Jig structure

A side wall and arc angle technology, applied in the field of fixtures, can solve problems such as easy to wrinkle, difficult to shape, and unable to meet the design trend of four-sided curved glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

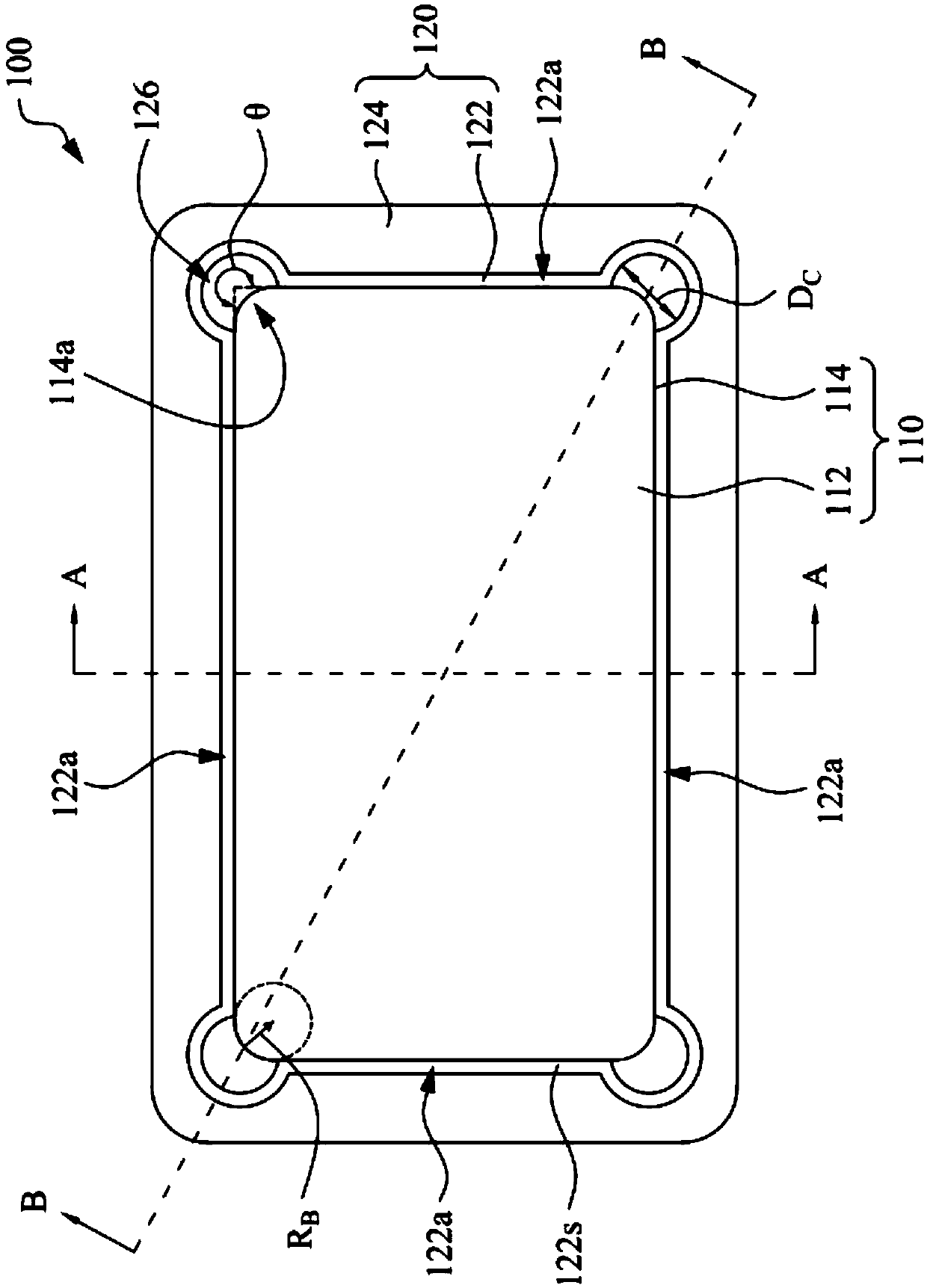

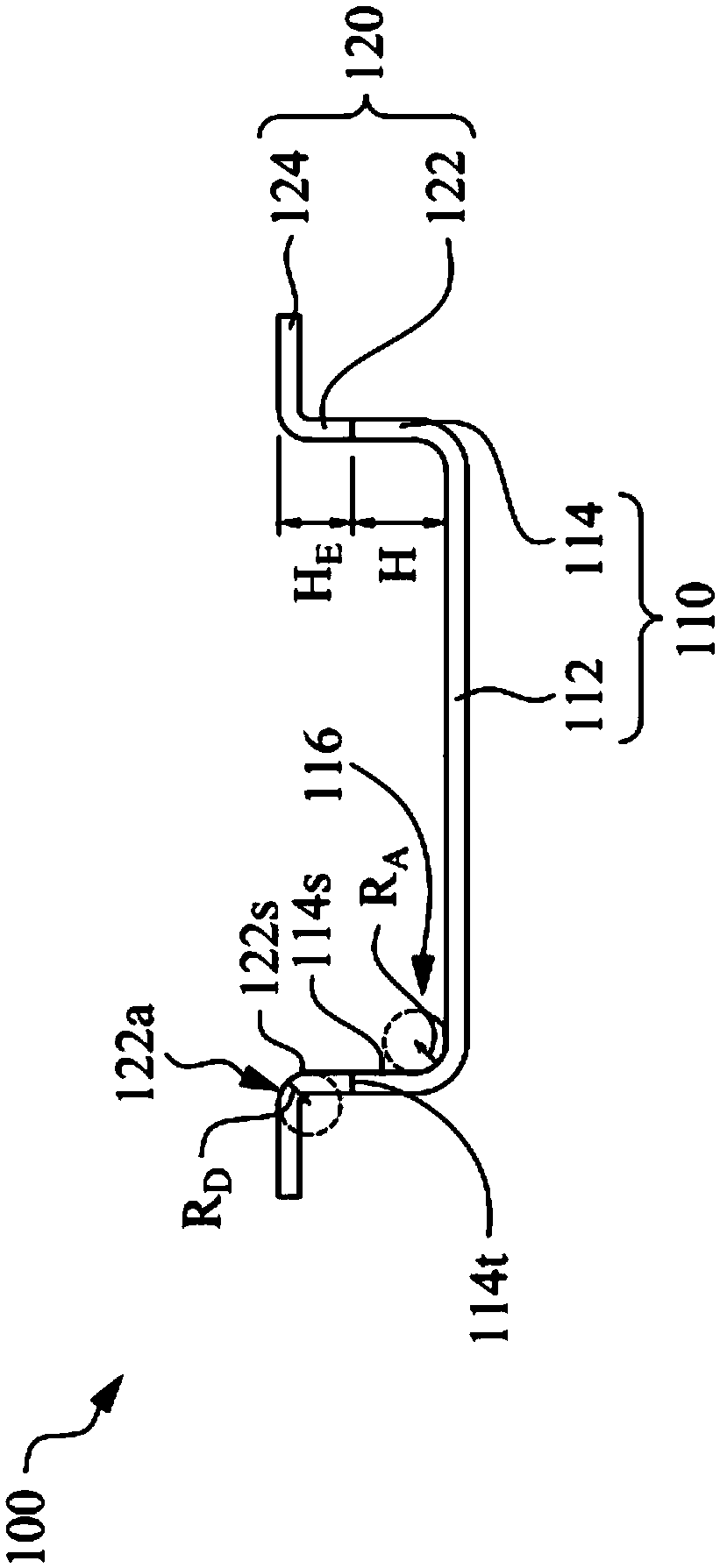

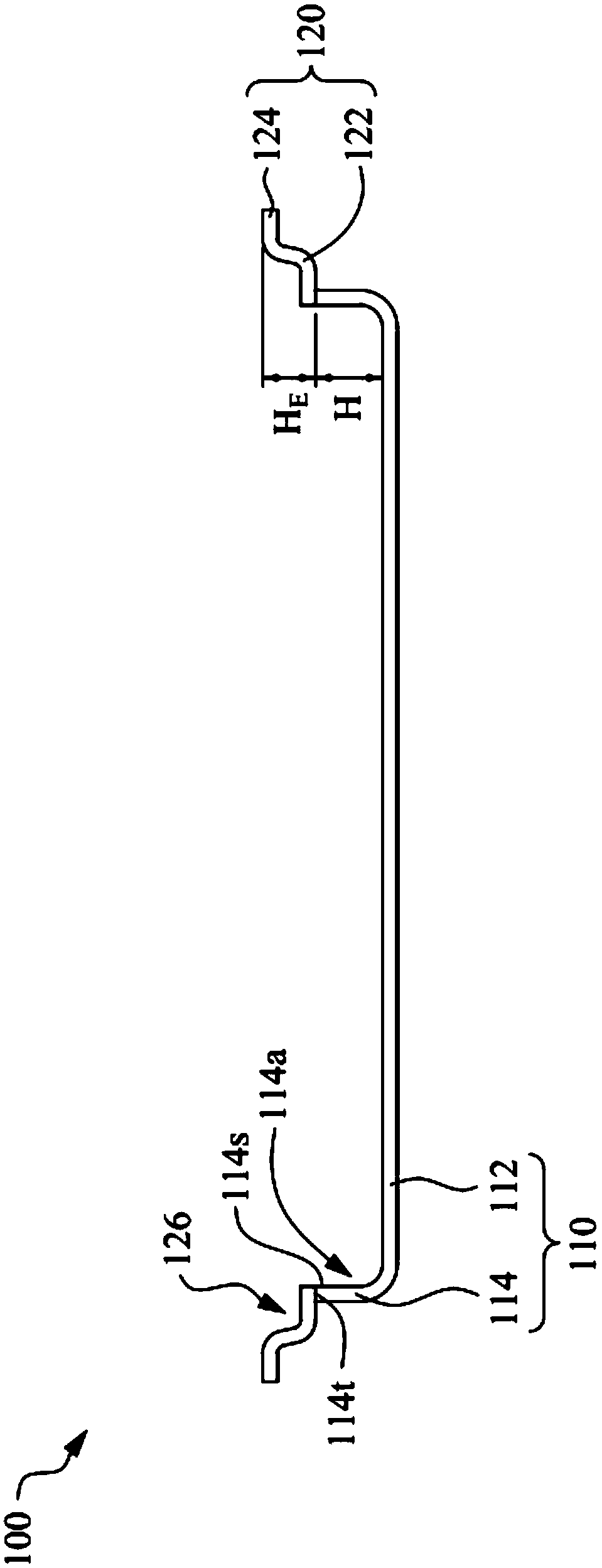

[0029] The jig structure 100 of this embodiment can be used for thermoforming a film, such as four-curved surface thermoforming.

[0030] For example, the film base material that can be used for thermoforming processing can be a material with low dielectric constant, high light transmission and other properties suitable for touch sensing films, such as polyethylene terephthalate (PET), Cycloolefin polymer (COP), and polymethyl methacrylate (PMMA), etc.

[0031] Such as figure 1 and figure 2 As shown, in some embodiments, the jig structure 100 mainly includes a main body 110 and a spacer 120 . The internal shape and size of the main body 110 match the shape of the film to be formed. The main body 110 mainly includes a bottom plate 112 and a first side wall 114 , wherein the bottom plate 112 may have a square or rectangular plate-like structure. The first side wall 114 is erected on the edge of the bottom plate 112 and surrounds the bottom plate 112 in a peripheral manner. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com