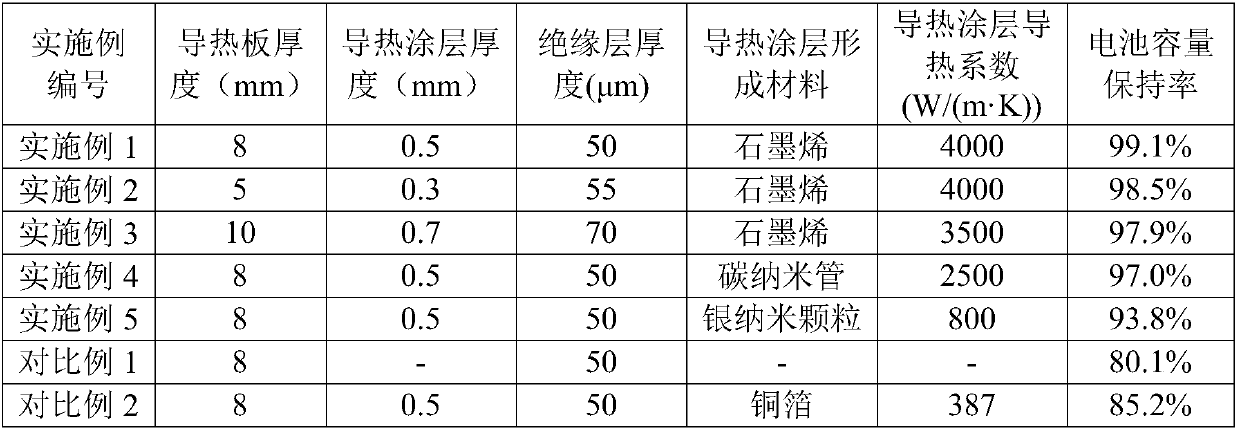

Embodiment 1

[0041] This embodiment is used to illustrate the structural composition and working principle of the battery heat exchange device and the power battery assembly.

