Method for preparing ganglioside through efficient hydrolysis conversion

A ganglioside, high-efficiency technology, applied in chemical instruments and methods, preparation of sugar derivatives, organic chemistry, etc., can solve problems such as short supply and achieve the effect of improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

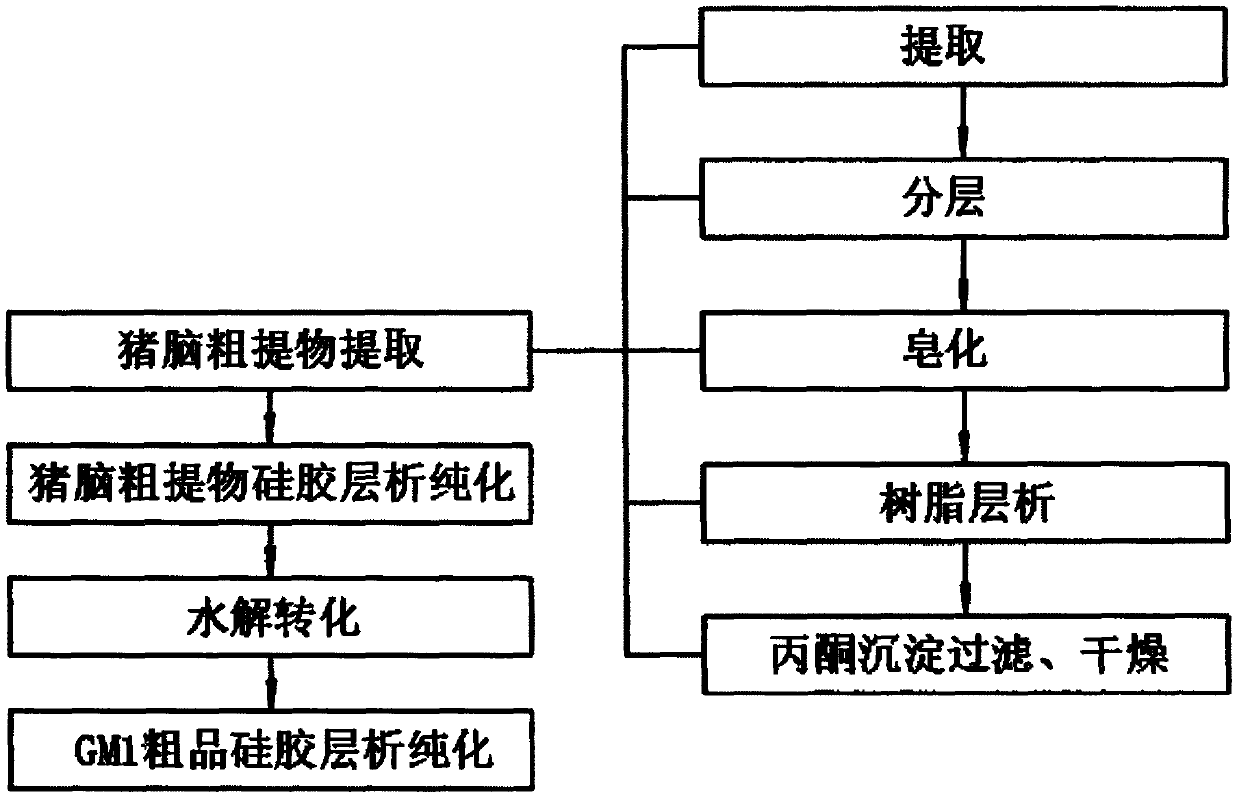

[0023] The method for preparing gangliosides by efficient hydrolysis conversion comprises the following steps:

[0024] Step 1: Pig brain crude extract extraction:

[0025] Extraction: Grind the fresh pig brain, add the extract solution (chloroform / methanol = 1:2) into the extraction tank at a ratio of 1:3 (w / v), heat at 40°C, stir and extract for 30 minutes, and let the layers stand for 40 minutes , filter press, collect supernatant and filtrate;

[0026] Stratification: add drinking water according to 25% of the volume of the extract, stir for 10 minutes, let stand for 12 hours to separate the layers, and collect the supernatant;

[0027] Saponification: add 0.3% of the volume of the supernatant to solid sodium hydroxide in a layered hydrolysis tank, control the temperature at 55-65°C, and stir for 30 minutes;

[0028] Resin chromatography: pass the hydrolyzate through the macroporous resin, wash the resin with 2 times the column volume of water, then wash the resin with 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com