Multifunctional energy-saving air heating combination machine

A laminating machine, multi-functional technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problem of not being able to roll EPE at the same time, and achieve the effect of increasing the scope of use, preventing deformation, and improving the quality of lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

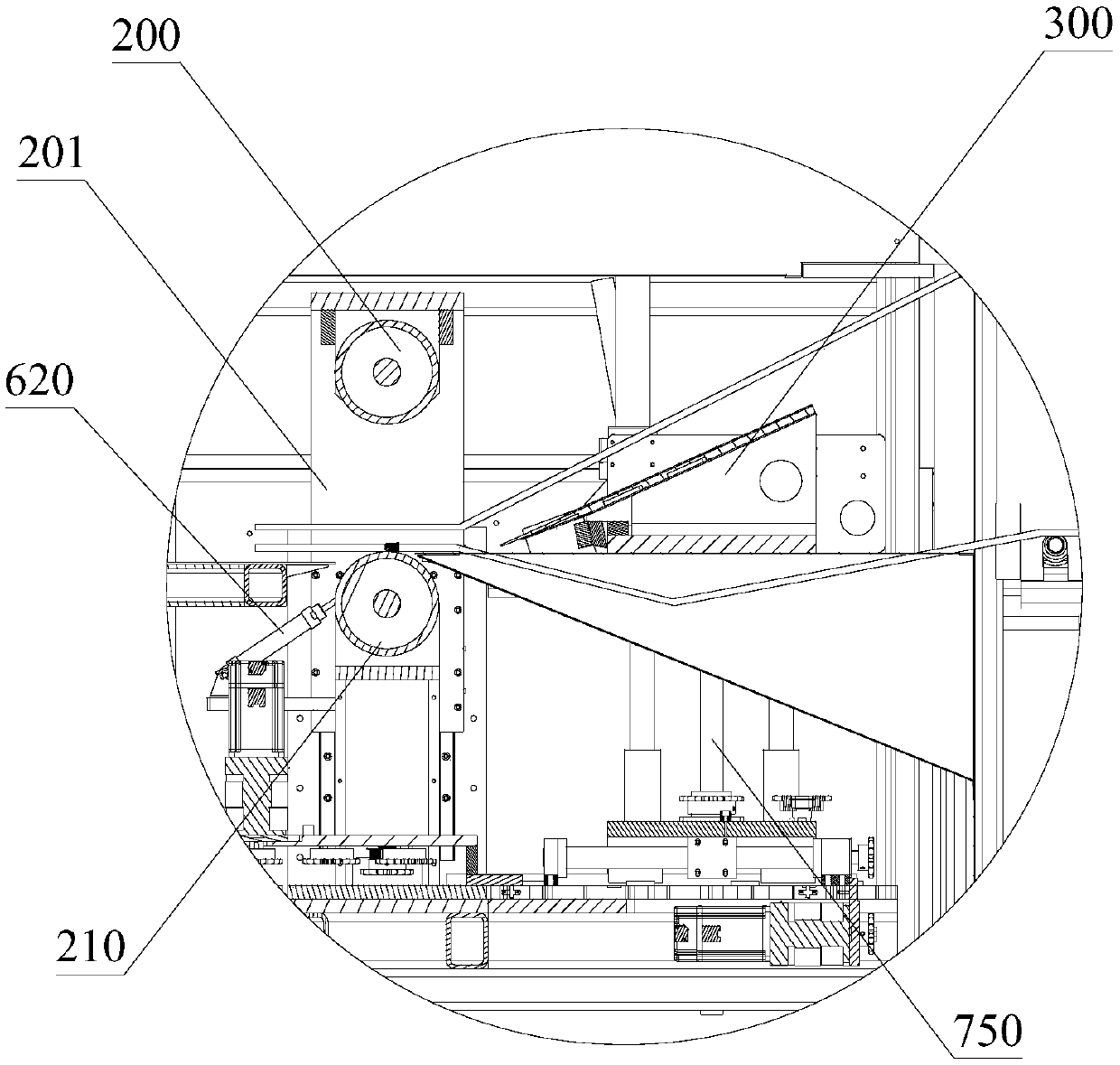

[0051] The invention provides a multi-functional energy-saving hot-air compound machine, which can compound the pearl cotton of the roll material and the pearl cotton of the sheet material, and at the same time solve the problem of the low heat utilization rate of the hot air and the low flatness of the surface after compounding in the existing hot-air compound machine The problem. The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

