Magnetic press mounting positioning tool and using method thereof

A technology of positioning tooling and magnetic force, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of high technical level requirements of operators, difficult clamping, low qualification rate, etc., and improve the flatness defect rate. , The effect of reducing the difficulty of clamping and uniform distribution of suction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

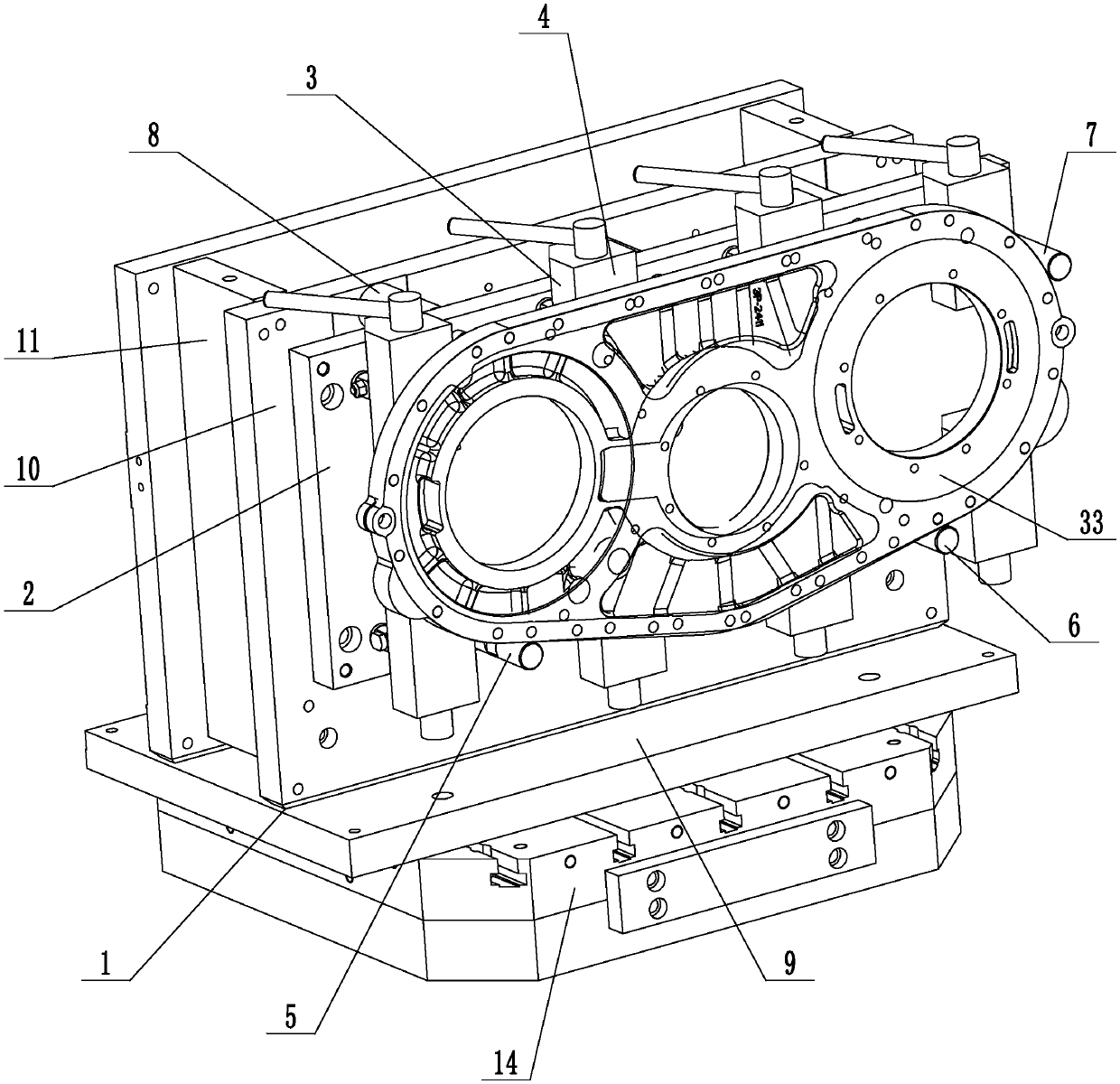

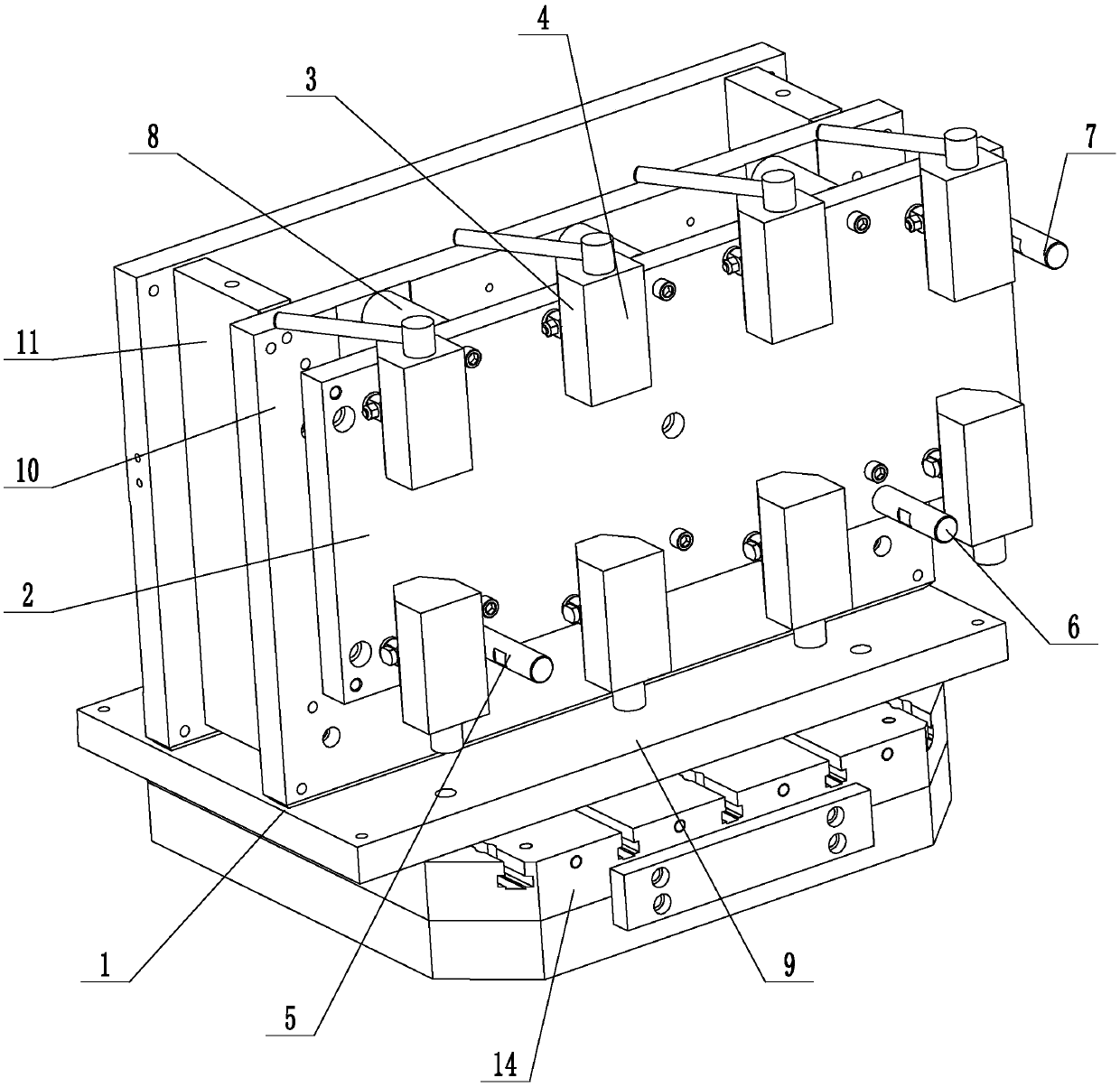

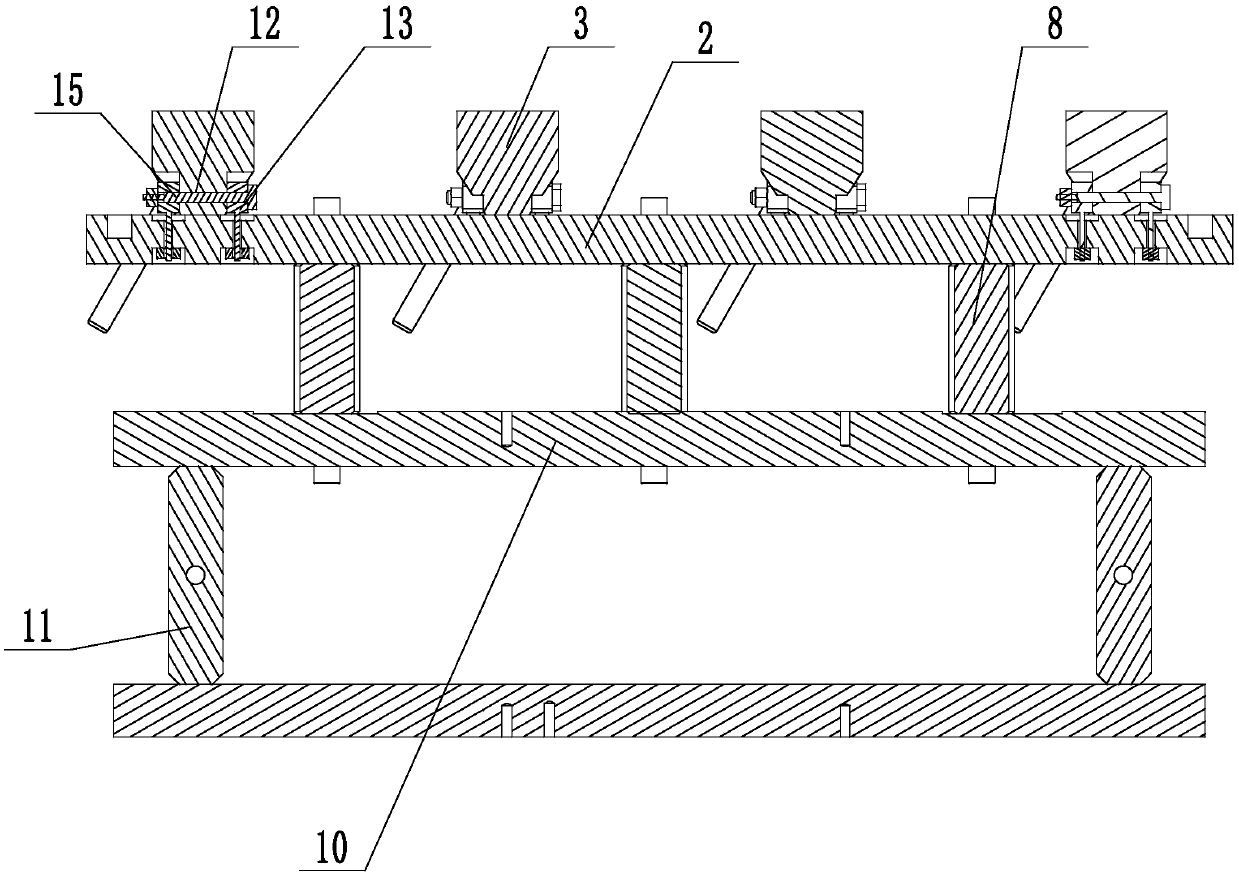

[0023] Embodiment 1: A magnetic press-fit positioning tool (see attached figure 1 To attach image 3 ), including a base 1, a bottom plate 2 vertically connected to the base, a number of electromagnetic blocks 3 are fastened on the bottom plate, and the surface of the electromagnetic block away from the bottom plate is a suction support surface 4 with a planar structure, and the bottom left positioning is installed on the bottom plate Column 5, lower right positioning column 6, upper right positioning column 7, the lower left positioning column is placed on the left side of the lower edge