Joint for thermal bubble micropump

A technology of micropump and hot bubble, which is applied in the direction of laboratory containers, laboratory utensils, chemical instruments and methods, etc., and can solve the problem of difficult connection of hot bubble micropump on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

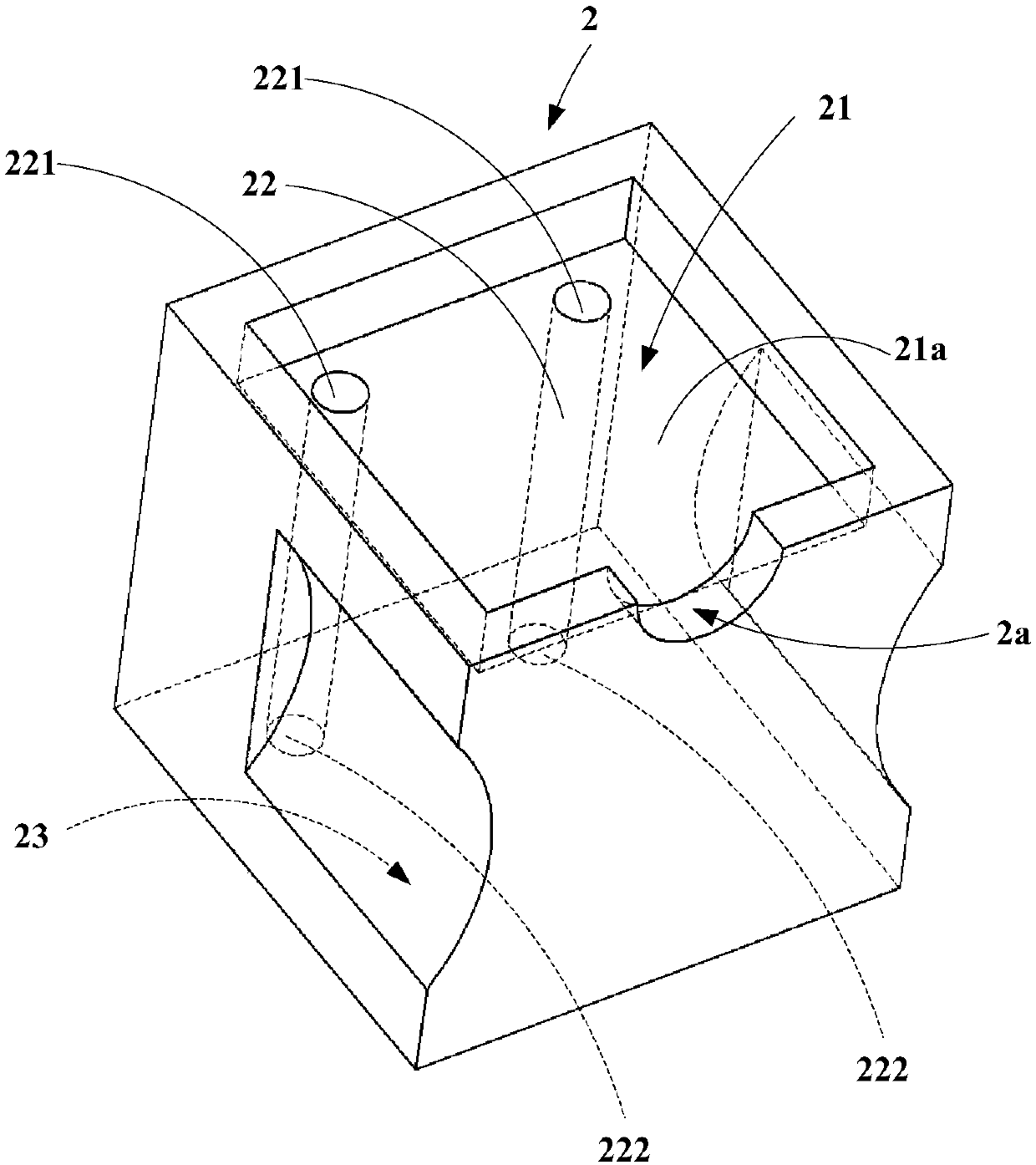

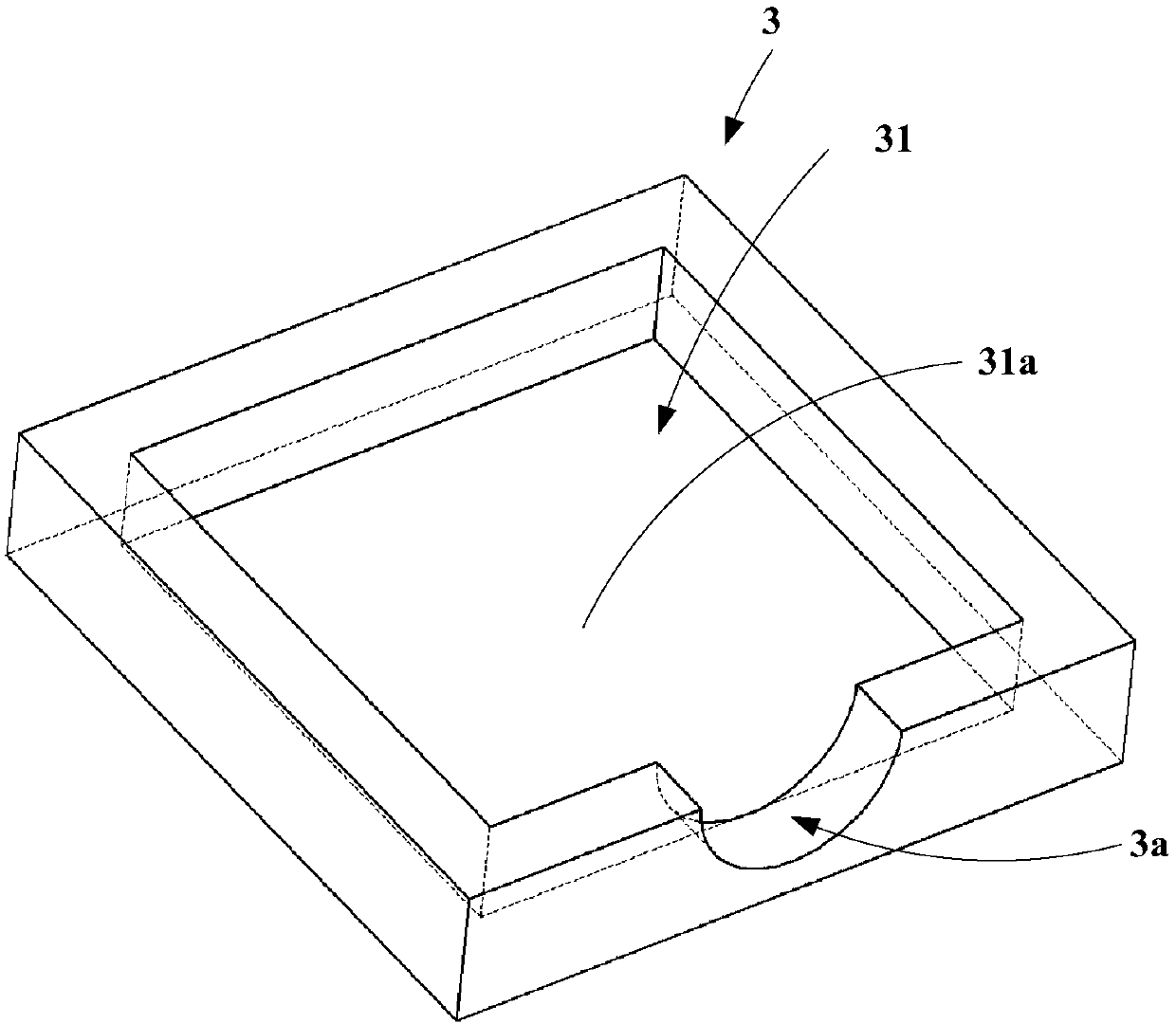

[0030] Embodiment 1 of the present application provides a joint for a heat bubble micropump, Figure 5 is an exploded schematic diagram of the components of the joint, such as Figure 5 As shown, the joint 5 may include: a gasket 2 , a top cover 3 and a connecting pipe 4 . Such as Figure 5 As shown, the thermal bubble micropump 1 can be arranged in the connection 5 .

