Flue gas distributor

A distributor and flue gas technology, which is applied in chemical instruments and methods, special treatment targets, water/sewage treatment, etc., can solve the problem of uneven mixing of flue gas and atomized wastewater, and it is not suitable for bypass evaporation of power plant wastewater , impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

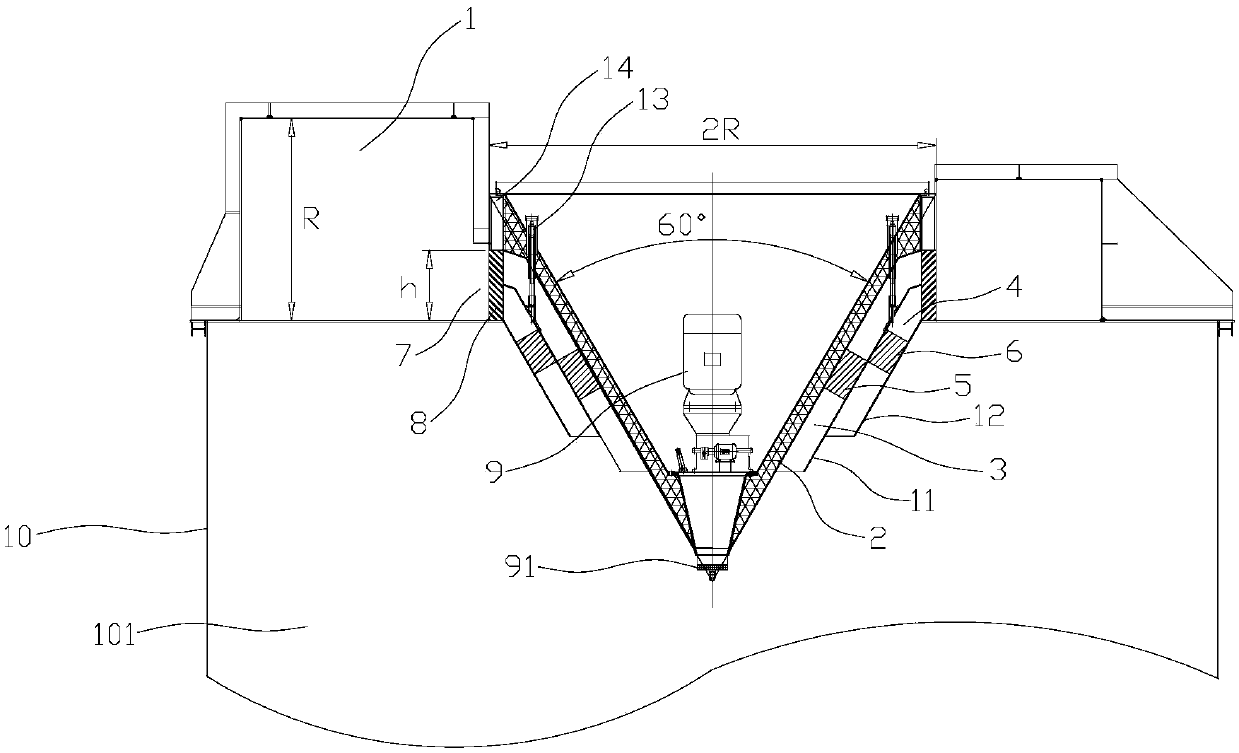

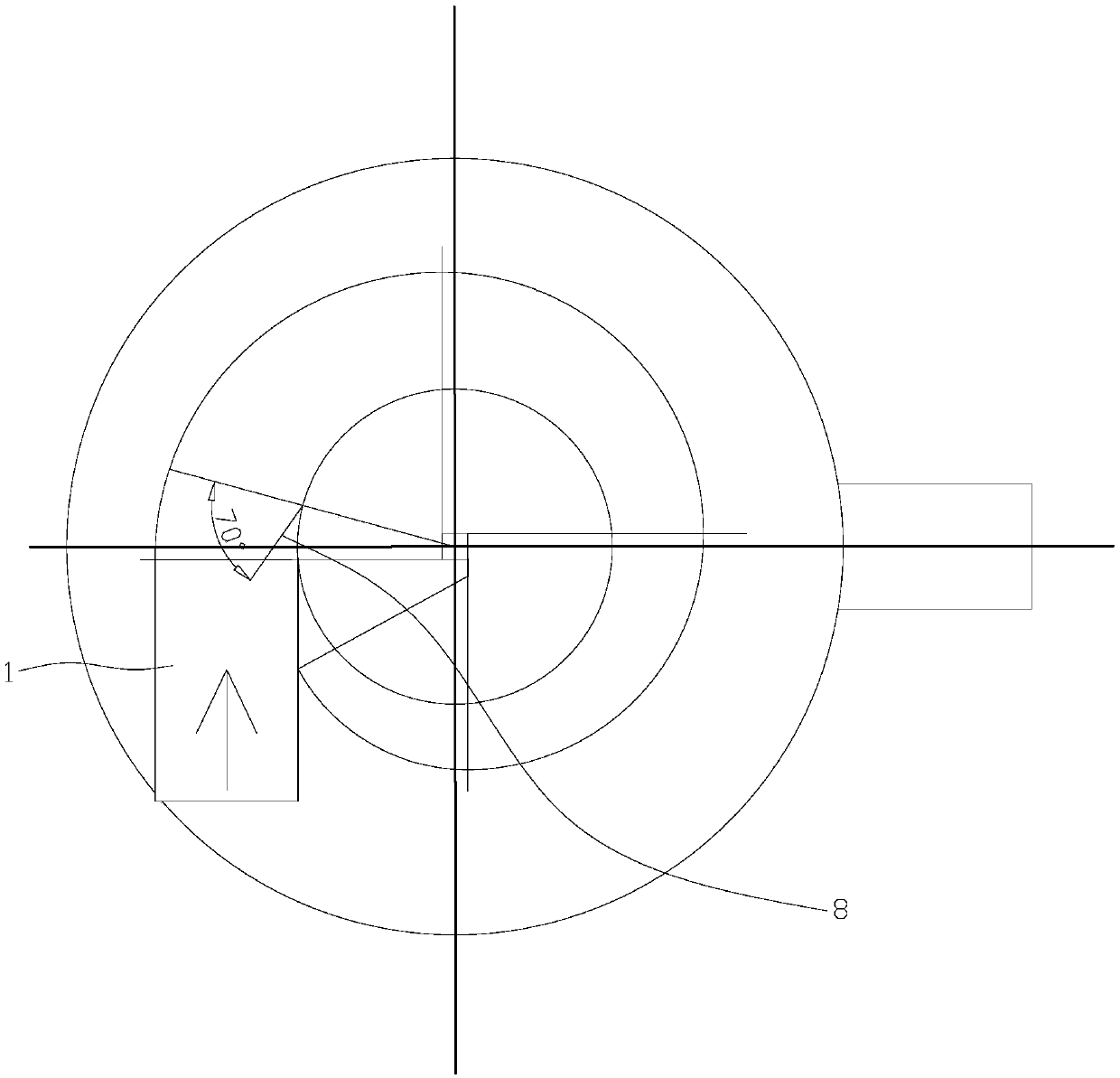

[0017] Such as figure 1 As shown, a flue gas distributor includes a volute-shaped equal pressure air chamber 1 arranged on the top of the evaporation tower 10 and a flue gas distributor inside the equal pressure air chamber 1. The entrance of the equal pressure air chamber 1 is sideways. A square with a length of R, the smoke distributor includes a cone-shaped distributor body 2, a double-layer air flow channel surrounding the outside of the distributor body 2, and the diameter of the top surface of the distributor body 2 is 2R. The double-layer airflow channel is composed of an inner layer annular airflow channel 3 and an outer layer annular airflow channel 4 with a tapered cross-section and are mutually isolated, the upper and lower ends of the inner layer annular airflow channel 3 and the outer layer annular airflow channel 4 Open, the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com