SDN-based multi-modal data interaction system and method for intelligent production line

A data interaction and multi-modal technology, applied in the direction of digital transmission system, data exchange network, transmission system, etc., can solve the problems that affect the overall compatibility of the system, increase the system maintenance cost, prolong the development cycle, etc., to ensure reliable real-time transmission , Improve network congestion, accurate object-oriented and demand effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

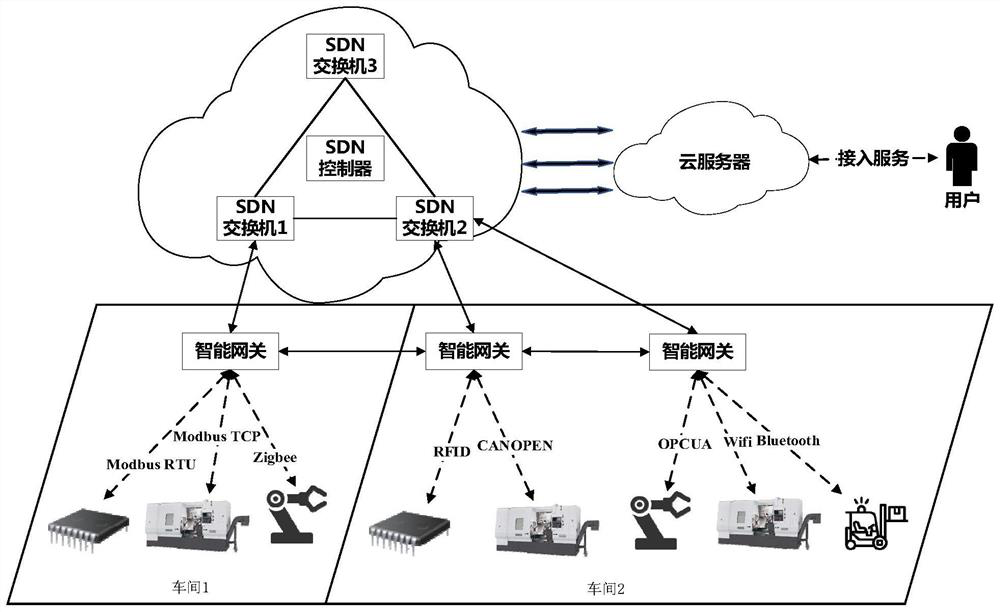

[0034] This embodiment provides an SDN-based multi-modal data interaction system for intelligent production lines. The system includes four layers: equipment layer, conversion layer, network layer, and server layer. The equipment layer includes terminals and data of intelligent production lines. collection node. The terminal equipment mainly involves three aspects: product, processing, and transportation. The product aspect includes raw material addition and finished product packaging; the processing aspect includes processing equipment such as robotic arms and lathes; the transportation includes the movement and status detection of the production line. Due to the different manufacturers of each device, the types of communication protocols used for underlying data transmission are different. At present, there are more: ModbusTCP, ModbusRTU, OPCUA, RFID, Zigbee, Wifi, etc. Firstly, the equipment in the production line is divided according to function and area, and some areas or...

Embodiment 2

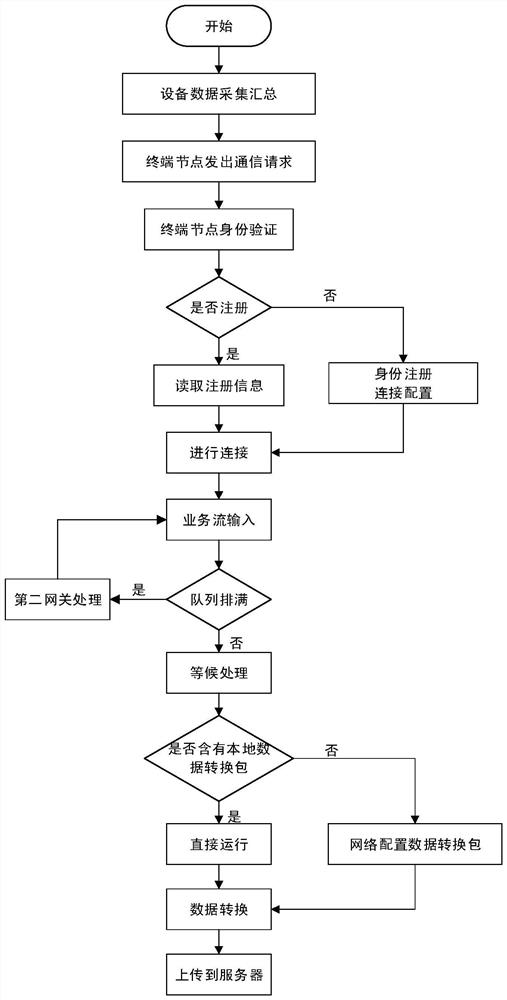

[0040] This embodiment provides an SDN-based multimodal data interaction method for an intelligent production line, the method comprising the following steps:

[0041] The distributed sensor network is used to collect the data of the bottom equipment, the bottom equipment in the intelligent production line is divided according to the function and area, and a data collection node is set up in each sensor local area network to collect and forward the equipment operation information ;

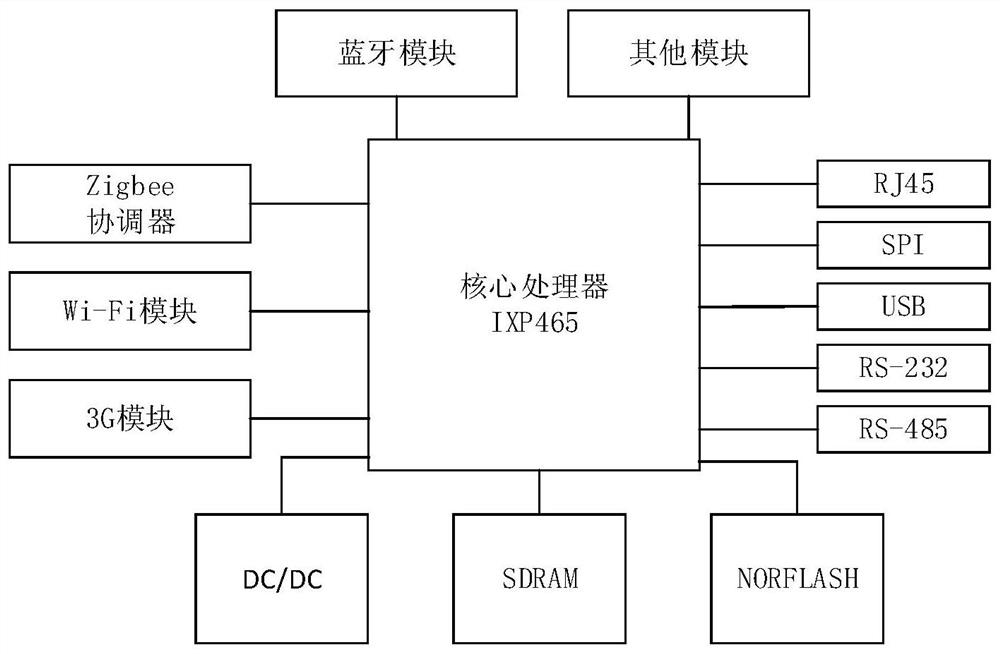

[0042] Design an intelligent gateway that supports multi-communication protocol conversion to connect with the data acquisition node, and convert the information collected by the data acquisition node to the communication protocol to realize communication with the network layer and networking of various devices;

[0043] Build an SDN network architecture, configure the software of the edge intelligent gateway, so that it can perform data conversion and transmission between different communication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com