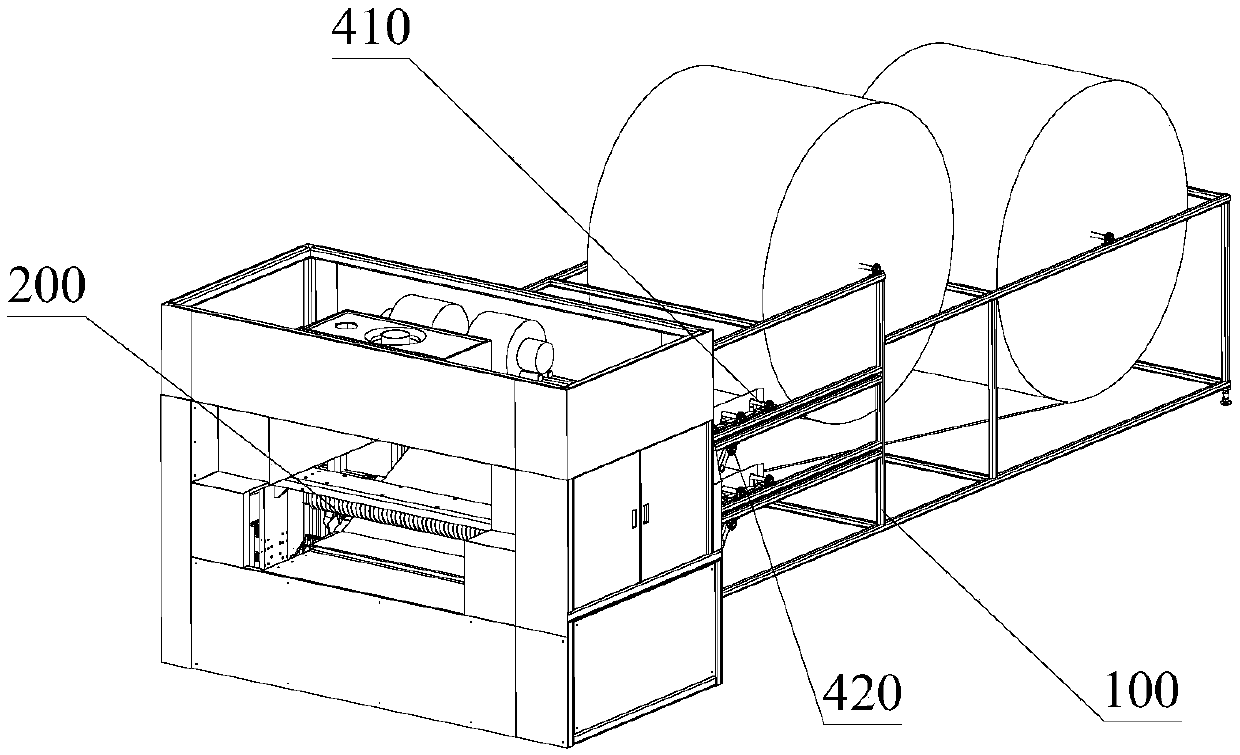

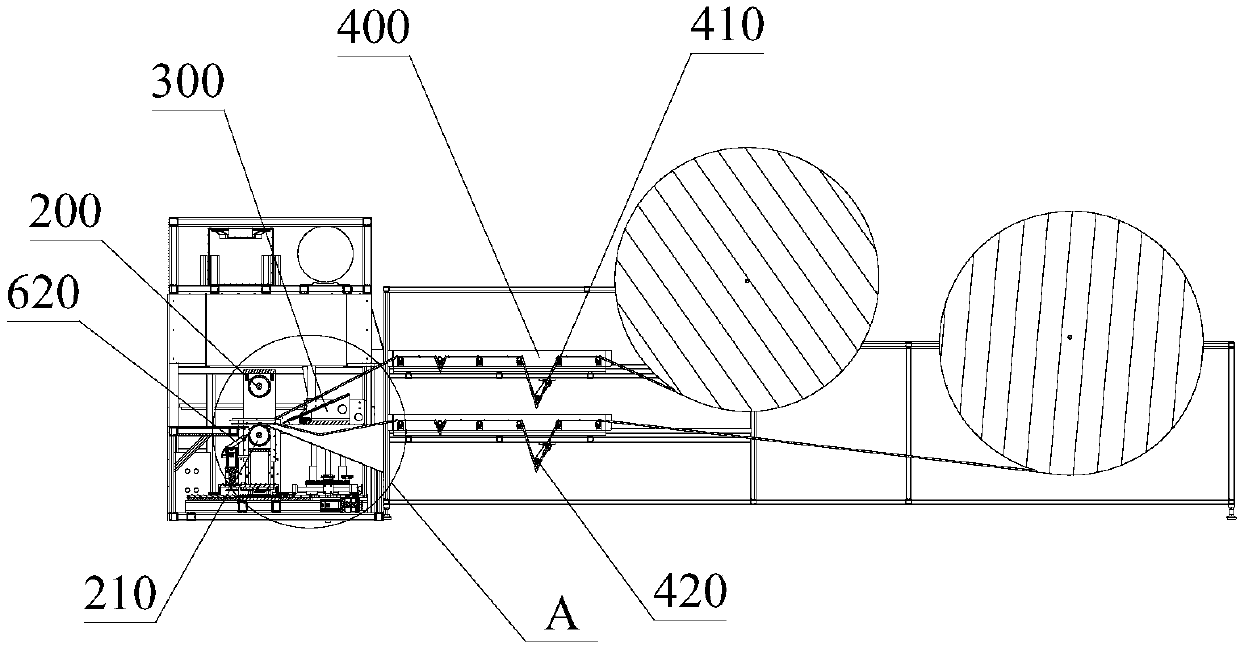

[0052] Such as Figure 1 to Figure 9 As shown, a multi-functional energy-saving hot air composite machine provided by the present invention includes a frame 100, on which a pressure roller seat, a hot air ejection seat 300, and a pearl cotton guide device are arranged. And the frame 100 is provided with a rotating shaft for placing the roll material pearl cotton.

[0053]Such as figure 2 and image 3 As shown, the pressure roller seat rotates in the vertical directio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap