Sheet manufacturing device and method for controlling sheet manufacturing device

A technology for manufacturing devices and sheets, used in chemical instruments and methods, papermaking, papermaking machines, etc., and can solve problems such as difficulty in miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, preferred embodiments of the present invention will be described in detail using the drawings. In addition, the embodiment described below does not limit the content of the present invention described in the scope of the claims. In addition, not all the configurations described below are necessarily essential components of the present invention.

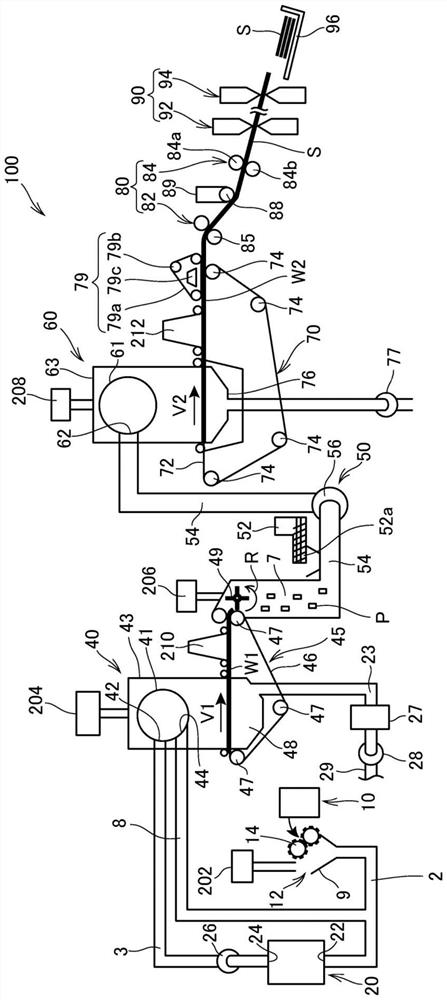

[0050] figure 1 It is a schematic diagram showing the configuration of the sheet manufacturing apparatus according to the embodiment.

[0051] The sheet manufacturing apparatus 100 described in this embodiment is, for example, dry-type used waste paper, such as confidential paper, which is used as a raw material, to fibrillate, pressurize, heat, and cut to manufacture new paper sheets. Optimal installation of paper. It is also possible to improve the bonding strength or whiteness of paper products by mixing various additives into the fibrous raw materials and combine them with uses, or to add functions such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com