A cc-hbdp treatment process for livestock and poultry breeding wastewater

A technology for livestock and poultry breeding wastewater and treatment process, which is applied in animal husbandry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problem of influent COD not being too high, achieve less sludge production, and reduce organic load , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

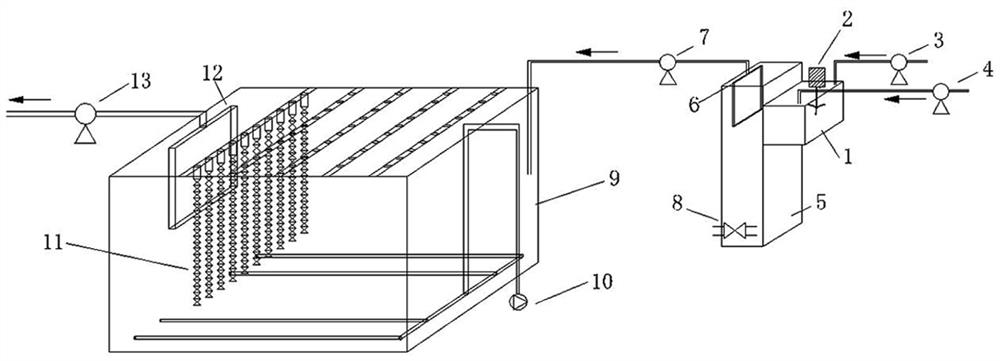

[0027] Example 1: In step (1), the coagulant in the coagulation tank is polyaluminum chloride, the dosage is 50 mg / L, the stirring speed is 50 r / min, and the residence time is 5 min; by controlling the dosage of the coagulant , so that the C / N ratio of the sewage entering the mixed denitrification tank is 1:1.

[0028] In this embodiment, in step (2), the hydraulic retention time in the clarifier is 1h, and the aperture of the first solid-liquid separation device is 25 μm; the captured carbon source is discharged through the vent valve 8 below the clarifier 5 for collection.

[0029] In this embodiment, in step (3), the dissolved oxygen in the mixed denitrification tank is controlled at 0.2 mg / L and the pH is controlled at 7.8 by controlling the aeration amount of the aeration device 10; the braided belt is vertically suspended in the mixed denitrification tank The density of the braided packing 11 is 50 pieces per square meter.

Embodiment 2

[0030] Example 2: In step (1), the coagulant in the coagulation tank is polyaluminum chloride, the dosage is 400 mg / L, the stirring speed is 300 r / min, and the residence time is 20 min; by controlling the dosage of the coagulant , so that the C / N ratio of the sewage entering the mixed denitrification tank is 3:1.

[0031] In this embodiment, in step (2), the hydraulic retention time in the clarifier is 3 h, and the aperture of the first solid-liquid separation device is 150 μm; the captured carbon source is discharged through the vent valve 8 below the clarifier 5 for collection.

[0032] In this embodiment, in step (3), the dissolved oxygen in the mixed denitrification tank is controlled at 0.5 mg / L and the pH is controlled at 8.2 by controlling the aeration amount of the aeration device 10; the braided belt is vertically suspended in the mixed denitrification tank The density of the braided packing 11 is 100 pieces per square meter.

Embodiment 3

[0033] Example 3: In step (1), the coagulant in the coagulation tank is polyaluminum chloride, the dosage is 200 mg / L, the stirring speed is 300 r / min, and the residence time is 5 min; The C / N ratio of the sewage entering the mixed denitrification tank is 2:1.

[0034] In this example, in step (2), the hydraulic retention time in the clarifier is 3 h, and the aperture of the first solid-liquid separation device is 70 μm; the captured carbon source is discharged through the vent valve 8 below the clarifier 5 for collection.

[0035]In this embodiment, in step (3), the dissolved oxygen in the mixed denitrification tank is controlled at 0.2 mg / L and the pH is controlled at 8.0 by controlling the aeration amount of the aeration device 10; the braided belt is vertically suspended in the mixed denitrification tank The density of the braided packing 11 is 70 pieces per square meter.

