A device, method and application for synthesizing drug-loaded metal organic framework materials based on microfluidic one-pot method

A metal-organic framework and microfluidic technology, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulations, can solve the problems of low drug loading efficiency and poor release of drug molecules, etc. Achieve high drug loading efficiency, ideal dissolution efficiency, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

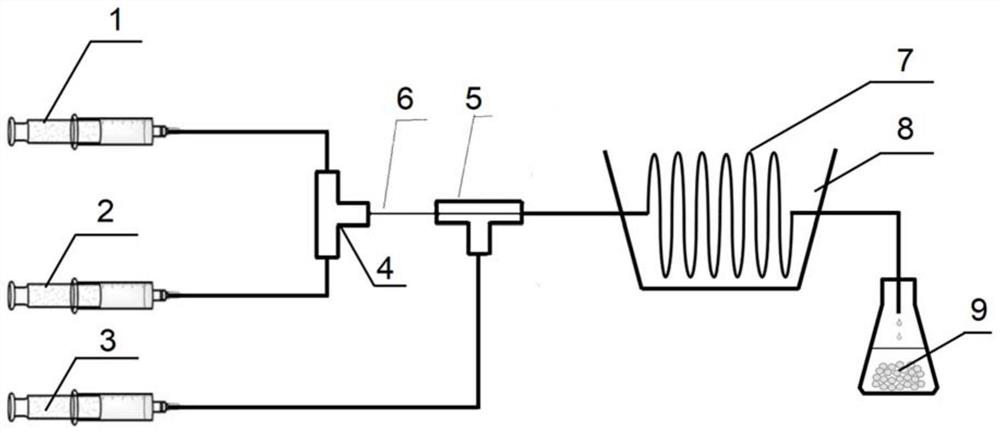

[0036] A device for synthesizing a drug metal organic skeleton material based on a microfluidic aperator, including syringe A 1, syringe B 2, syringe C 3, T-type connector A 4, T-connector B 5, stainless steel Capillary 6, PTFE capillary 7, constant temperature water bath 8 and collecting tanks 9. The syringe A 1, the syringe B 2 and the syringe C 3 is a normal medical syringe, a specification of 10 mL. The T-type connector A 4 and T-type connector B 5 respectively include two inlet ends and an outlet end, the syringe A 1 and the syringe B 2, respectively, respectively, two inlet terminal pipes of the T-connector A 4, respectively. . The stainless steel capillary 6 has an inner diameter of 0.1 mm, and the outlet end of the T-type connector A 4 is connected to one end of the stainless steel capillary 6. The other end of the stainless steel capillary 6 passes through an inlet end and the outlet end of the T-type connector B 5, and the inlet end of the stainless steel capillary 6 is ...

Embodiment 2

[0042] A device for synthesizing a drug metal organic skeleton material based on a microfluidic aperator, including syringe A 1, syringe B 2, syringe C 3, T-type connector A 4, T-connector B 5, stainless steel Capillary 6, PTFE capillary 7, constant temperature water bath 8 and collecting tanks 9. The syringe A 1, the syringe B 2 and the syringe C 3 is a normal medical syringe with a specification of 50 mL. The T-type connector A 4 and T-type connector B 5 respectively include two inlet ends and an outlet end, the syringe A 1 and the syringe B 2, respectively, respectively, two inlet terminal pipes of the T-connector A 4, respectively. . The stainless steel capillary 6 has an inner diameter of 0.3 mm, and the outlet end of the T-type connector A 4 is connected to one end of the stainless steel capillary 6. The other end of the stainless steel capillary 6 passes through an inlet end and the outlet end of the T-type connector B 5, and the inlet end of the stainless steel capillary 6...

