Protective device and method for uranium enrichment plant material container disassembly and assembly operation

A protective device and container technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of high operating costs, large load of local exhaust fans, and inconvenient operation, so as to reduce radioactive pollution and construction investment , the effect of reducing manpower waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

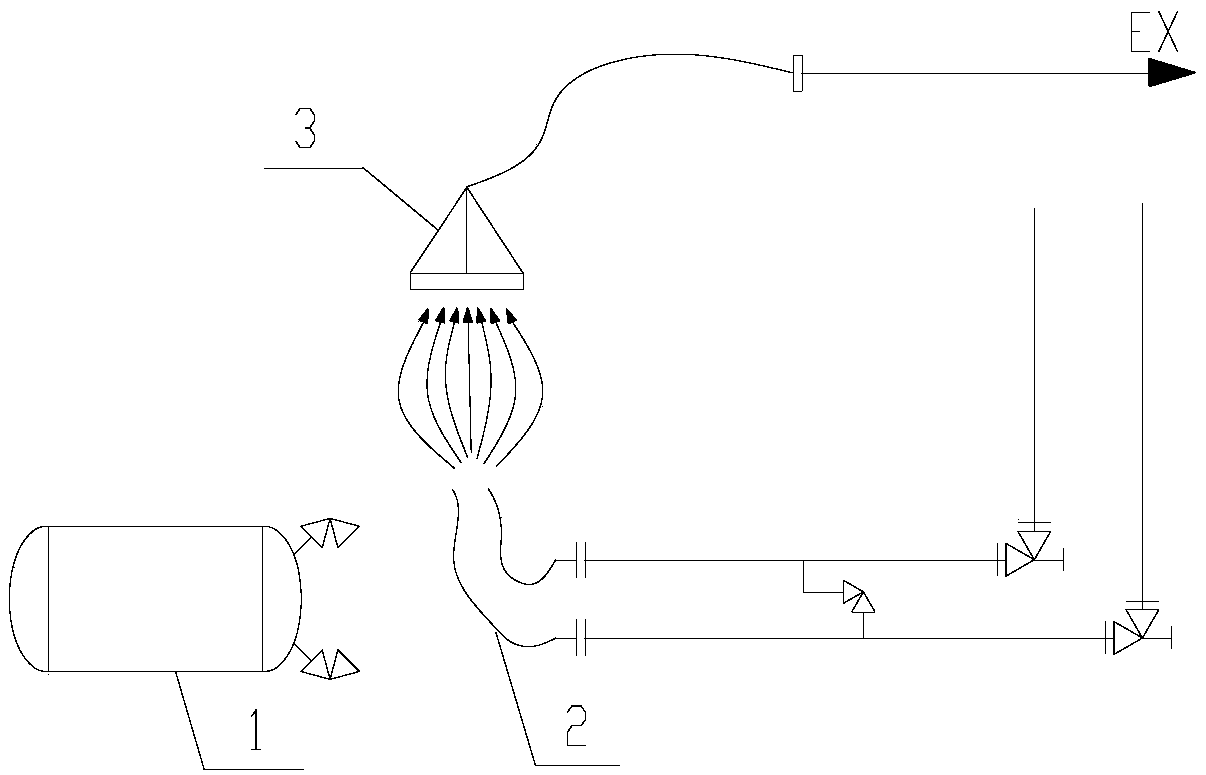

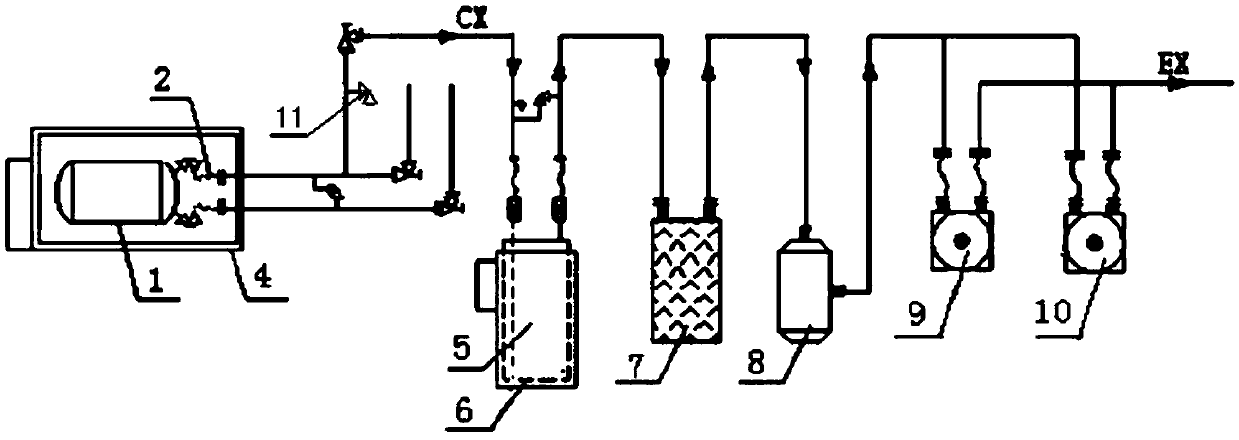

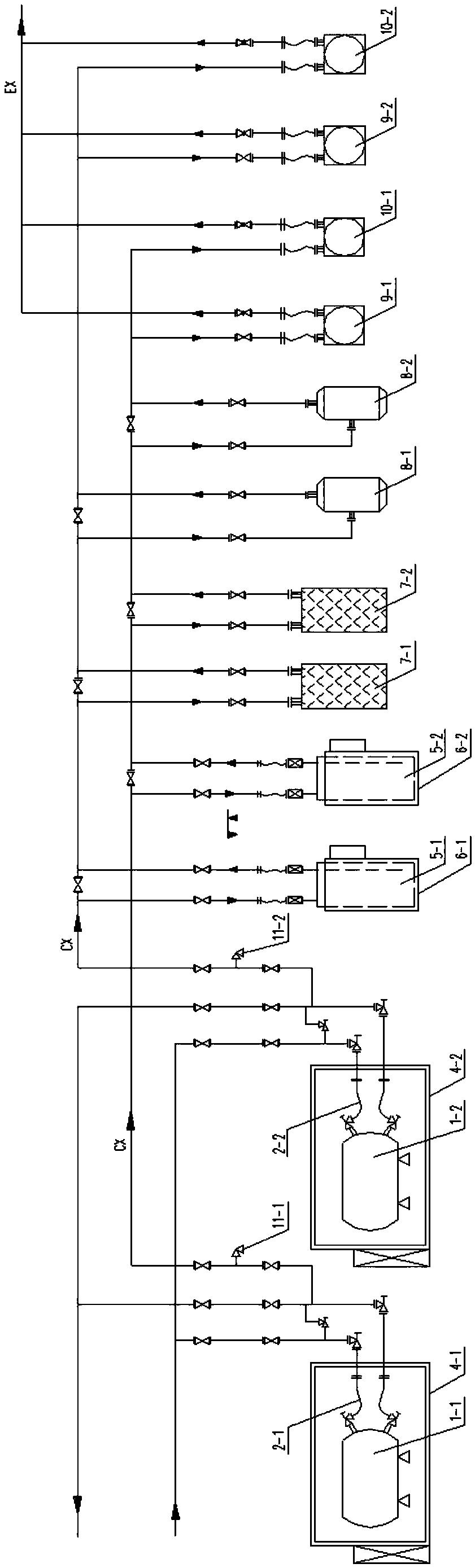

[0067] Such as image 3 As shown, a protective device for the disassembly and assembly operation of the material container in the uranium enrichment plant is used to separately connect the container connecting pipe A2-1 and the container when the material container A1-1 and the material container B1-2 are disassembled in the material supply and reclaiming plant. Connect the tube B2-2 for evacuation and purging. Taking the disassembly and assembly of the material container A1-1 as an example, the protective device A includes the breach valve A11-1 for purging, the condenser A5-1, the small cryogenic box A6-1, the adsorption tower A7-1, and the filter A8 -1. Jet pump A9-1, vacuum unit A10-1 for evacuation.

[0068] The container connection pipe A2-1 is connected in series with the vent valve A11-1 for purging, the condenser A5-1, the adsorption tower A7-1 and the filter A8-1 in sequence, and then connected with the jet pump A9-1 and the filter A8-1 respectively. Vacuum unit A1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com