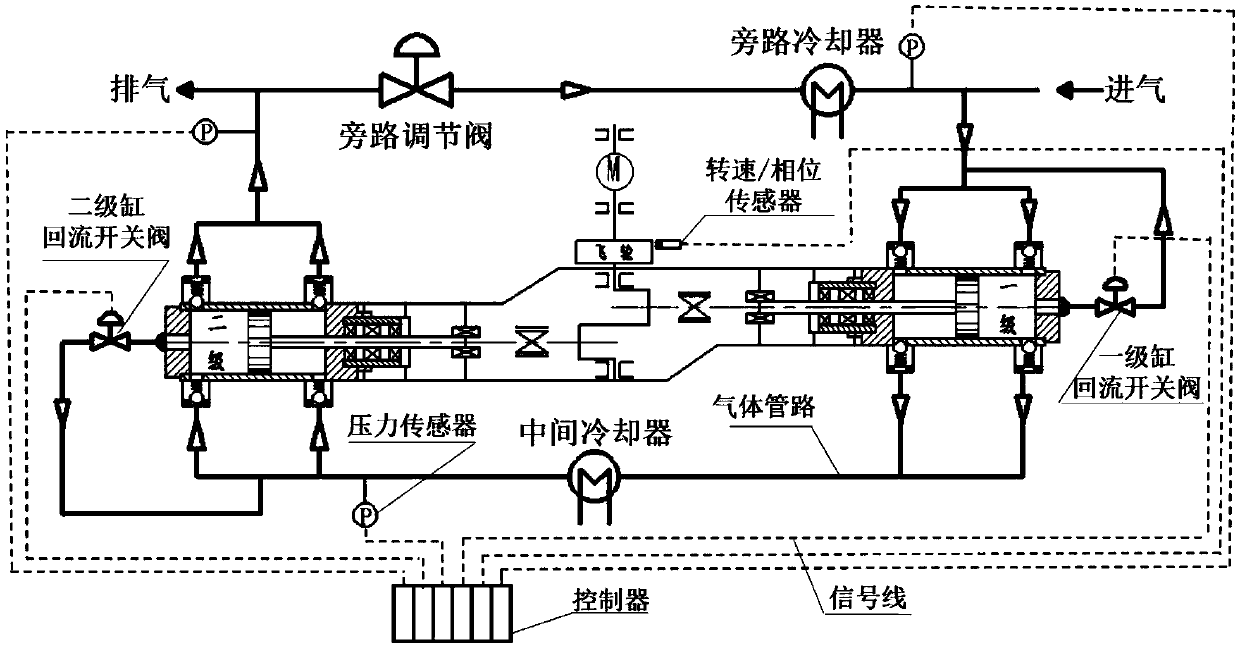

Cylinder head bypass backflow type piston compressor gas amount stepless adjustment method

A stepless regulation, compressor technology, applied in multi-stage pumps, mechanical equipment, machines/engines, etc., can solve the problems of extremely high fatigue life requirements of actuators, high investment and maintenance costs, and high actuator costs. Simple structure, low cost, and significant reduction in energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

