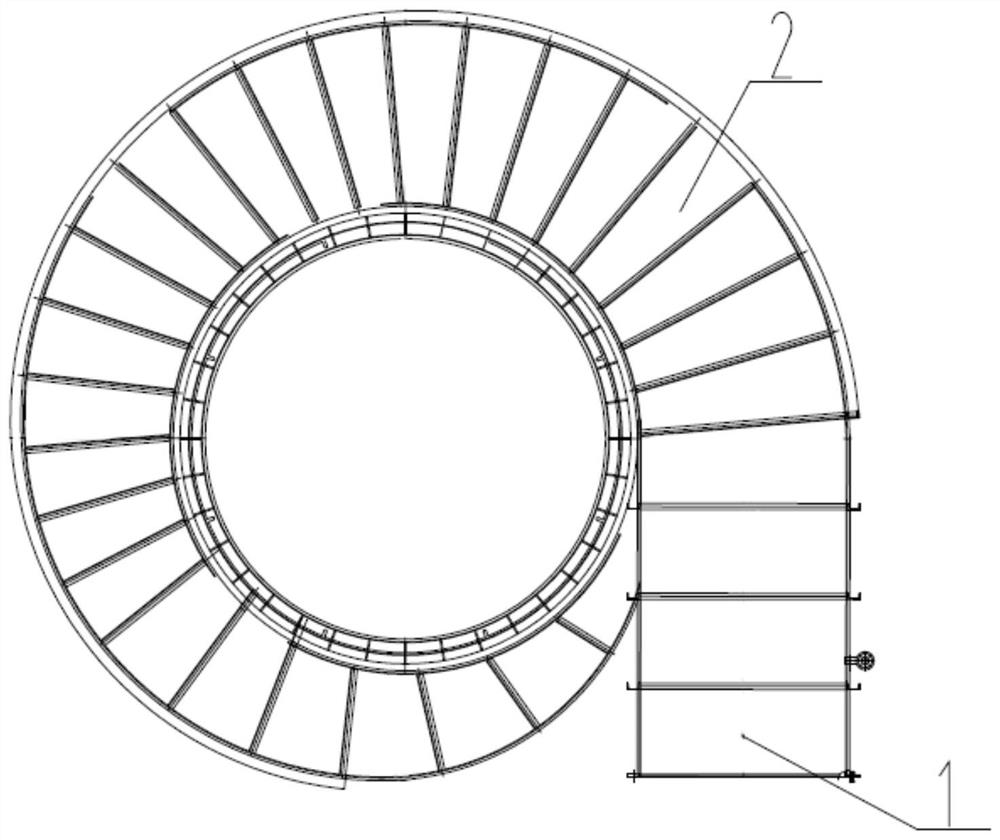

Novel flue gas distributor for rotary spray wastewater drying

A rotary spray and rotary atomizer technology, which is applied in gaseous discharge wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of uneven distribution of flue gas entering the tower, insufficient mixing of atomized wastewater, Incomplete evaporation and other problems, to achieve good evaporation and drying effect, good mass transfer and heat transfer effect, and the effect of improving the ability of two-phase heat and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, some modifications can be made to the present invention without departing from the principles of the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

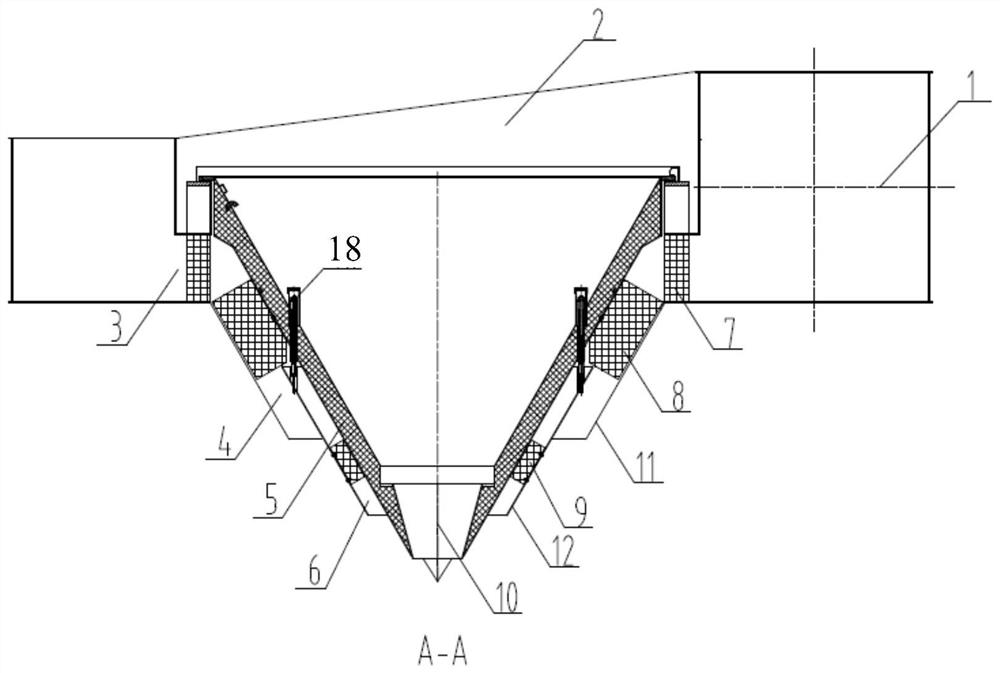

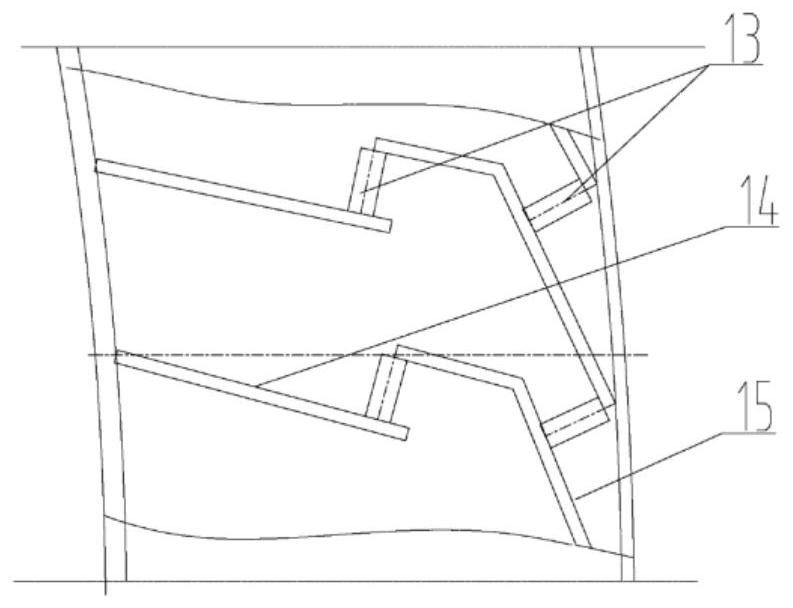

[0023] The invention provides a new type of flue gas distributor for rotary spray wastewater drying, innovates the deflector structure and channel structure, and designs a distributor suitable for rotary spray wastewater drying, which can enhance the swirl flow of flue gas and ensure The gas-liquid two-phase is evenly mixed to improve the heat and mass transfer capacity of the two-phase. The invention fully utilizes the heat of the flue gas to enhance the effect of evaporating wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com