Coffee milk beverage and preparation method thereof

A coffee milk beverage and coffee technology, which is applied to dairy products, processing roasted coffee, milk preparations, etc., can solve the problem of no dense milk foam and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

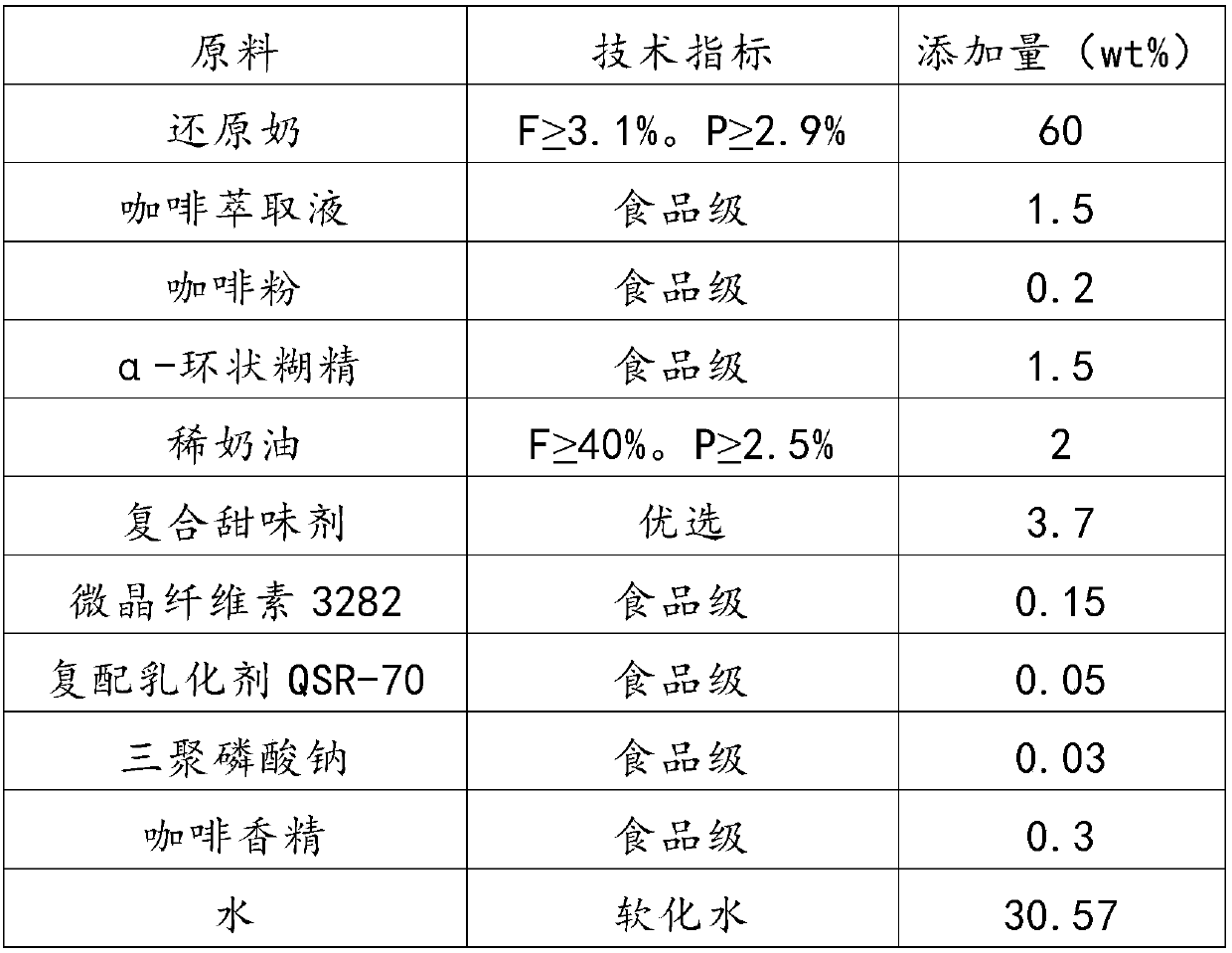

[0059] 1. Raw material formula:

[0060] raw material

Technical index

Addition amount (wt%)

F≥3.1%. P≥2.9%

50

Coffee extract

2

1

Cream

F≥40%. P≥2.5%

5

White sugar

Gifted class

3

Gellan Gum BD-001

0.05

Emulsifier QSR-70

Food grade

0.1

Sodium citrate

Food grade

0.03

water

38.82

total

100

[0061] Preparation Process:

[0062] Heat the raw milk to 75°C, add emulsifier QSR-70, gellan gum BD-001, white sugar and cream, and mix well to obtain liquid A;

[0063] The coffee extract was mixed with water at 85°C, sodium citrate was added, and the pH was adjusted to 6.7 to obtain feed liquid B; the amount of water added in feed liquid B was 15.5wt%;

[0064] α-Cyclodextrin was added to water and mixed uniformly to obtain feed liquid C; the amount of water added in feed liquid C was 23.32wt%;

[0065] After mixing material liquid A, material liquid B, and material liquid C, perform standardization of...