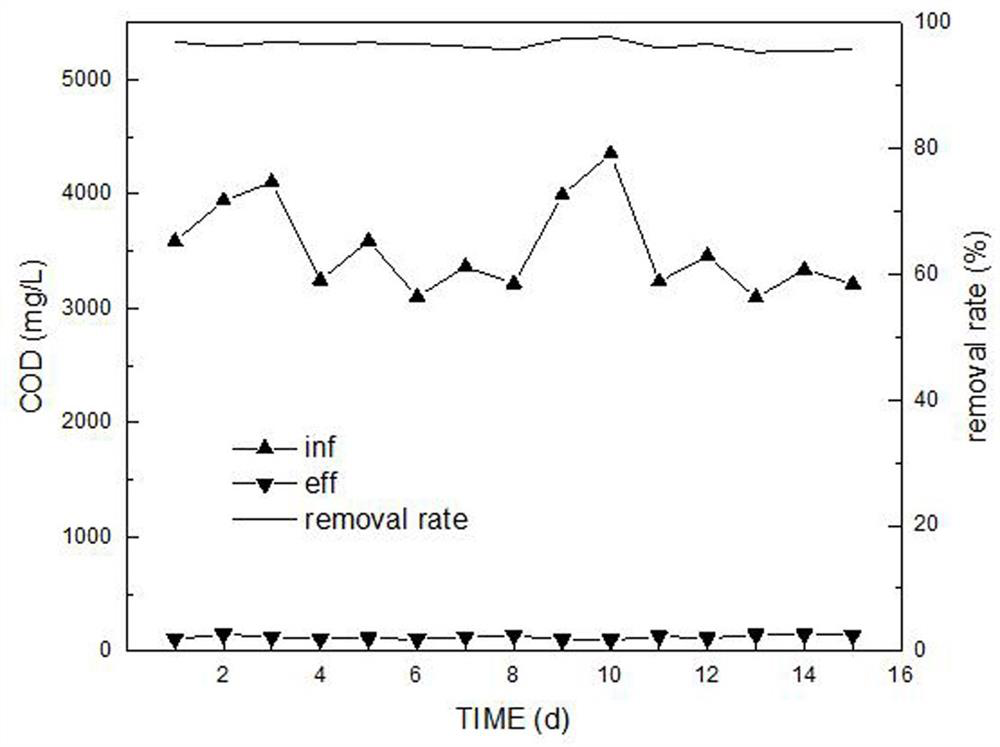

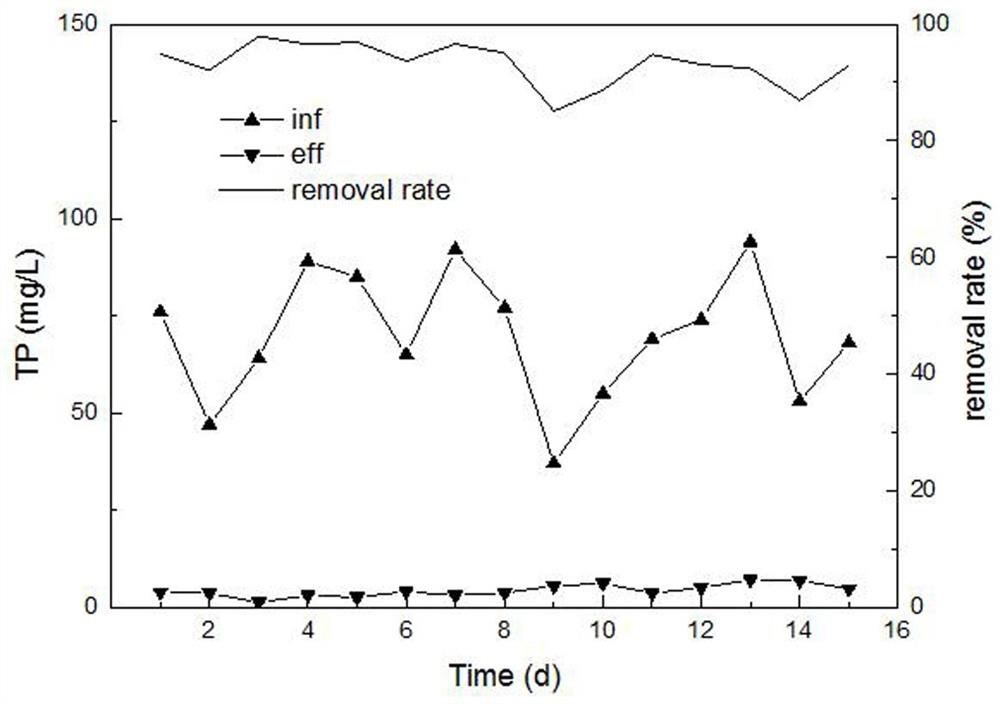

[0036] The influent COD concentration of livestock and poultry breeding wastewater in a rural area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com