Construction machinery for backfilling coal mining roadway

A technology for construction machinery and roadways, which is applied in tunnels, fillings, tunnel linings, etc., can solve the problems of low density and strength of filling bodies, low utilization rate of coal gangue, and influence on governance work, and achieve considerable economic benefits. Improvement of backfill efficiency and elimination of filling voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described with reference to the drawings and embodiments.

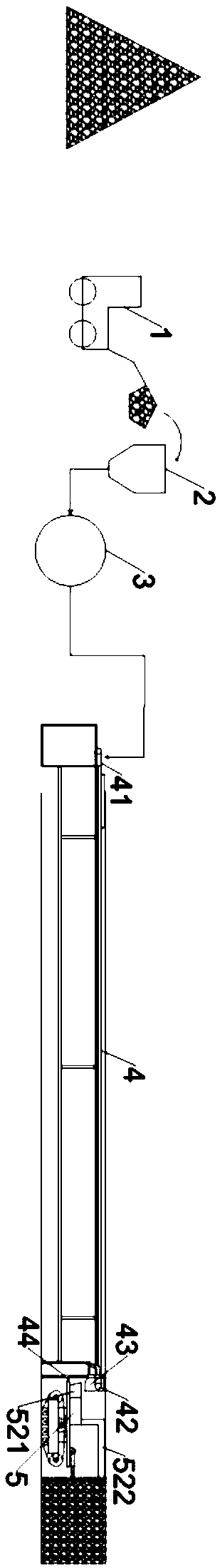

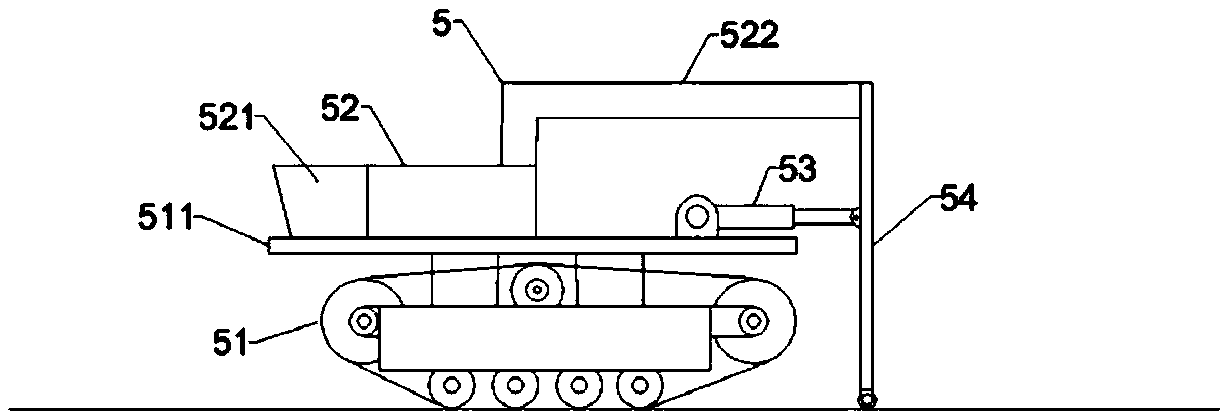

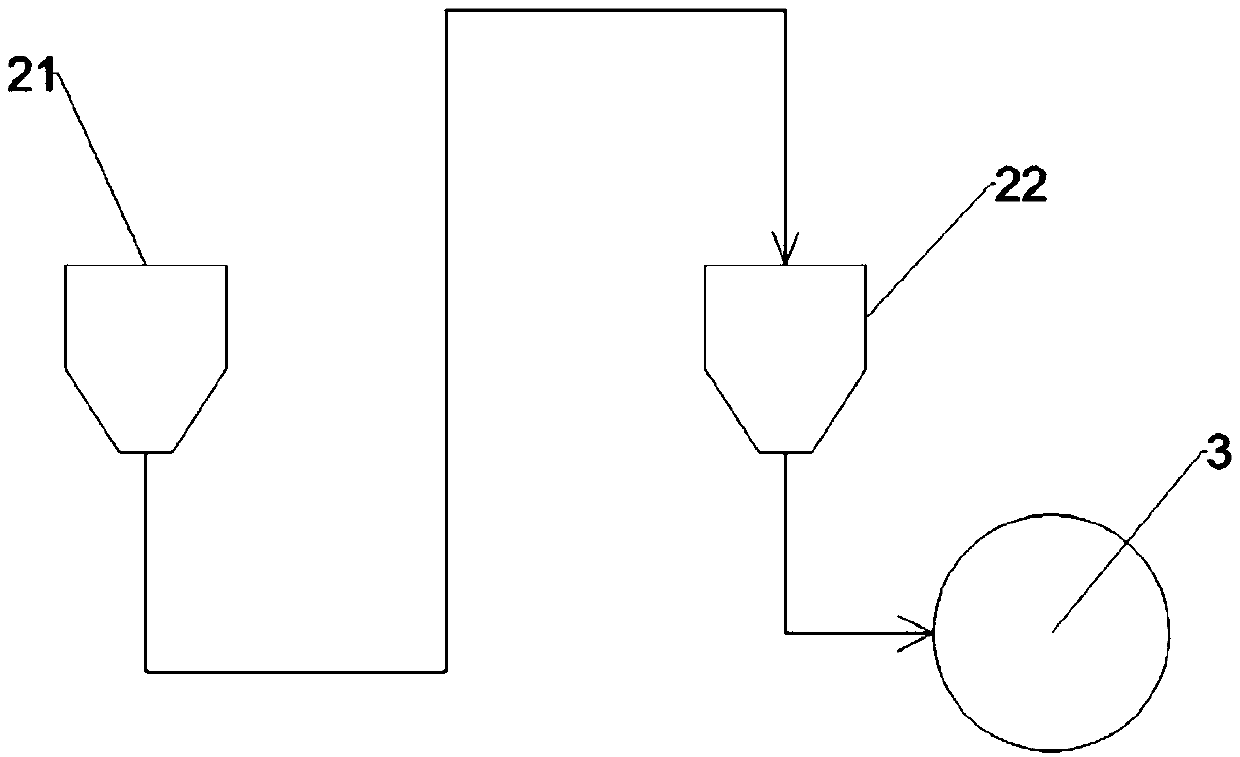

[0028] In one embodiment, as Figure 1-2 Shown, a kind of construction machine of backfilling coal mining roadway, comprises the machinery described as follows: forklift 1, pulverizer 2, mixer 3, belt conveyor 4, grouting truck 5, with described forklift 1 to described The feed port of the pulverizer 2 is filled with material, the discharge port of the pulverizer 2 is connected with the feed port of the mixer 3 through a chute, and the discharge port of the mixer 3 is connected with the belt conveyor 4 through a conveyor belt. The tail 41 of the machine is connected, and the discharge port of the discharge hopper 43 of the head 42 of the belt conveyor 4 communicates with the feed port of the feed hopper 521 of the concrete pump 52 of the grouting truck 5, and the concrete pump The conveying pipe 522 of 52 communicates with the backfill space in front of the baffle 54 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com