Polarizing plate and optical display device comprising same

A polarizing plate and polarizing film technology, applied in the field of polarizing plates, can solve problems such as the degradation of heat resistance and heat resistance of polarizing plates, and achieve excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0111] Next, the present invention will be explained in more detail with reference to some examples. It should be understood that these examples are provided for illustrative purposes only and should not be construed as limiting the invention in any way.

[0112] The details of the components used in the following examples and comparative examples are as follows:

[0113] (A) Adhesive resin

[0114] (A1) Adhesive resin: a (meth)acrylic copolymer comprising 80% by weight of butyl acrylate and 20% by weight of 2-hydroxyethyl acrylate, its weight average molecular weight: 1,400,000 g / mol, glass before curing Transformation temperature: -30°C

[0115] (A2) Adhesive resin: 1335B (Sanwa Paint Co., Ltd., glass transition temperature before curing: 50°C)

[0116] (B) curing agent

[0117] (B1) Curing agent: toluene diisocyanate (toluene diisocyanate)-based curing agent Coronate L (Japan Polyurethane Industry Co., Ltd., does not contain allophanate groups)

[0118] (B2) Curing age...

preparation example 1

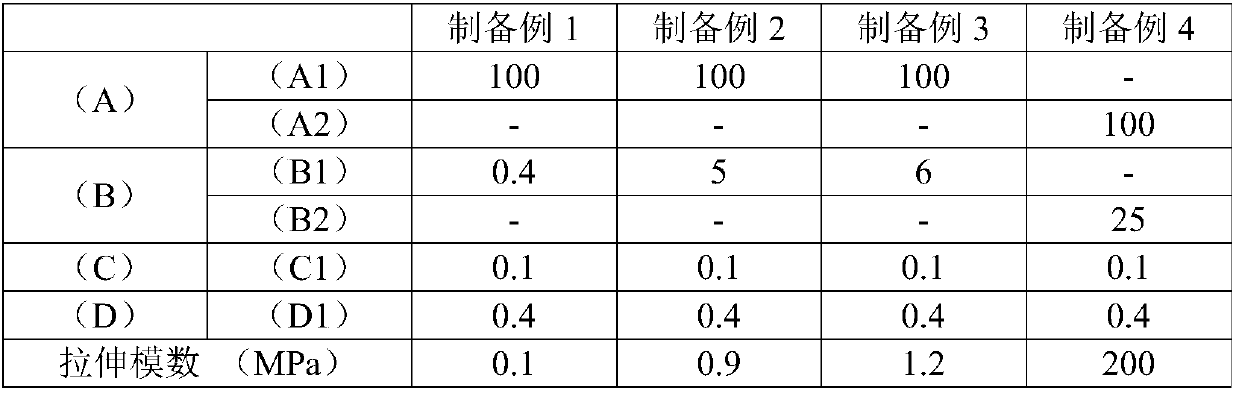

[0124] 100 parts by weight of (A1) adhesive resin, 0.4 parts by weight of (B1) curing agent, 0.1 parts by weight of (C1) silane coupling agent and 0.4 parts by weight of (D1) ultraviolet absorber were mixed to prepare an adhesive Agent layer composition.

preparation example 2 to preparation example 4

[0126] The adhesive layer composition was prepared in the same manner as in Preparation Example 1, except that the types and amounts of the adhesive resin, curing agent, silane coupling agent, and ultraviolet absorber were changed as listed in Table 1 (unit: parts by weight).

[0127] Adhesive layers were prepared using each of the adhesive layer compositions prepared in Preparation Example 1 to Preparation Example 4, and the tensile modulus of the adhesive layer was evaluated. The tensile modulus of the adhesive layer was measured by tensile stress-strain test according to ASTM D882. Specifically, the adhesive layer composition was coated on the release film in a predetermined range, then dried at 90° C. for 30 minutes, and then the release film was removed, thereby obtaining an adhesive layer with a thickness of 35 μm . The adhesive layer was cut into a size of length×width (5 mm×200 mm), whereby a sample was prepared. Both ends of the sample were fixed to clamps of a meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com