Hydrofining catalyst performance prediction method

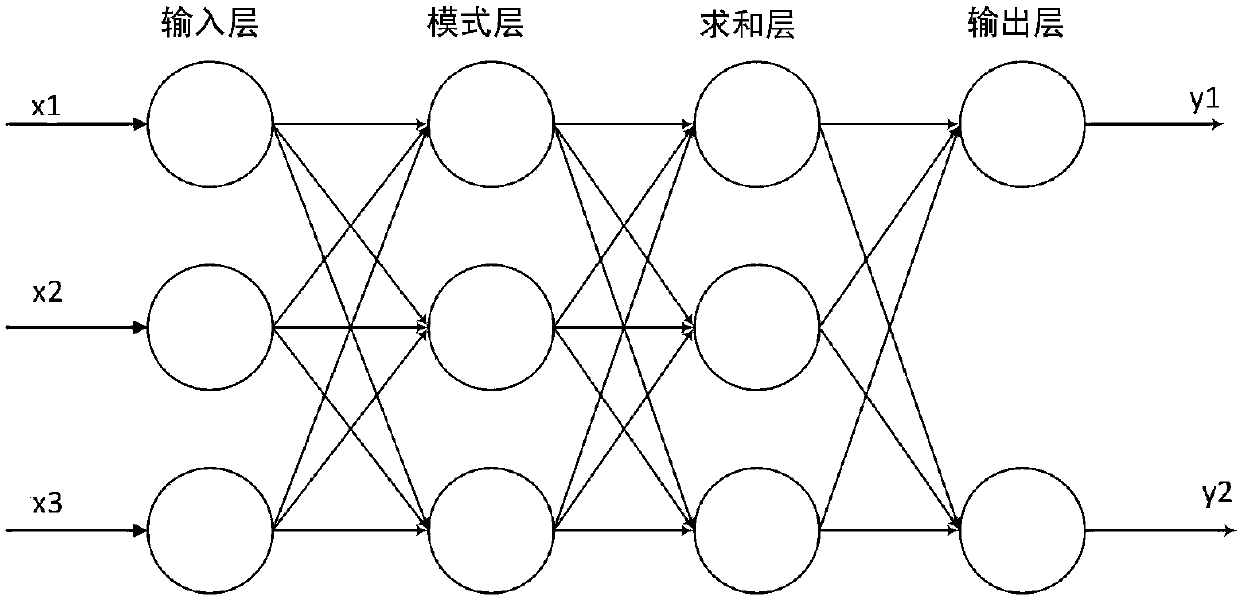

A technology for hydrorefining and performance prediction, applied in chemical property prediction, neural learning method, chemical statistics and other directions, can solve problems such as affecting the economic benefits of enterprises, waste of manpower and material resources, long operation cycle, etc., to save research and development costs, predicting The effect of high precision and strong generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

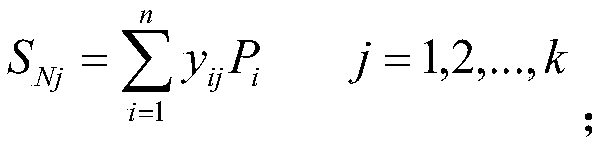

Method used

Image

Examples

Embodiment 1

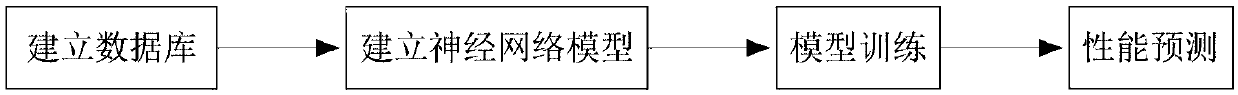

[0033] Hydrotreating catalyst performance prediction method, the process is as follows figure 1 shown, including the following steps:

[0034] 1) Hydrofining catalyst preparation

[0035] Fully mix 100g of pseudo-boehmite powder, 3ml of nitric acid, 3g of safflower powder, and 100ml of pure water, and knead them into shape through a twin-screw extruder. After calcination at a high temperature of ℃, the hydrorefining catalyst carrier is prepared. The basic nickel carbonate solid is prepared into a saturated solution, the content in terms of oxides is 20.0wt%, the hydrogenation refining catalyst carrier and the basic nickel carbonate solution are fully mixed, and the hydrogenated Refined catalyst;

[0036] 2) Performance evaluation of hydrofining catalyst

[0037] Install the hydrorefining catalyst in the hydrogenation microreactor, select the reaction pressure to be 1.6MPa, the reaction temperature to be 240°C, the hydrogen-to-oil ratio to be 100, and the volume space veloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com