Bottom supporting steel beam threading equipment and method for salvaging sunken ship

A technology for supporting the bottom and steel beams, which is used in ship salvage, ships, transportation and packaging, etc. It can solve the problems of the inability to accurately correct the deviation of steel beams, the weight of steel beams, and the penetration of steel beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

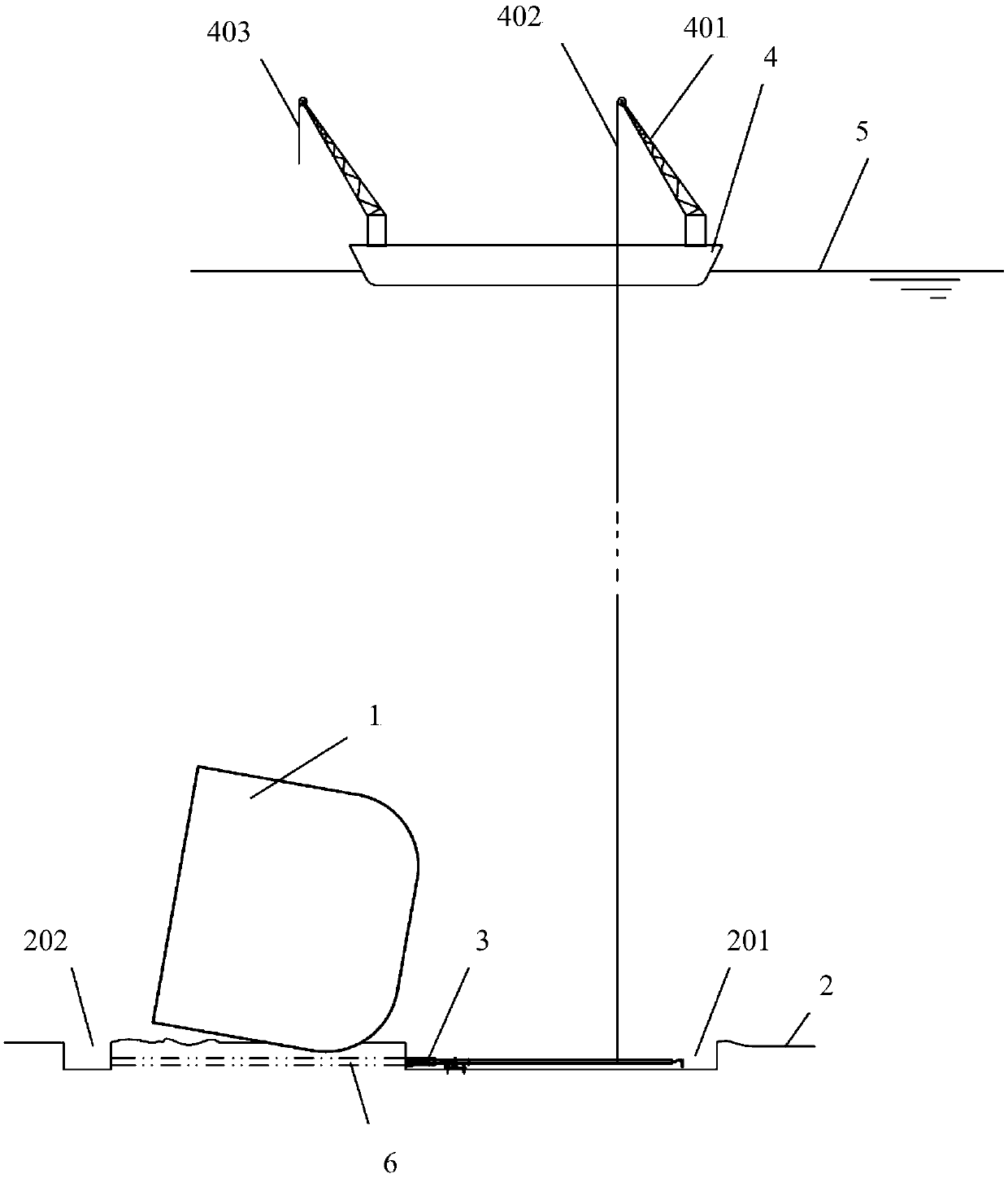

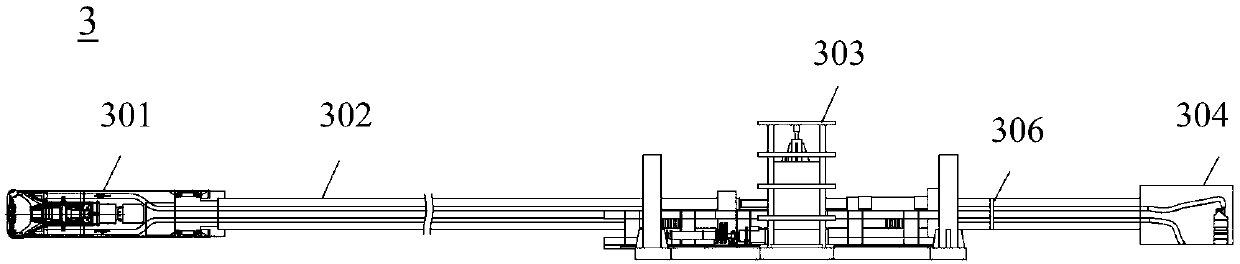

[0029] The present invention is introduced below by accompanying drawing.

[0030] It should be noted that, in this application, for the convenience of description, the direction of excavation advancement of the main engine in the underpinning steel beam penetration equipment is defined