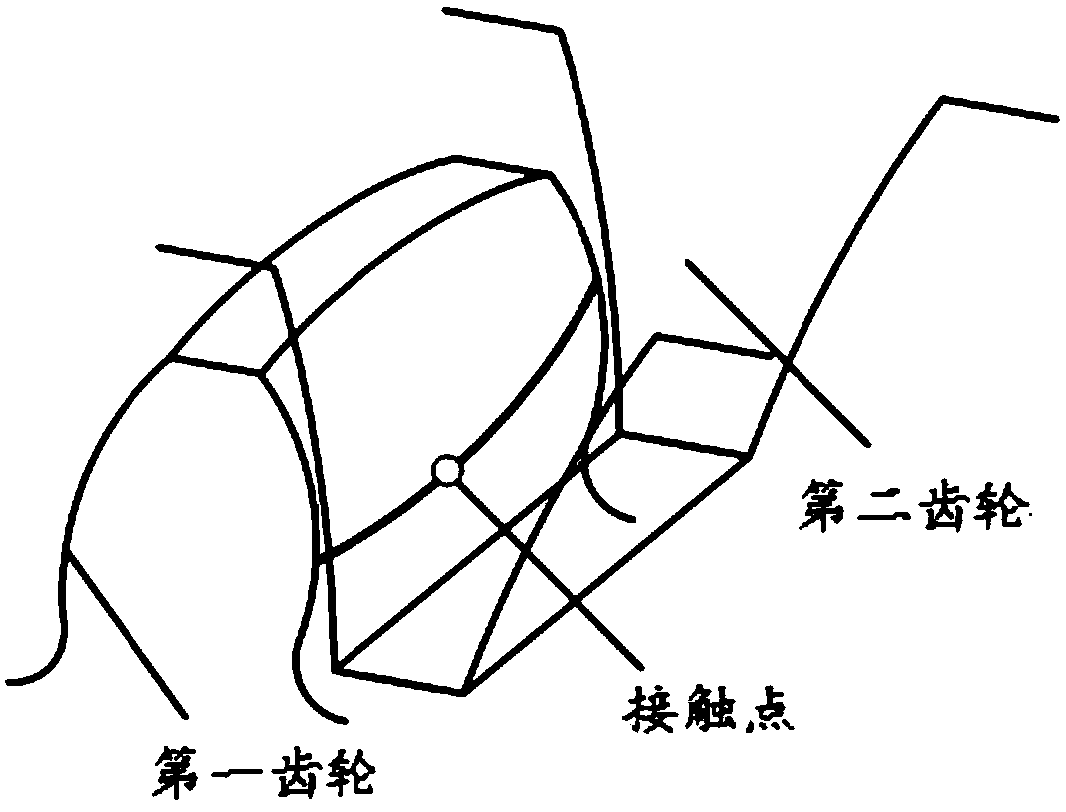

Opposite-configuration gear meshing pair based on line-plane conjugation and a design method thereof

A design method and conjugate gear technology, applied in gear transmission, design optimization/simulation, belt/chain/gear, etc., can solve the problem of unresolved gear axis, unresolved gear axis deviation and pitch error, deviation pitch error, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