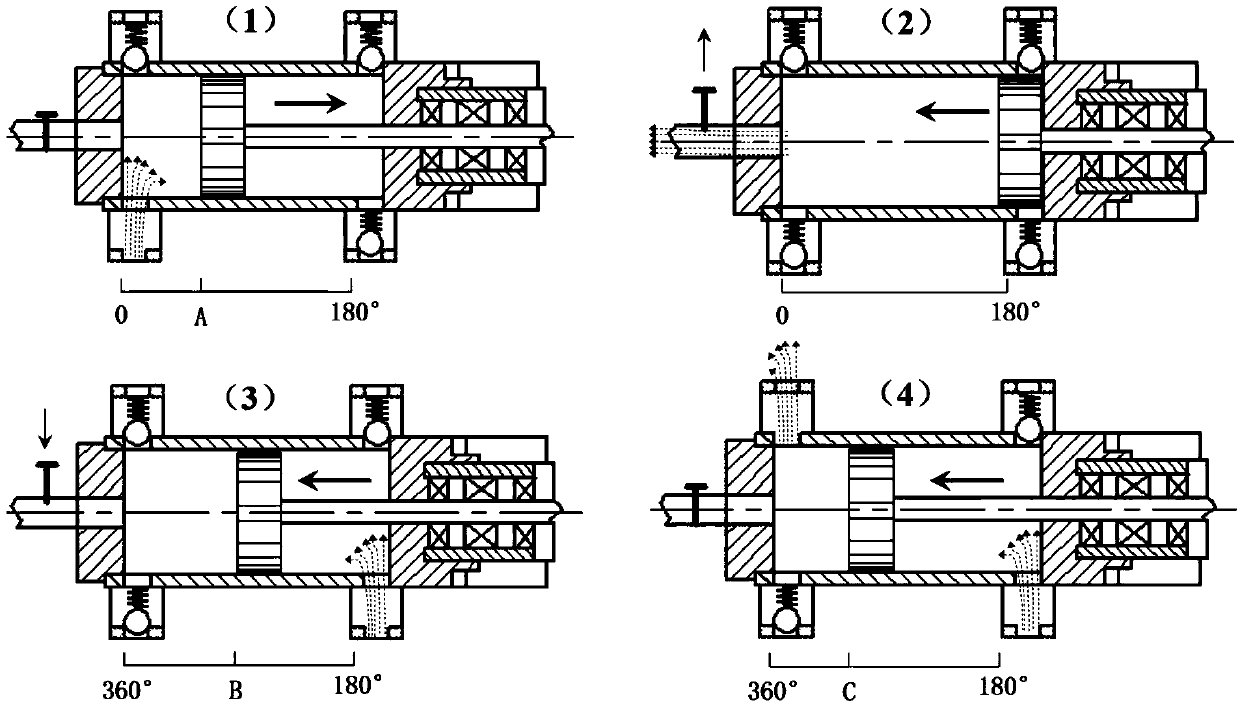

Method used

Image

Examples

Embodiment example

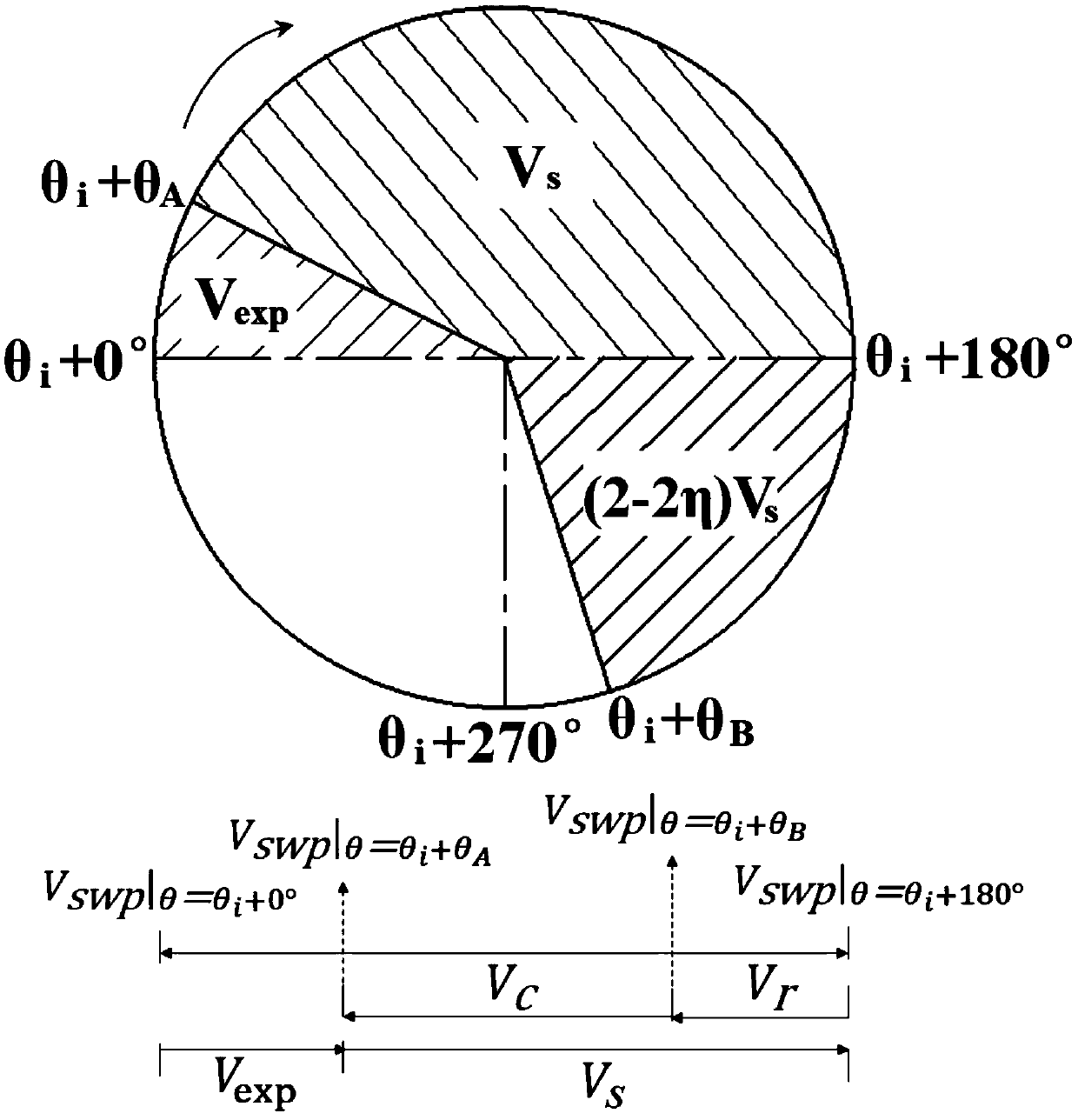

[0041] Take a 2D two-row two-cylinder reciprocating compressor with a working speed of 500r / min, a rated suction pressure of 0.1MPa, and a rated discharge pressure of 0.3MPa as an example.

[0042] The working speed of the compressor is n=500r / min

[0043] Number of cylinders N=2

[0044] The absolute phase angle of each cylinder piston when it reaches the outer dead center is θ i =0°(i=1~2)

[0045] Crankshaft radius r=90mm

[0046] Connecting rod length l=450mm

[0047] Crank connecting rod ratio λ=0.2

[0048] Cylinder clearance volume V cle =1.26e06mm 3

[0049] The bore diameter of both cylinders is D cy =250mm

[0050] Expansion coefficient n e =1.4

[0051] Calculate the working cycle time of the compressor

[0052] The time T from when the controller outputs the switch valve opening signal to when the valve is fully opened 1 =7ms

[0053] The time T from when the controller outputs the switch valve closing signal to when the valve is completely closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com