[0031] figure 1 is a schematic diagram of the thermal bubble micropump, figure 2 is a schematic diagram of the gasket of this embodiment, image 3 is a schematic diagram of the top cover of this embodiment, Figure 4 is a schematic diagram of the connecting pipe of this embodiment.

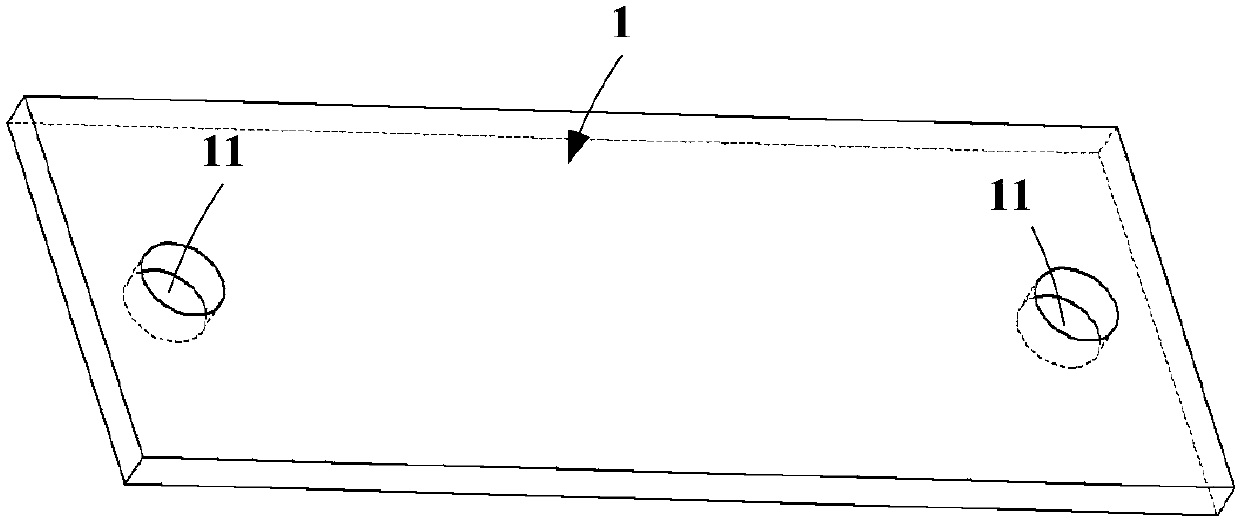

[0032] Such as figure 1 As shown, the thermal bubble micropump 1 can have a channel opening 11 through which liquid can flow into or out of the thermal bubble micropump 1 . The distance between the centers of the two flow channel openings 11 can have different specifications, such as 1.5mm, 2.5mm, 3.5mm, 4.5mm and so on. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com