Uninterrupted temporary ventilation dust removal system during construction period of nuclear island containment plant

A technology of dust removal system and containment, which is applied in the field of uninterrupted temporary ventilation and dust removal system during the construction of nuclear island containment plant, which can solve the problems of obstructing passages and construction working surfaces, hidden safety hazards, workers' breathing needs, etc., to reduce corrosion risk, easy handling and installation, and the effect of reducing noise inside the shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, further illustrate the present invention.

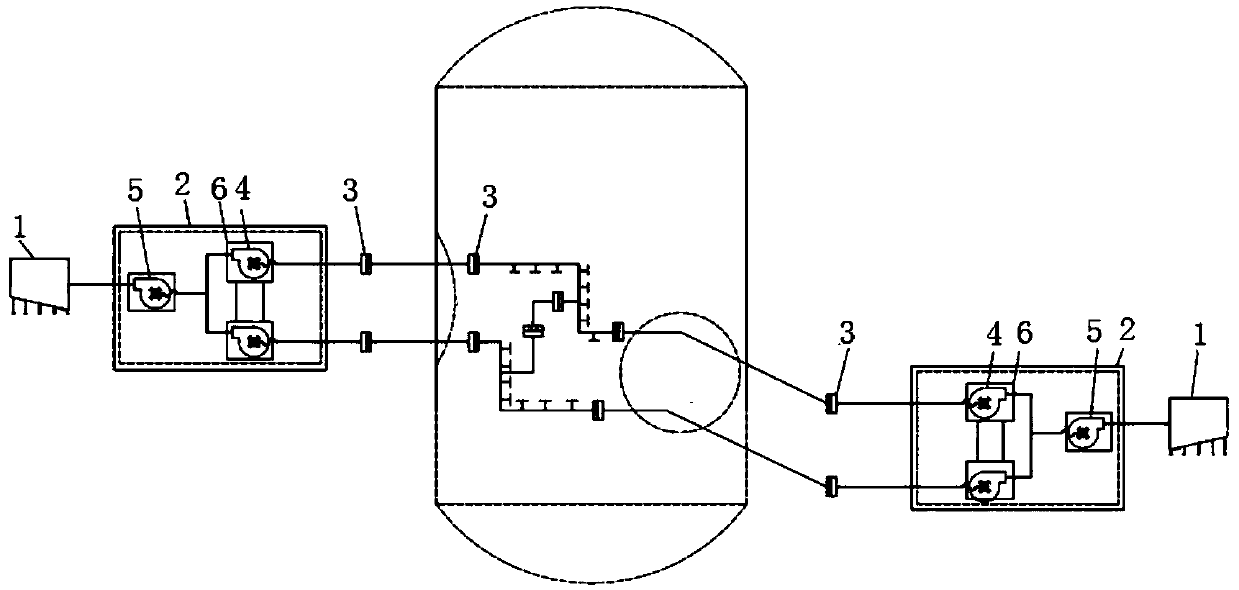

[0022] figure 1 The schematic diagram of the uninterrupted temporary ventilation and dust removal system during the construction of the nuclear island containment plant building is provided for this embodiment. The uninterrupted temporary ventilation and dust removal system during the construction of the nuclear island containment plant building consists of 2 fan modules, 2 air outlets, and multiple It consists of a damper and several duct sections.

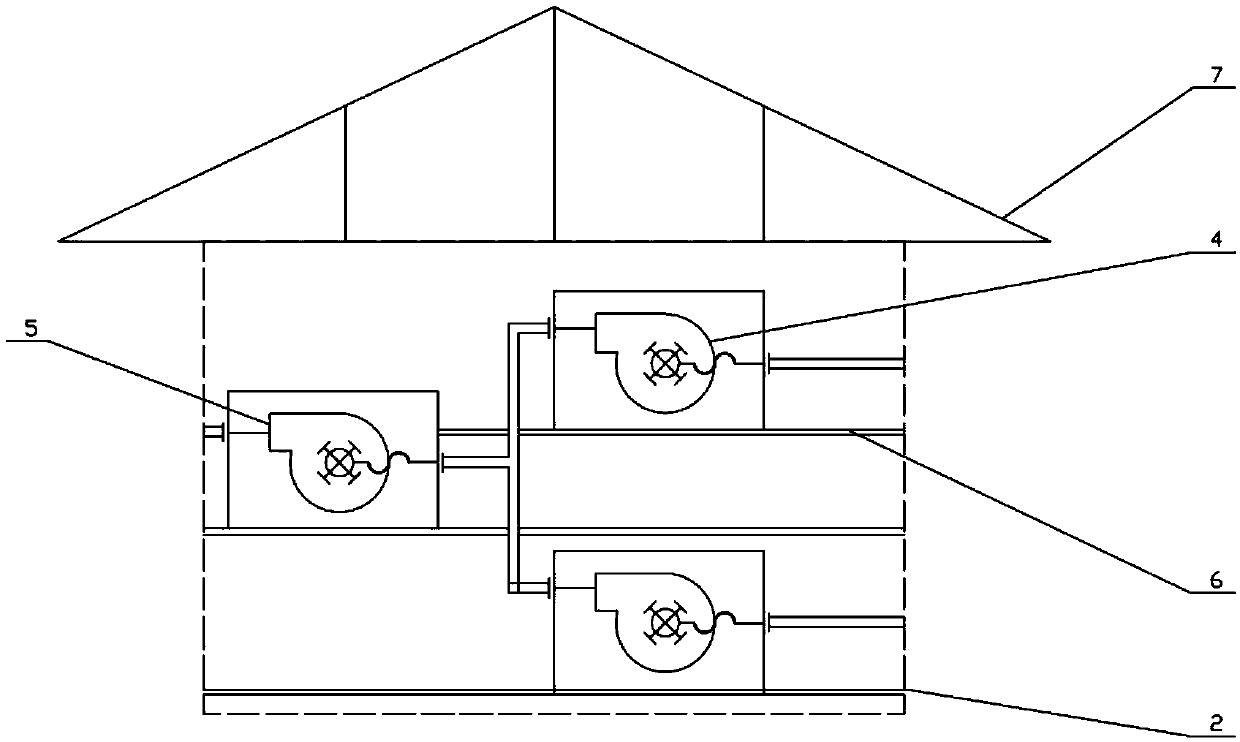

[0023] combine figure 2 , two first fans 4 and one second fan 5 form a group, and are installed in the frame 6 to form a fan module 2 . The two first fans 4 are arranged in parallel and then connected in series with the second fan 5 , that is, the outlets of the two first fans 4 are connected to the inlets of the second fan 5 .

[0024] Wherein, the first blower 4 and the second blower 5 can be commercially available fans with hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com