Three-mode optimal dust collector filter bag

A vacuum cleaner and filter bag technology, which is applied in the field of three-mode optimized vacuum cleaner filter bags, can solve the problems that the size of the filter bag cannot be expanded infinitely, the filter bag cannot be used, and the structure of the dust filter bag is complicated, so as to achieve high utilization rate and dust absorption. The effect of large volume and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

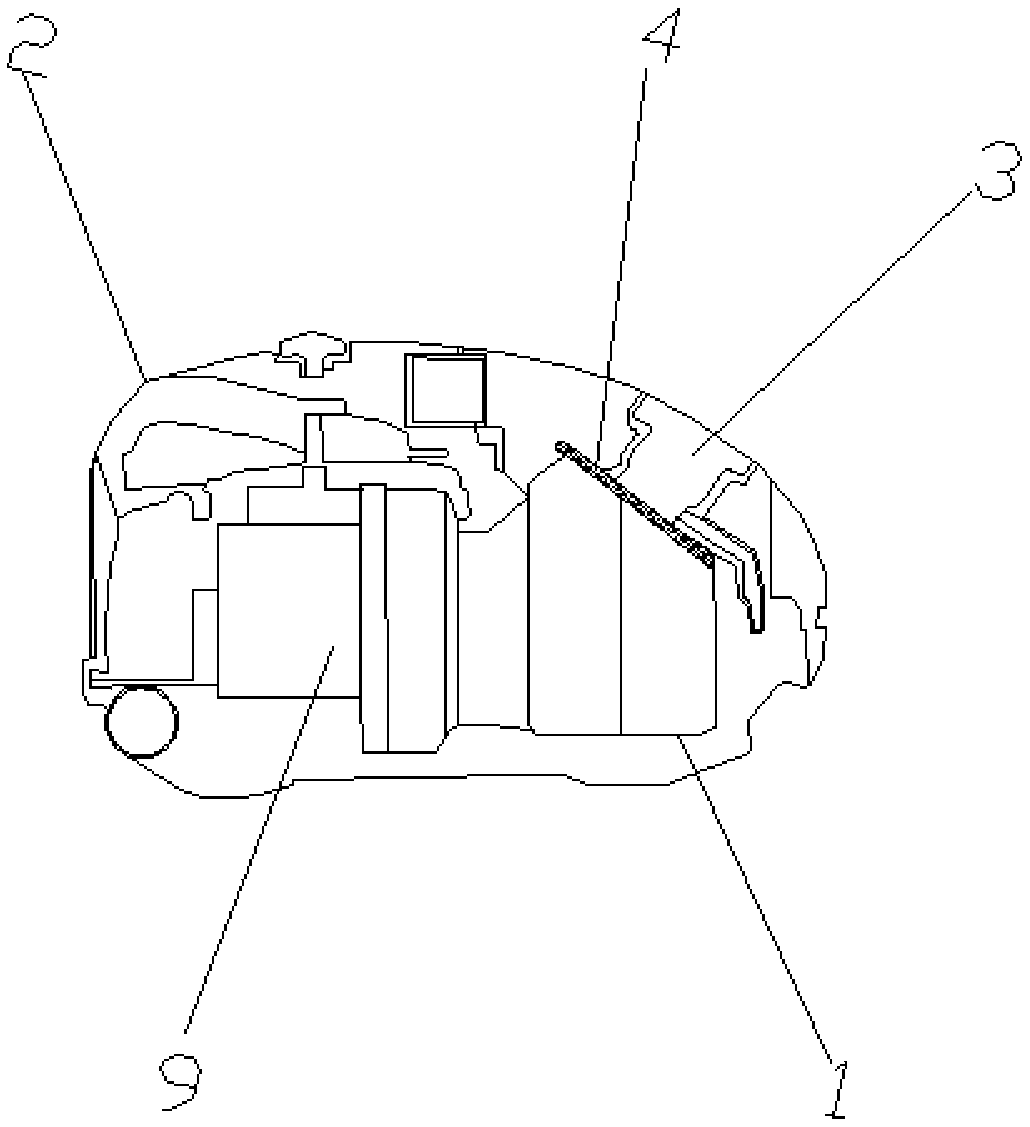