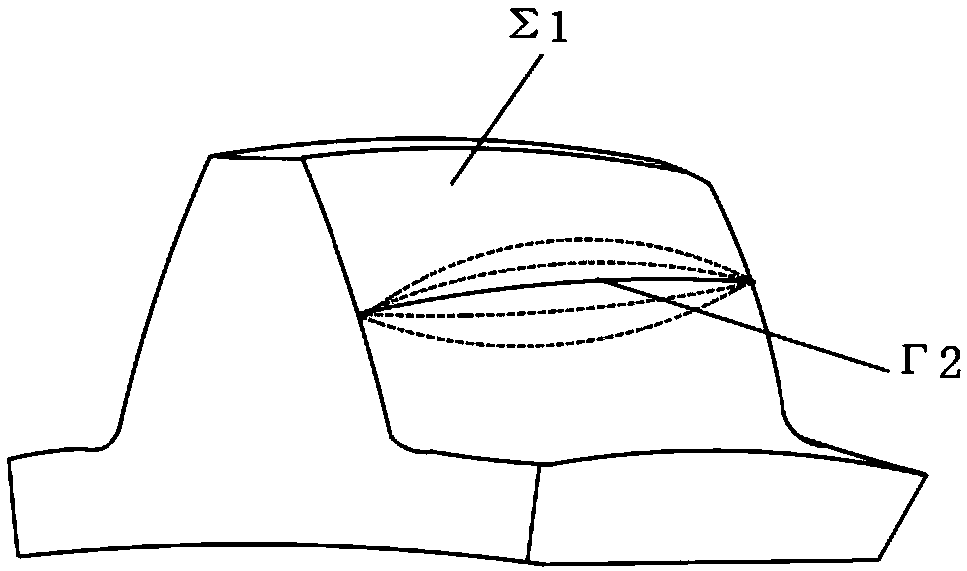

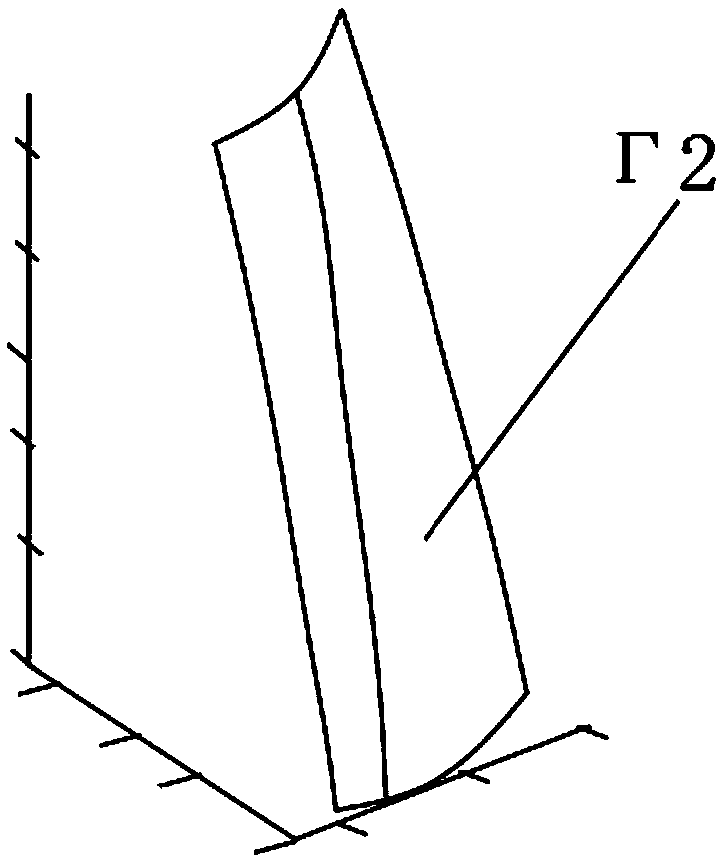

[0067] The present invention provides a method for designing a paired gear meshing pair based on line-plane conjugation. The design method for a paired gear meshing pair based on line-plane conjugate includes the following steps: i) determining the curved surface Σ of the first gear 1 The equation is: Among them, u, v are surface parameters; ii) determine the contact trace on the tooth surface of the first gear The equation is: where φ is a spatial parameter; iii) determine the normal vector of the contact trace on the tooth surface of the first gear (n x2 , n y2 , n z2 )for: iv) by the formula n·v (12) =0, determine the curve and surface ∑ 1 The meshing equation of ; v) according to the contact trace In a fixed coordinate system S 1 The following equation and the meshing equation determine the conjugate curve; vi) According to the conjugate curve, determine the second gear tooth surface Σ 2 equation.

[0068] The present invention takes the internal meshi...

Embodiment 2

[0148] The difference between this embodiment and the first embodiment is that in step vi, the envelope method is used to determine the tooth profile equation of the gear.

[0149] Specifically, as Figure 13 As shown, assume that the gear 2 is fixed, and the instantaneous center line I is purely rolled on the instantaneous center line Π, and the tooth shape 1 forms a curve family on the plane of the gear 2. Since tooth shape 2 and tooth shape 1 are in tangential contact at every instant, mathematically speaking, tooth shape 2 should be the envelope of the curve family formed by tooth shape 1. Using this principle, the tooth shape 2 can be obtained from the motion law of the gear pair and the tooth shape 1. This method is called the envelope method.

[0150] The tooth shape of another gear is enveloped by the tooth shape of one gear. This phenomenon can be clearly observed when the gear is processed by the generating method. For example, the tooth shape of the gear shaping cu...

Embodiment 3

[0152] The difference between this embodiment and the first embodiment is that step vi adopts the tooth profile normal method to determine the tooth profile equation of the gear.

[0153] Specifically, let the gears 1 and 2 both rotate, and at a certain moment, the tooth profile 1 is at Figure 14 The position shown by the solid line in the center, according to the condition of n·v=0, a point M can be obtained on the gear 1, and its normal line passes through the instantaneous center point P, then M is the contact point of the instantaneous tooth profile 1 and 2 . Gear 1 rotates through an angle, and the tooth profile turns to Figure 13 At the position shown by the dotted line in the middle, the point M' where the normal line passes through the point P can also be obtained, and then M' is the contact point of the instantaneous two tooth profiles. Using this method to obtain a series of contact point positions during the rotation of the gear 1, its trajectory in the fixed pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com