Automatic loading and unloading device of laser cutter

A technology of automatic loading and unloading, laser cutting machine, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of lower plate follow, safety accidents, damage to equipment, etc., to reduce the dependence of labor costs, reduce labor Strength, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

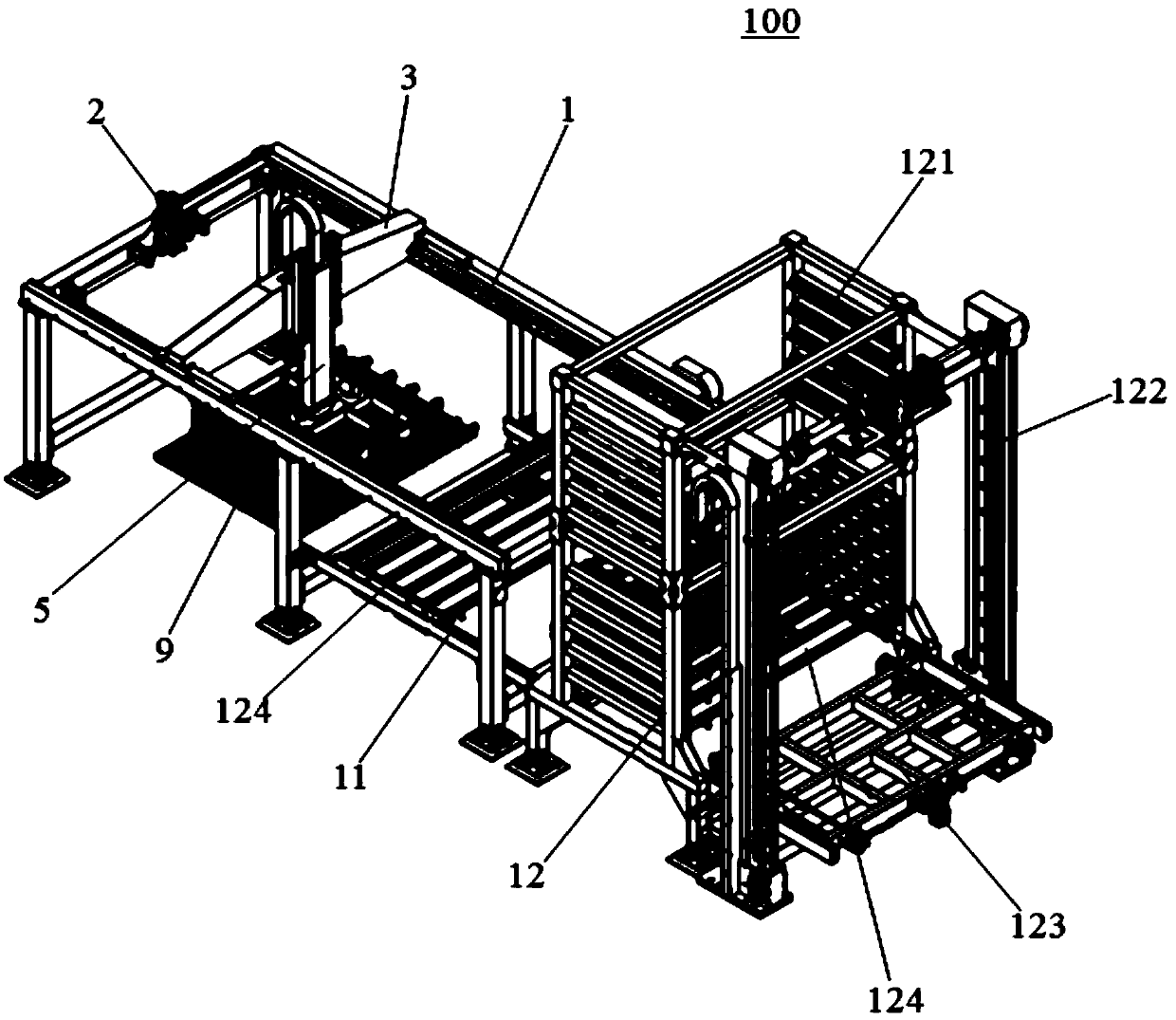

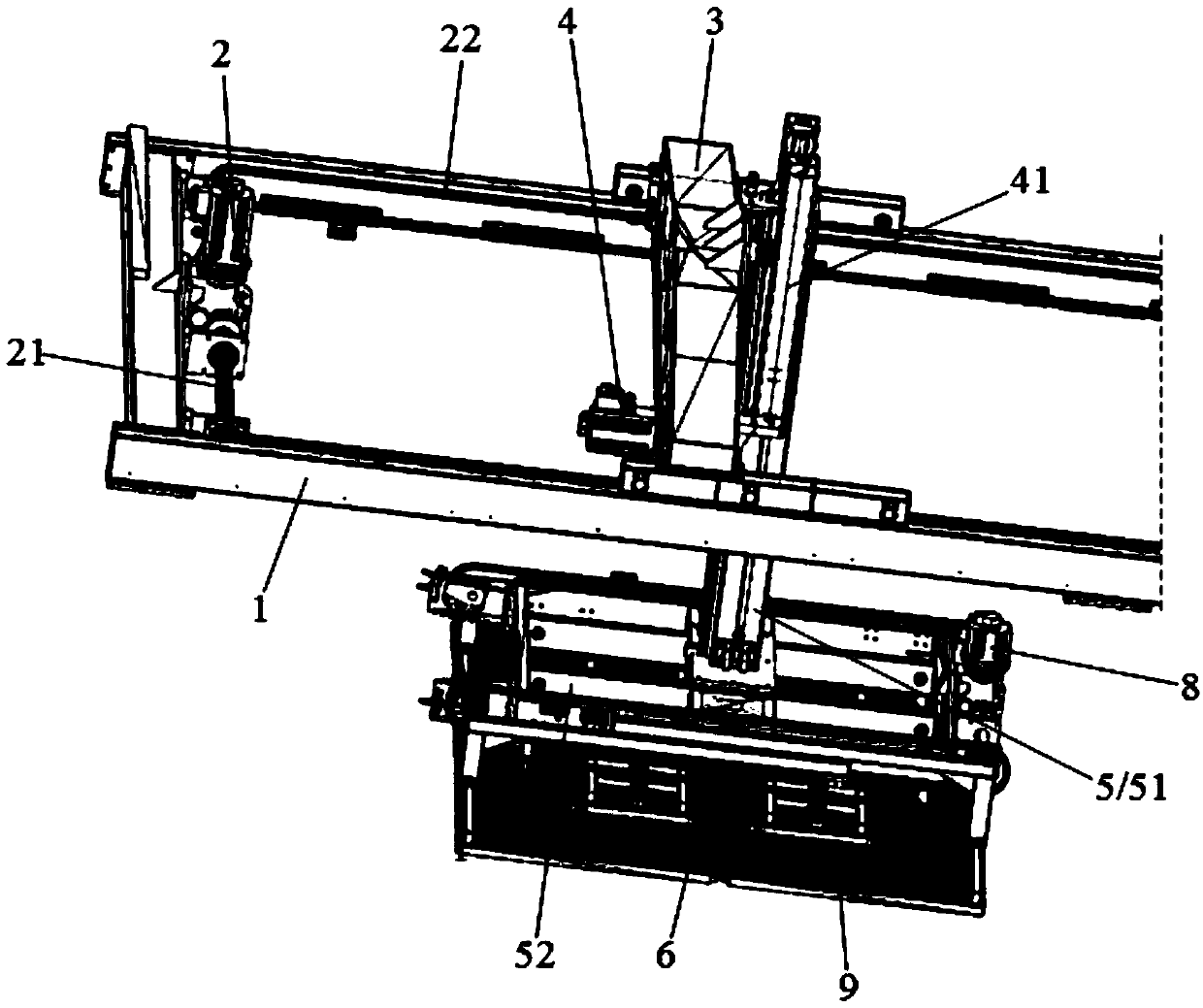

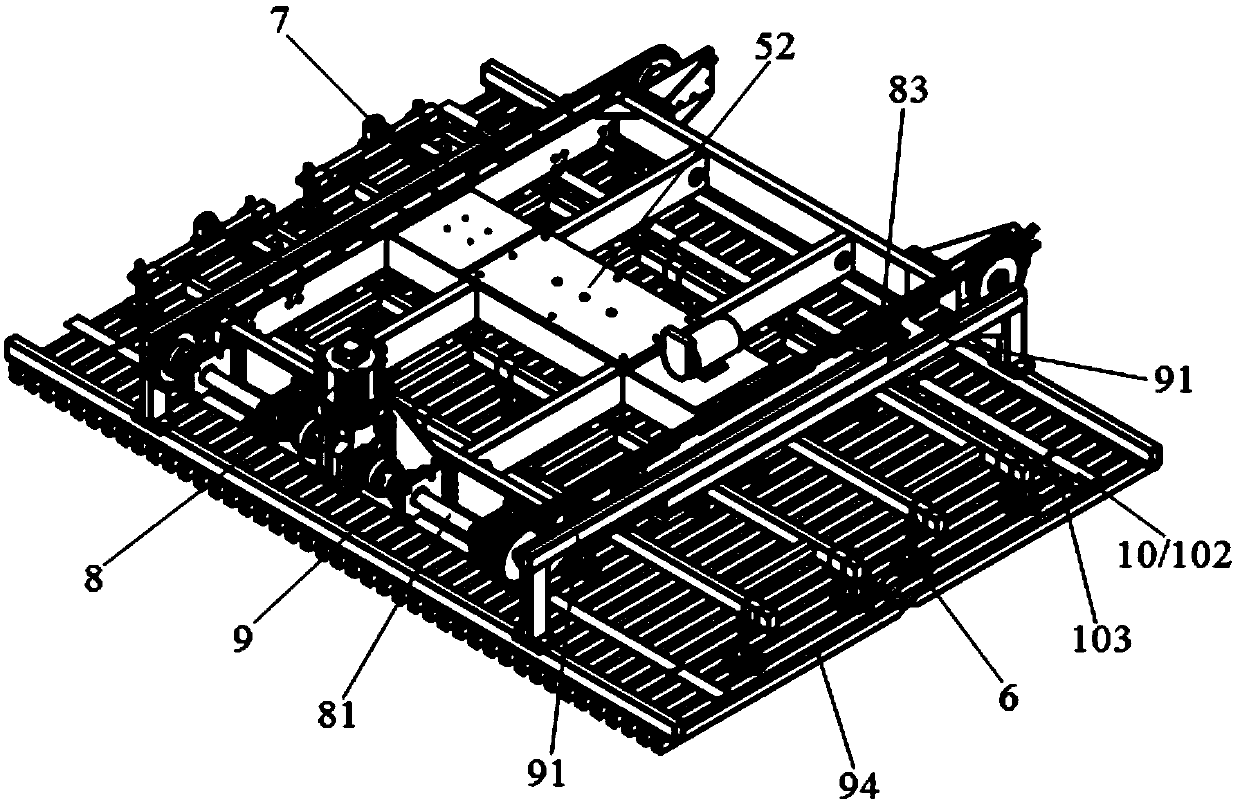

[0044] Please refer to Figure 1-Figure 15 , the present embodiment is an automatic loading and unloading device 100 for a laser cutting machine, which includes a transfer gantry steel frame 1, a horizontal transfer driver 2 fixed on the transfer gantry steel frame 1, and a horizontal transfer driver 2 driven The first support frame 3, the lifting driver 4 fixed on the first support frame 3, the second support frame 5 driven by the lifting driver 4 to move up and down, a number of suction nozzles 6 fixed below the second support frame 5, The disengagement mechanism 7 that is arranged at the outermost end of all the suction nozzles 6 and is used to disengage the uppermost plate and the lower plate, the claw driver 8 fixed on the second support frame 5, is driven by the claw driver 8 to move closer or closer A pair of claws 9 that are movable and located under all suction nozzles 6 .

[0045] The horizontal transfer driving part 2 is a servo motor, which is arranged at one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com