Embodiment 3

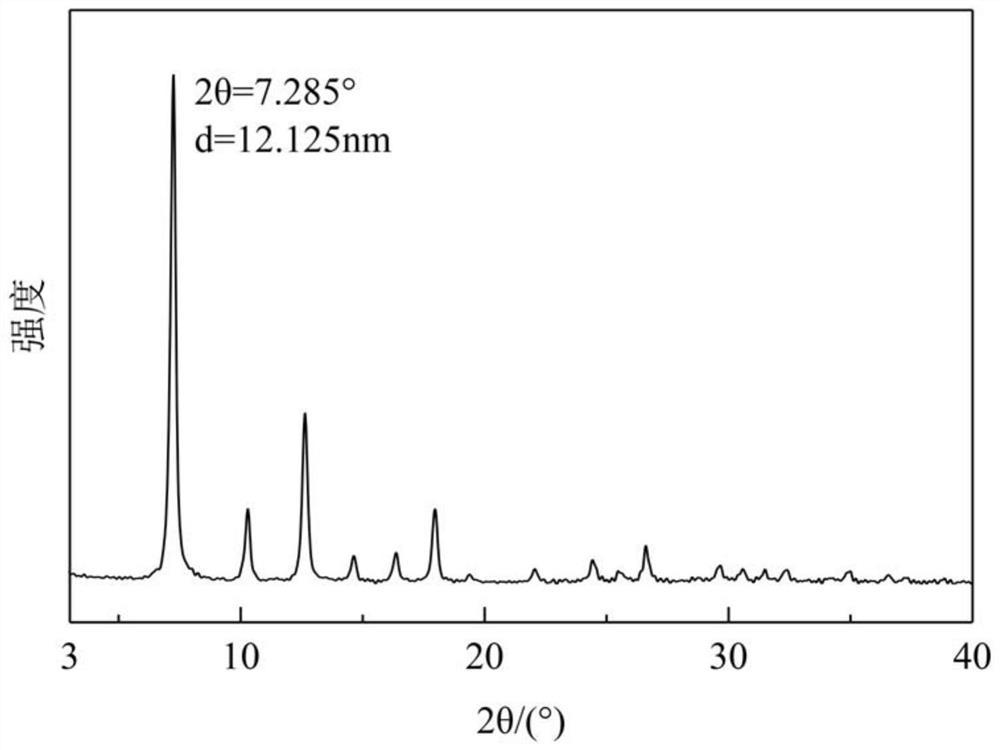

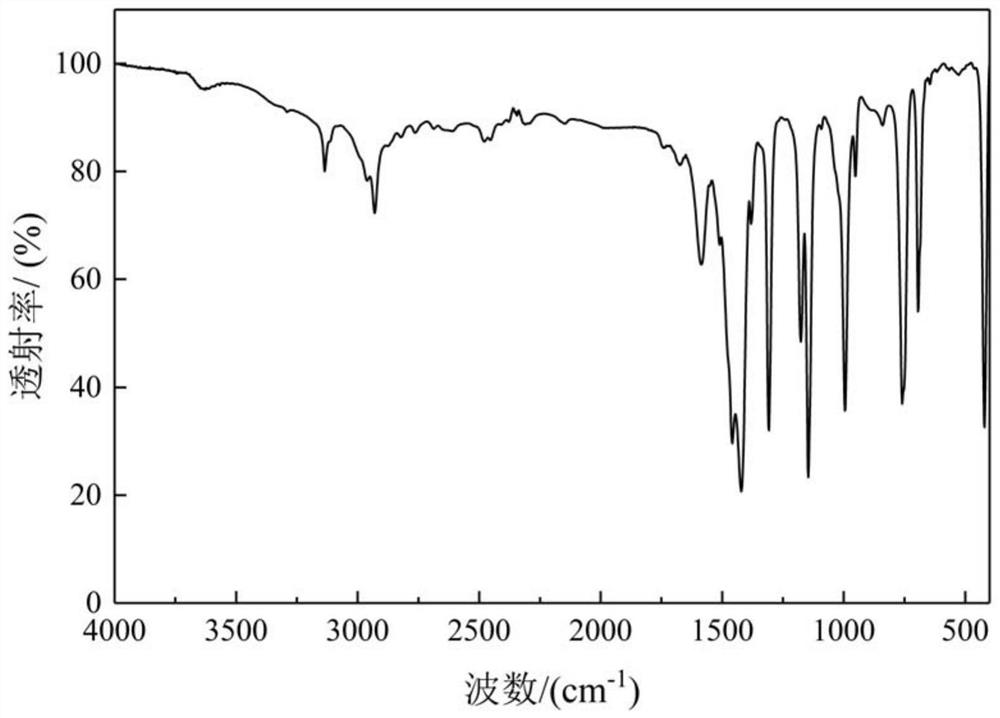

[0049] The method of synthesizing metal organic skeleton material ZIF-8 empty shell material based on Example 2, the specific steps are as follows:

[0050] Building a device, ready to carry out: 0.1 mmol Zn (NO 3 ) 2 · 6h 2 O Soluble in 10 ml deionized water, transfer to syringe A 1; weigh 0.8 mmol 2-methylimidazole in 10 ml deionized water, transfer to syringe B 2; quantity to take a grade soybean oil 50 ml transfer to Syringe C 3.

[0051] Synthesis of ZIF-8 carrier empty shells in microfluidic control: At the same time, open the injection pump connected to the syringe A 1 and syringe B 2, set the flow rate of 25 μL / min, drive the inner phase pressurization through the T-type connector A 4 After mixing, the stainless steel capillary 6 flows, and after the inner phase press is stabilized, the injection pump connected to the syringe C 3 is turned on, and the flow rate is 100 μl / min, and the driving outer phase carrier flows into the T-connector B 5 flow. The inner phase react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com