Device for detecting the sealing performance of an automobile air storage tank

A technology for leak tightness testing and equipment, which is used in fluid tightness testing, fluid tightness measurement using liquid/vacuum, measuring devices, etc. It can solve problems such as inability to guarantee product quality and inability to effectively observe the interface to be tested, etc. Achieve the effect of improved safety protection factor, simple operation and use, and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

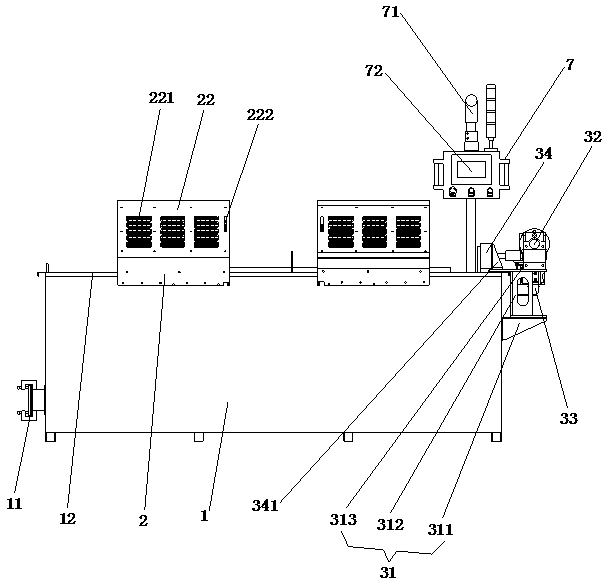

[0031] The present invention will be further described below in conjunction with specific embodiments. Wherein, the location words such as "left, right, front, back, up, down, top, bottom" involved in the present invention are all related to figure 2 The structures shown are oriented in the same way.

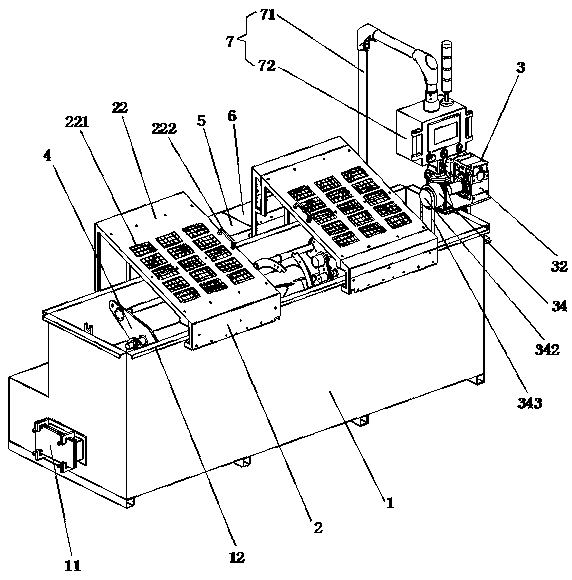

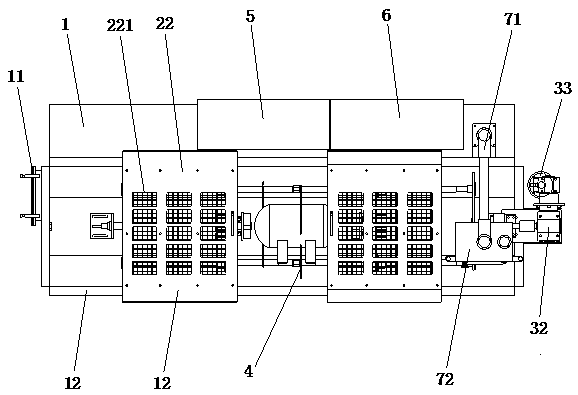

[0032] Such as Figures 1 to 12 As shown, the present invention is used for the airtightness testing equipment of automobile air storage tank, including water tank 1, protective door 2, driving mechanism 3, fixture 4, pneumatic components cabinet 5, electrical cabinet 6 and button station 7.

[0033] The water tank 1 is placed on the ground and has an accommodating space inside. Its top is open, the rear is stepped, and the lower part of the left outer wall is also equipped with a slag discharge port 11; wherein, the front, rear, left, and The outer edge of the right top notch is welded and fixed with a slide rail 12; the opening of the slide rail 11 is downward and forms an ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap