Static evaporation pressure-hold test device and method for vehicular LNG (liquefied natural gas) cylinders

A testing device and evaporation rate technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems that the operator's safety cannot be guaranteed, the real data cannot be obtained, and the data error is large, so as to avoid the risk of overpressure, save the assembly time, Real and accurate effect of flow value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following specific examples illustrate the present invention in further detail.

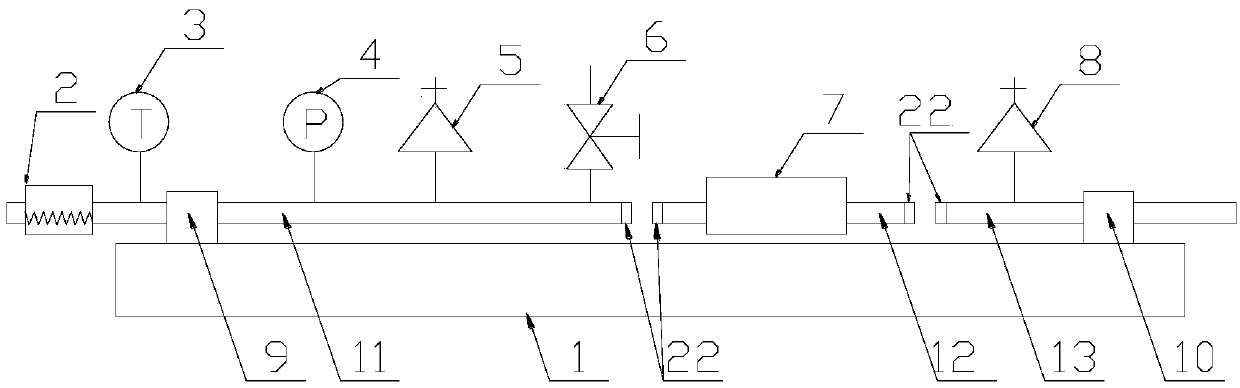

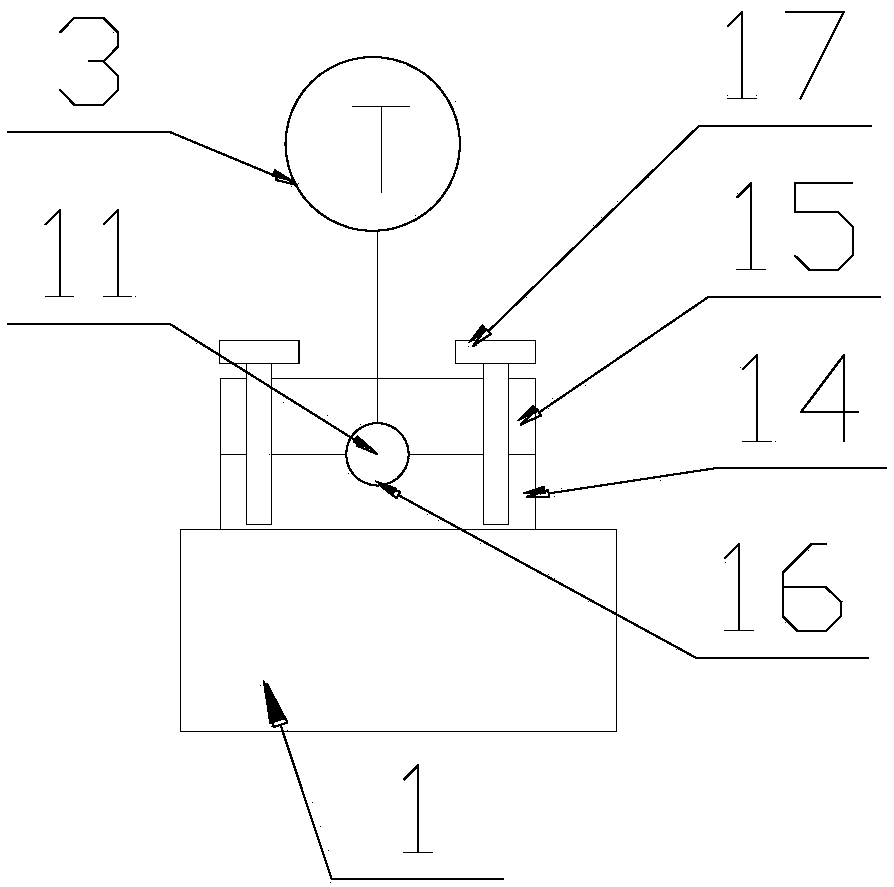

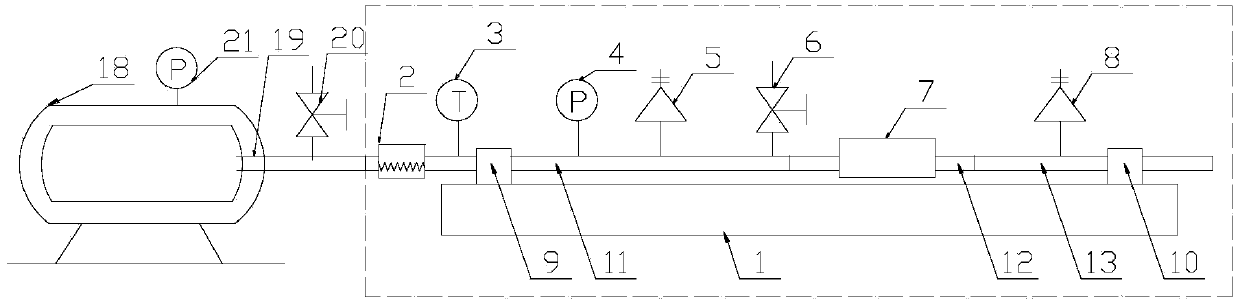

[0036] like Figure 1-2 As shown, a kind of vehicle LNG cylinder static evaporation rate pressure-holding test device provided by the present invention comprises a base 1, a test tube is arranged on the base 1, the front end of the test tube is connected with the vent pipe 19 of the checked bottle 18, and the rear The end of the test tube is connected with the gas recovery pipeline. The test tube is equipped with a temperature riser 2, a thermometer 3, a pressure gauge 4, a flow meter 7, and a micro-opening safety valve 8. There are pressure gauges 4 and 7 flow meters on the test tube. Equipped with a fully opened safety valve 5 and a vent stop valve 6 .

[0037]The test tube includes a first metal tube 11, a second metal tube 12, and a third metal tube 13 from front to back. The front and rear ends of the second metal tube 12 are detachable from the first metal tube 11 and the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com