Collision energy absorbing box based on paper cutting pattern design

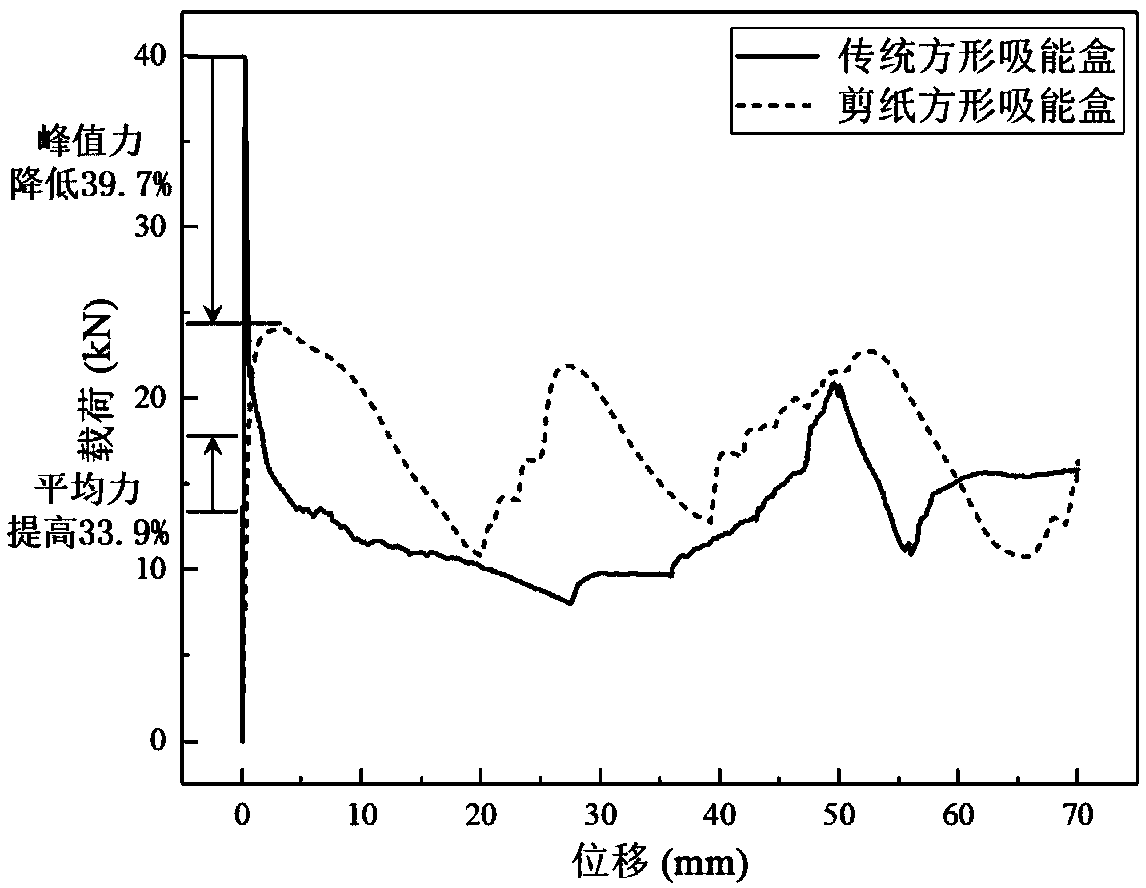

A technology of crash energy absorption and pattern design, which is applied in vehicle safety arrangements, bumpers, transportation and packaging, etc., can solve the problems that affect the actual demand of crash energy absorbing boxes, long production cycle of crash energy absorbing boxes, and excessive initial peak force load. Large and other problems, to achieve strong designability, reduce processing costs, and reduce peak load effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