of the bottom plate, the lower right positioning column is placed on the right side of the lower edge of the bottom plate, and the upper right positioning column is placed on the upper right edge of the bottom plate , along the normal direction of the base plate, the lower left positioning column, the lower right positioning column, and the upper right positioning column are all higher than t...

Embodiment 2

[0025] Embodiment 2: A magnetic press-fit positioning tool (see attached Figure 4 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, a negative pressure groove 16 is provided on the suction support surface of the electromagnetic block, a sealing ring 17 is installed on the opening edge of the negative pressure groove, and a negative pressure groove is connected to the electromagnetic block. The negative pressure pipe 18 that pressure groove communicates with, the suction pump is installed on the base plate, and the negative pressure pipe is all connected with the suction pump. Other structures are the same as in Embodiment 1. When the electromagnetic block is attracted to the workpiece, the suction pump is started to pump air into the negative pressure tank, so that a negative pressure is formed in the negative pressure tank, thereby increasing the adsorption force of the suction support on the surface of the workpiece.

[00...

Embodiment 3

[0027] Embodiment 3: A magnetic press-fit positioning tool (see attached Figure 5 , attached Figure 6 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, a negative pressure groove 16 is provided on the suction support surface of the electromagnetic block, a sealing ring 17 is installed on the opening edge of the negative pressure groove, and a negative pressure groove is connected to the electromagnetic block. The negative pressure pipe 18 that pressure groove communicates with, the suction pump is installed on the base plate, and the negative pressure pipe is all connected with the suction pump. Other structures are the same as in Embodiment 1. When the electromagnetic block is attracted to the workpiece, the suction pump is started to pump air into the negative pressure tank, so that a negative pressure is formed in the negative pressure tank, thereby increasing the adsorption force of the suction support on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com