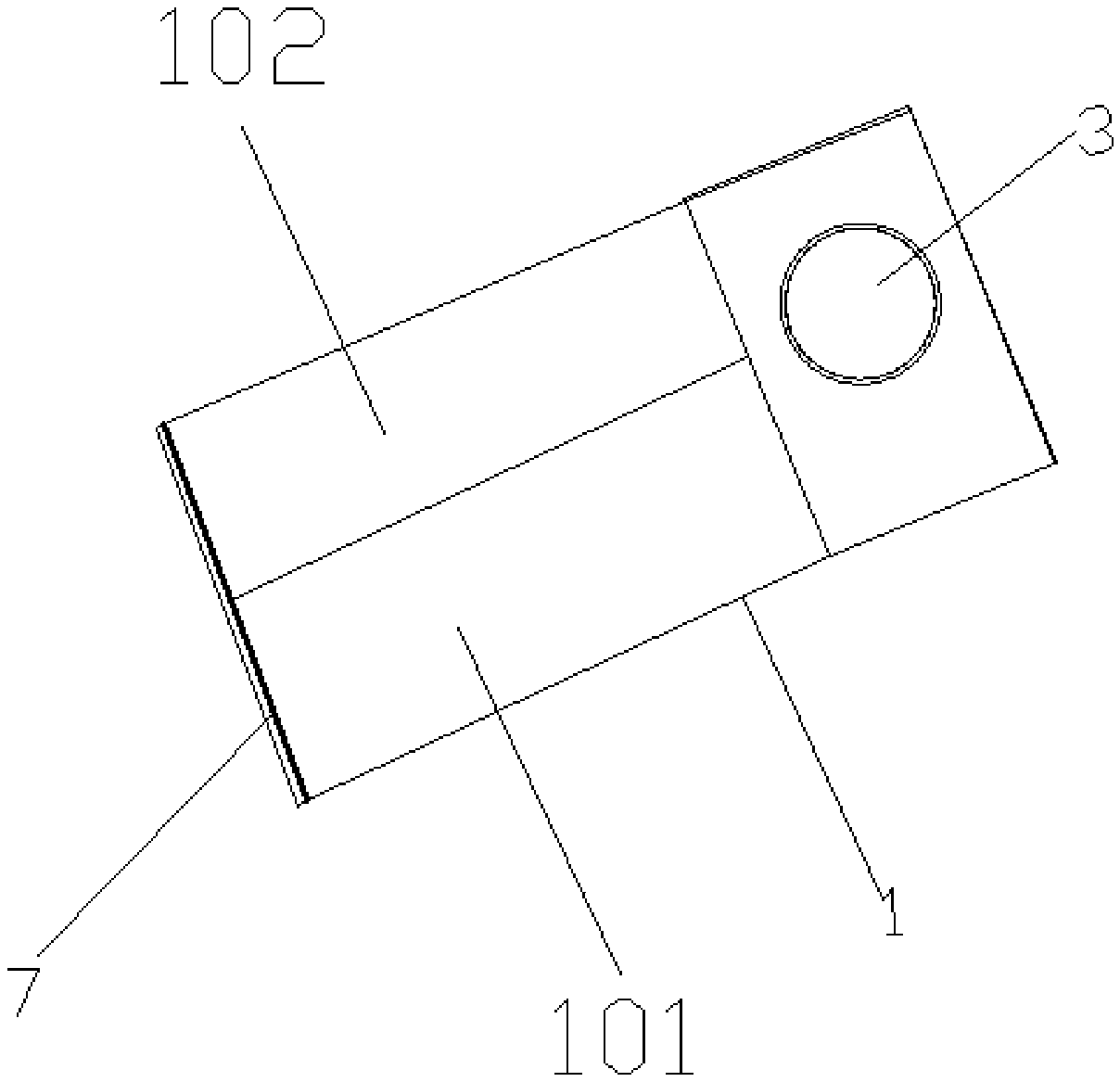

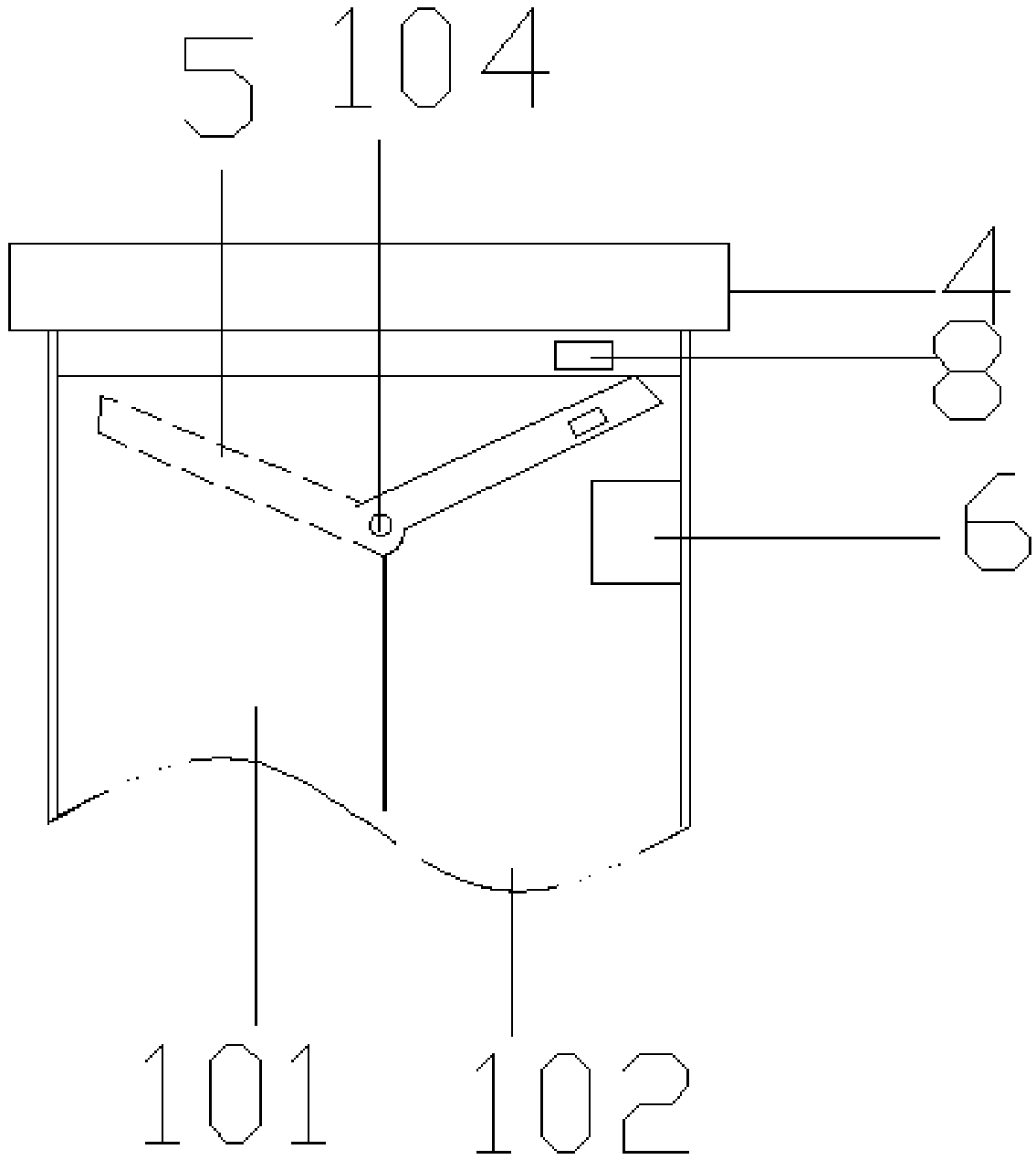

[0046] In actual use, the motor 9 of the vacuum cleaner 2 rotates at high speed to inhale air from the air inlet 3, and the filtered matter enters the dust filter bag 1 in the vacuum cleaner through the suction pipe of the vacuum cleaner 2, and the filtered matter is left in the dust filter bag 1, and the filtered matter passes through the air inlet. 3 Enter the first dust filter bag 101, the originally folded first dust filter bag 101 is unfolded and filtered under the action of the motor 9, at this time, the second dust filter bag 102 is folded, and does not occupy the space of the vacuum cleaner, (as attached Image 6 shown), when the induction switch 6 arranged on the first dust filter bag 101 senses that the first dust filter bag 101 is filled with the filter material, the induction switch 6 sends a signal to the stepping motor 10 arranged on the bracket 4, and the stepping The motor 10 drives the rotating shaft 104 so that the flap 5 turns over to the first dust filter ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com