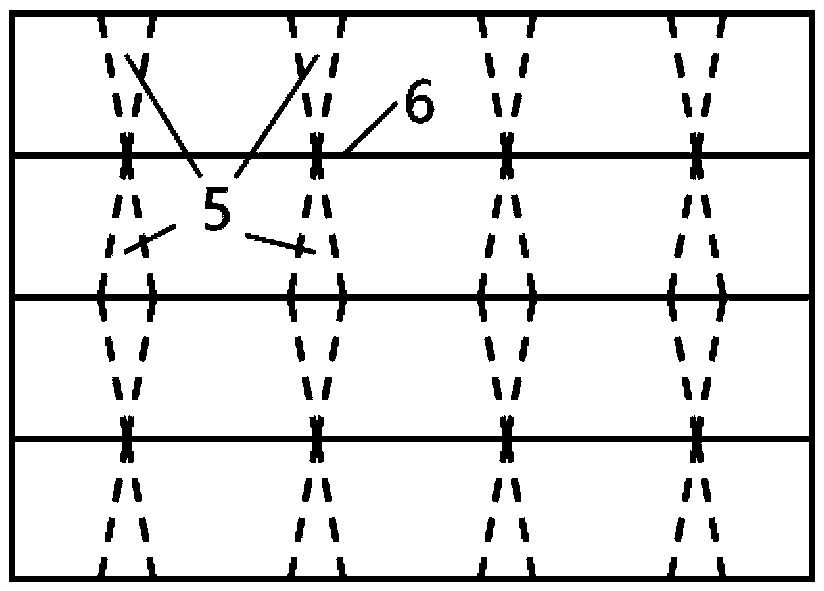

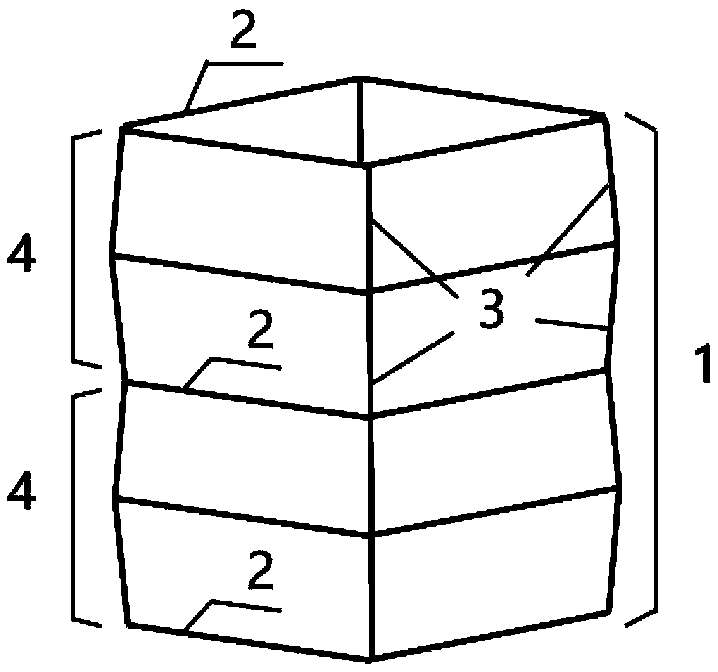

[0038] Embodiment 1: An embodiment of a collision crash box with a paper-cut pattern of a square cross-section as shown in FIG. 1(a) and FIG. 1(b).

[0039] The so-called paper-cut pattern collision energy-absorbing box with square cross-section means that the square cross-section 2 of the square-section paper-cut pattern collision energy-absorbing box is a square. Using the second processing technology, the crash box is assembled from two identical modules. Figure 1(a) is a schematic diagram of the planar expansion of the crash box with a paper-cut pattern of a square section, and Figure 1(b) is a square section The forming drawing of the collision energy-absorbing box with paper-cut pattern is used to specifically describe the shape design of the collision energy-absorbing box 1 with paper-cut pattern of square section. In the present invention, the crash box adopts a modular design concept, wherein the single module 4 of the crash box with a paper-cut pattern of a square sect...

Embodiment 2

[0041] Embodiment 2: Fig. 3(a) and Fig. 3(b) are an embodiment of a collision crash box with variable cross-section and a square-section paper-cut pattern.

[0042] Variable cross-section means that the cross-sections at the same position of different units along the axial direction are changed. Compared with the square-section paper-cut pattern collision crash box described in Embodiment 1, this kind of variable-section crash box only needs Just change the paper-cut pattern in Figure 1(a). The adjusted kirigami pattern is shown in Fig. 3(a). The variable-section square-section kirigami pattern collides with the energy-absorbing box 7 and the variable-section square-section kirigami pattern collides with the single module 8 of the energy-absorbing box, as shown in the figure. In addition to the square section, Crash boxes with other cross-sectional kirigami patterns can also be obtained by modifying the number and shape of the kirigami patterns, and examples are not given here...

Embodiment 3

[0043] Embodiment 3: Fig. 4(a) and Fig. 4(b) are an embodiment of a collision crash box with a square-section paper-cut pattern with an equal-section end frame.

[0044] The so-called square-section paper-cut pattern collision energy-absorbing box with an equal-section end frame means that the section of the energy-absorbing box is square. And from the appearance, it is spliced by ordinary square section tubes and paper-cut pattern tubes. However, it can be seen from Figure 4(a) that the design of kirigami patterns is not limited to a single geometric figure, and can be designed by introducing combined patterns. Similarly, the lengths of the individual modules 10 of the crash box with square-section paper-cut patterns with equal-section end frames in the axial direction can also be different, and the single modules 10 of the crash-absorbing box with square-section paper-cut patterns with equal-section end frames The boundary 3 may also be different after the paper-cut patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com