Embodiment 2

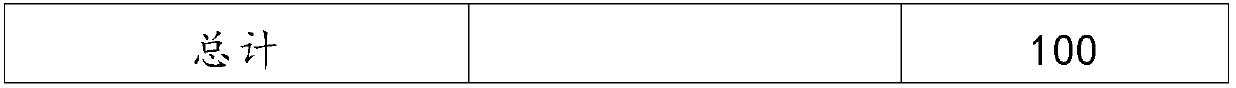

[0069] 1. Raw material formula:

[0070] raw material

Technical index

Addition amount (wt%)

F≥3.1%. P≥2.9%

80

coffee powder

Food grade

0.1

Food grade

0.5

Cream

F≥40%. P≥2.5%

0.01

White sugar

Gifted class

3

Microcrystalline Cellulose 3282

Food grade

0.3

Compound emulsifier SR-16

Food grade

0.2

Food grade

0.01

Food grade

0.06

water

15.82

total

100

[0071] Preparation Process:

[0072] The raw milk is heated to 70°C, and the compound emulsifier SR-16, microcrystalline cellulose 3282, white sugar and cream are added, and after mixing uniformly, liquid A is obtained;

[0073] The coffee extract is mixed with water at 75°C, sodium bicarbonate is added, and the pH is adjusted to 8.0 to obtain feed liquid B; the amount of water added in feed liquid B is 6.3wt%;

[0074] α-Cyclodextrin was added to water and mixed uniformly to obtain feed liquid C; the amount of water added in feed liquid C wa...

Embodiment 3

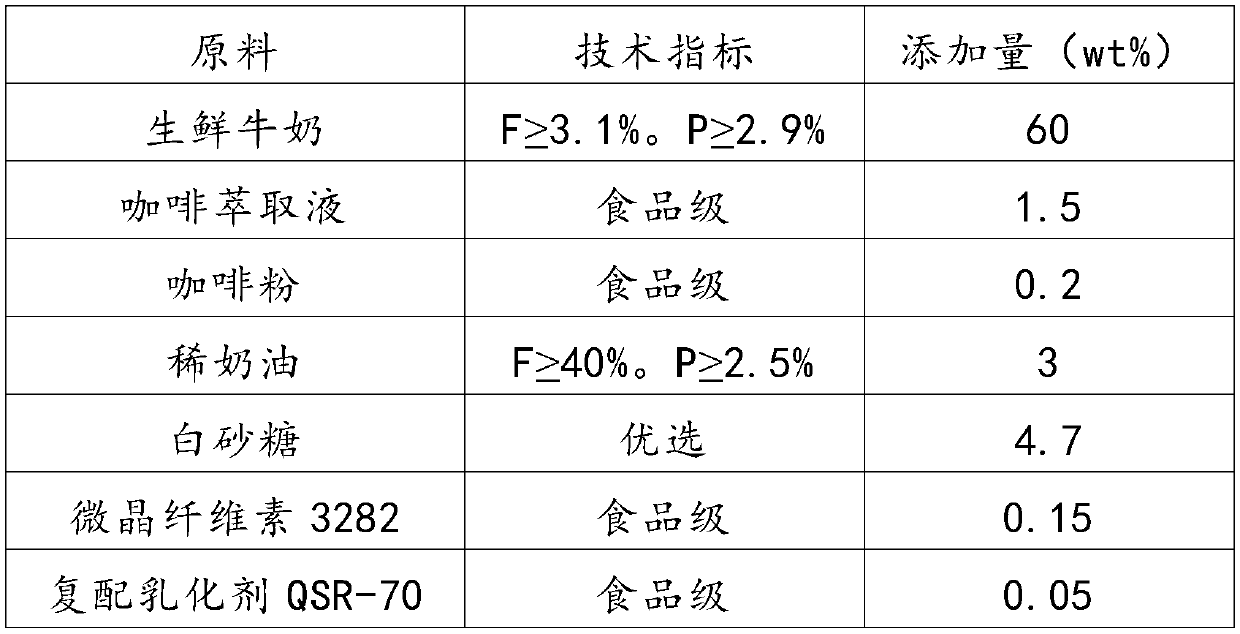

[0079] Ingredients formula:

[0080] raw material

Technical index

Addition amount (wt%)

F≥3.1%. P≥2.9%

30

Coffee extract

Food grade

2.5

α-Cyclodextrin

Food grade

2

Cream

F≥40%. P≥2.5%

1

White sugar

Gifted class

4.5

Compound stabilizer 9395

Food grade

0.15

Compound emulsifier QSR-70

Food grade

0.05

Sodium citrate

Food grade

0.07

Milk flavor

Food grade

0.03

Food grade

0.05

water

59.65

total

100

[0081] Preparation Process:

[0082] Heat raw milk to 90°C, add compound emulsifier QSR-70, compound stabilizer 9395, white sugar and cream, and mix well to obtain liquid A;

[0083] The coffee extract is mixed with 100°C water and sodium citrate is added. Adjust the pH to 7.0 to obtain feed liquid B; the amount of water added in feed liquid B is 17.9wt%;

[0084] α-Cyclodextrin was added to water and mixed uniformly to obtain feed liquid C; the amount of water added in feed liquid C was 41.75wt%;

[0085] After mixing materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com