as front end or similar terms, and the direction opposite to the direction of excavation advancement of the main engine is defined as rear end. terminal or similar terms. And it is not used to limit the absolute position of the components involved, but can be changed according to specific situations.

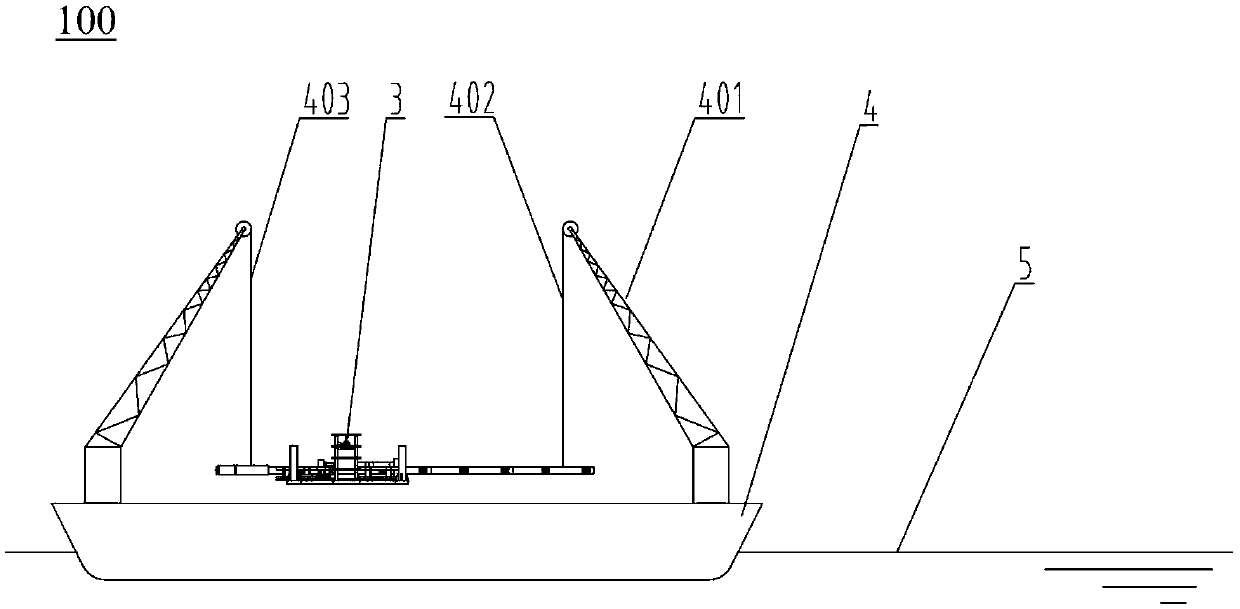

[0031] figure 1 An overall schematic diagram of the underpinning steel girder threading device 100 for salvaging sunken ships according to the present invention is shown. like figure 1 As shown, the underpinning steel girder threading equipment 100 includes a working boat 4 on the water surface 5 , and a crane 401 is arranged on the working boat 4 . The underpinning steel beam threading equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com