Micro-power sewage treatment system

A sewage treatment system and micro-dynamic technology, applied in the direction of sterilization/micro-dynamic water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Poor stability, difficult process control and other problems, to achieve the effect of unmanned management, simple and effective structure, and short start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

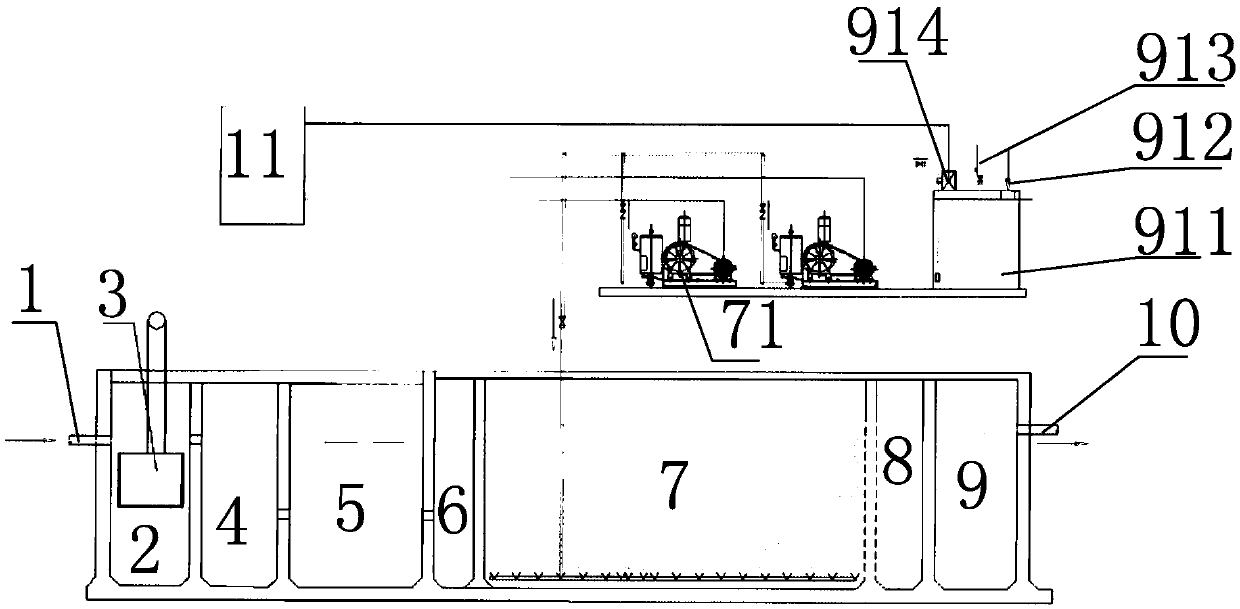

[0017] Such as figure 1 As shown, the micro-dynamic sewage treatment system has a structure including a filter tank 2, a grease trap 4, a hydraulic grit chamber 5, a rapid separation biochemical tank 7 and a disinfection discharge pond 9, wherein the filter tank 2, the grease trap 4 and the hydraulic sedimentation tank The sand tank 5 is connected through pipelines in turn, the filter tank 2 is connected with the domestic sewage inlet pipe 1, the filter tank 2 is equipped with a basket-type grille 3, the hydraulic grit chamber 5 is connected with the water distribution tank 6 through the pipeline, and the water distribution tank 6 is connected with the speed separation biochemical tank 7 The quick-separation biochemical pool 7 is filled with biological balls, the quick-separation biochemical pool 7 is connected to the aeration fan 71 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com