Non-return temperature-control valve and modular environment-friendly fuel filter adopting same

A technology of temperature control valve and check, applied in the direction of machine/engine, liquid fuel feeder, fuel heat treatment device, etc., can solve the problem of increasing equipment volume and connection complexity, not being able to adapt to the limited space inside the car, and difficult to distinguish fuel and water problems, to achieve the effect of simple structure, eliminating resistance and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

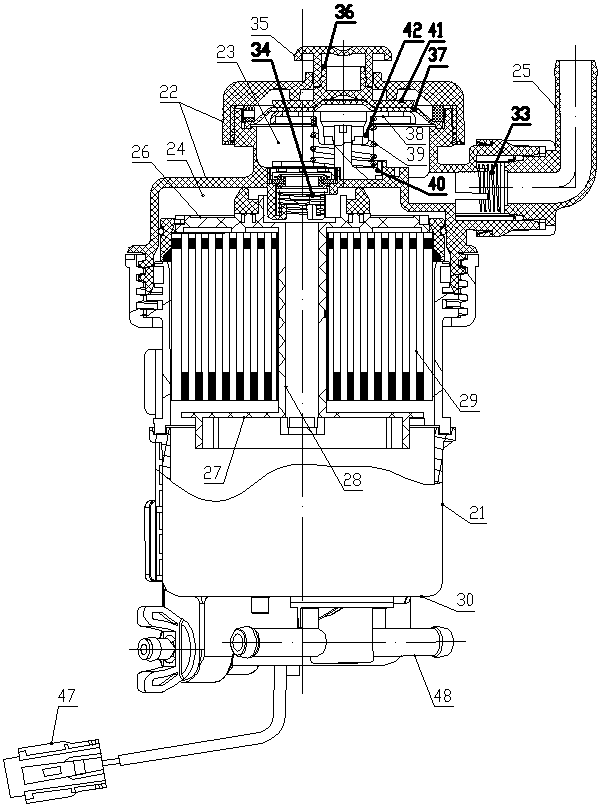

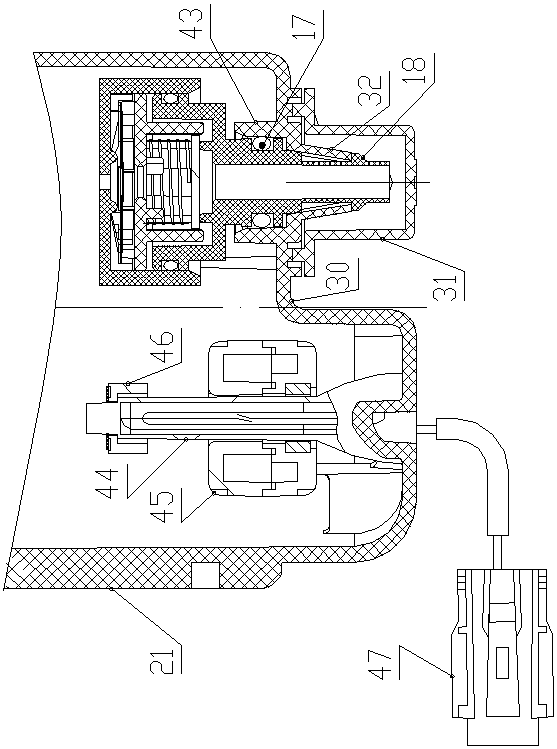

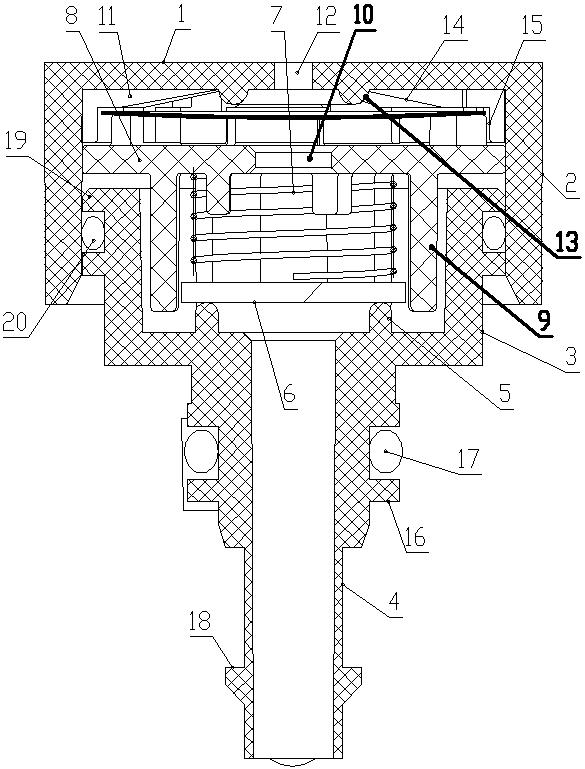

[0036] Such as Figure 1 to Figure 4 As shown, the non-return temperature control valve of the present invention includes a valve seat and a valve cover. The valve cover includes a valve cover top wall 1. The valve cover top wall 1 is integrally connected downwardly with a cylindrical valve cover side wall 2, and the valve seat includes The upper cylinder 3 with the top open, the bottom middle of the upper cylinder 3 is integrally connected with the lower round pipe 4 downwards, and the bottom of the lower round pipe 4 is open; the valve cover is arranged on the upper cylinder 3 and is connected with the upper cylinder 3 The outer wall is sealed and matched;

[0037] The bottom of the upper cylinder 3 is provided with an annular support seat 5 upwards, and the top end of the lower round tube 4 is open in the annular support seat 5; the center of the annular support seat 5 is located on the axis of the lower round tube 4 and the ring support seat 5 The inner diameter is greater t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com