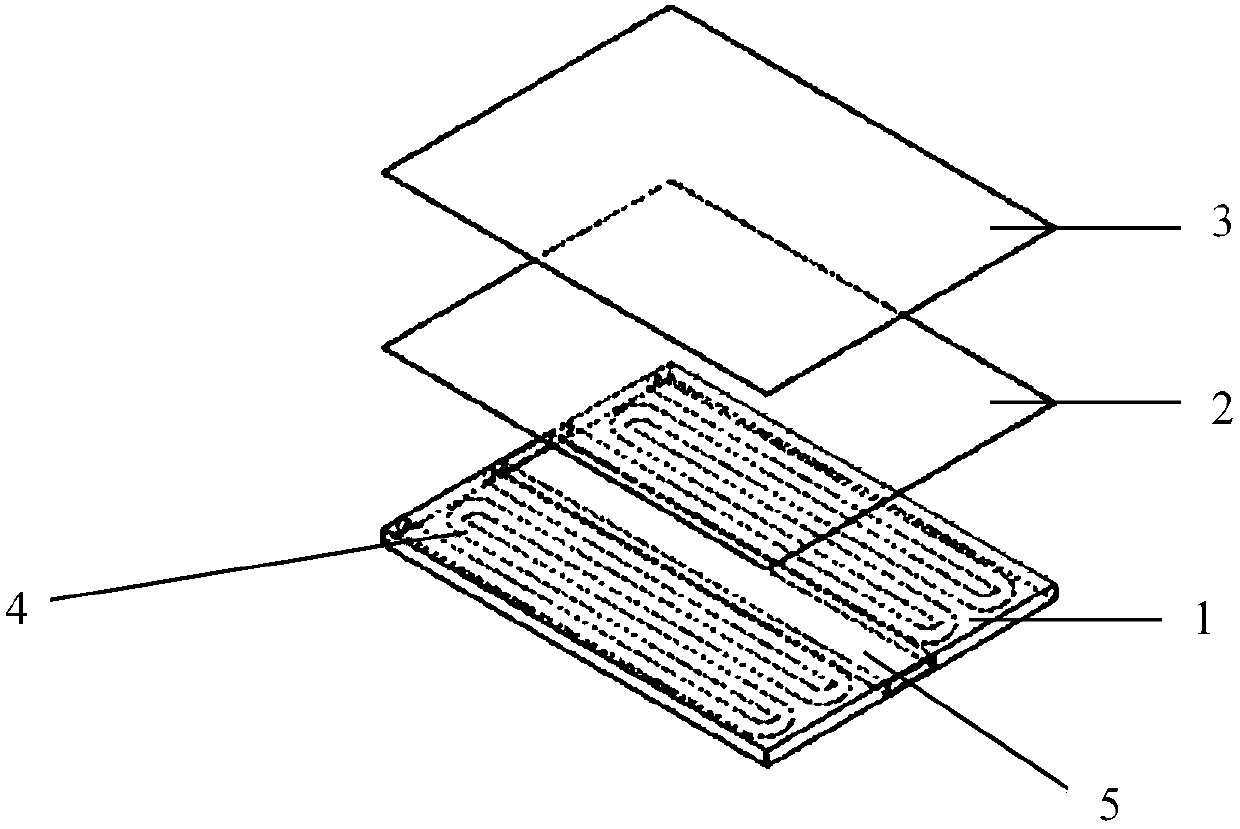

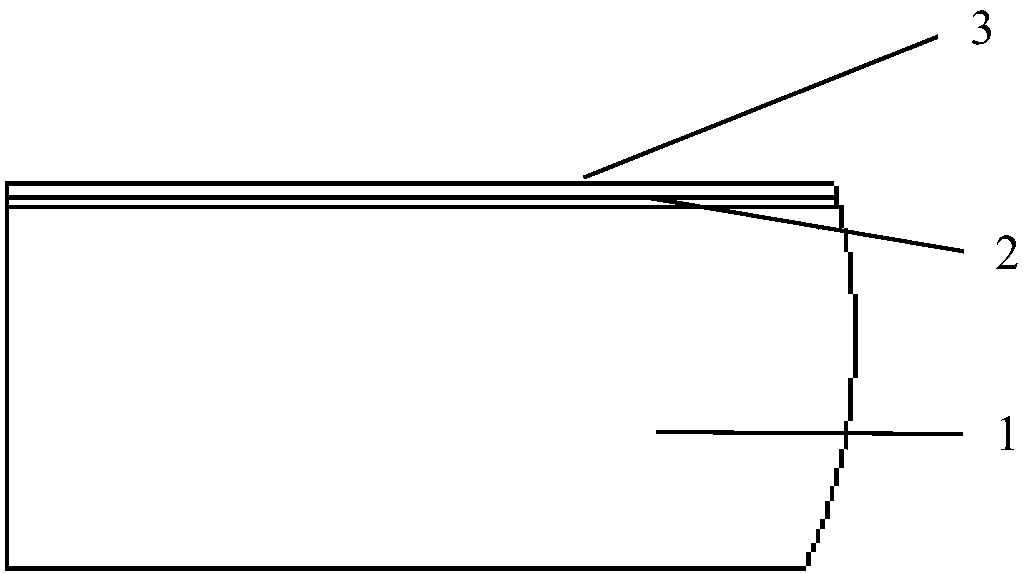

[0042] The schematic diagram of the structure of the battery heat exchange device provided by the present invention is as follows: figure 1 with figure 2 As shown, the battery heat exchange device includes a heat conduction plate 1, a heat conduction coating 2 and an insulating layer 3 arranged in sequence from bottom to top, wherein the thickness of the heat conduction plate 1 is 8mm, and the thickness of the heat conduction coating 2 is The thickness is 0.5 mm, and the thickness of the insulating layer 3 is 50 μm. In the battery heat exchange device, the material of the heat conducting plate 1 is 6063 aluminum alloy, and its thermal conductivity is 202.4W / (m·K); the forming material of the heat conducting coating 2 is graphene, and its thermal conductivity is is 4000W / (m·K); the insulating layer 3 is made of PE...

Embodiment 2

[0046] This embodiment is used to illustrate the structural composition and working principle of the battery heat exchange device and the power battery assembly.

[0047] The schematic diagram of the structure of the battery heat exchange device provided by the present invention is as follows: figure 1 with figure 2 As shown, the battery heat exchange device includes a heat conduction plate 1, a heat conduction coating 2 and an insulating layer 3 arranged in sequence from bottom to top, wherein the thickness of the heat conduction plate 1 is 5 mm, and the thickness of the heat conduction coating 2 is The thickness is 0.3 mm, and the thickness of the insulating layer 3 is 55 μm. In the battery heat exchange device, the material of the heat conducting plate 1 is 6063 aluminum alloy, and its thermal conductivity is 202.2W / (m·K); the forming material of the heat conducting coating 2 is graphene, and its thermal conductivity is is 4000W / (m·K); the insulating layer 3 is made of P...

Embodiment 3

[0051] This embodiment is used to illustrate the structural composition and working principle of the battery heat exchange device and the power battery assembly.

[0052] The schematic diagram of the structure of the battery heat exchange device provided by the present invention is as follows: figure 1 with figure 2 As shown, the battery heat exchange device includes a heat conducting plate 1, a heat conducting coating 2 and an insulating layer 3 arranged in sequence from bottom to top, wherein the thickness of the heat conducting plate 1 is 10mm, and the thickness of the heat conducting coating 2 is The thickness is 0.7 mm, and the thickness of the insulating layer 3 is 70 μm. In the battery heat exchange device, the material of the heat conducting plate 1 is 6063 aluminum alloy, and its thermal conductivity is 202.2W / (m·K); the forming material of the heat conducting coating 2 is graphene, and its thermal conductivity is is 3500W / (m·K); the insulating layer 3 is made of P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com