Thin-film-type active acoustic metamaterial based on magnetic solid coupling

An acoustic metamaterial and film-type technology, applied in the field of acoustic metamaterials, can solve the problems of narrow adjustable range, fixed peak frequency of sound insulation, difficulty in adapting to complex acoustic environments, etc., and achieve simple machining process, fast response and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0039] In this embodiment, the magnets are NdFeB magnets.

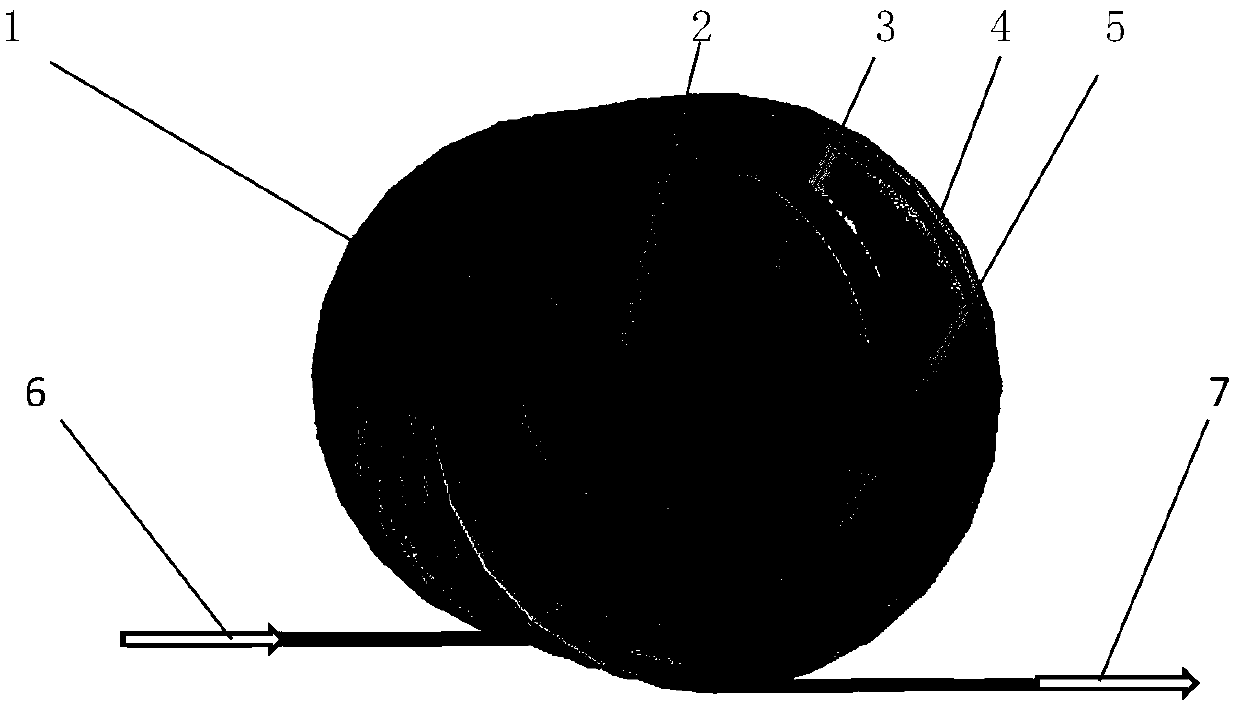

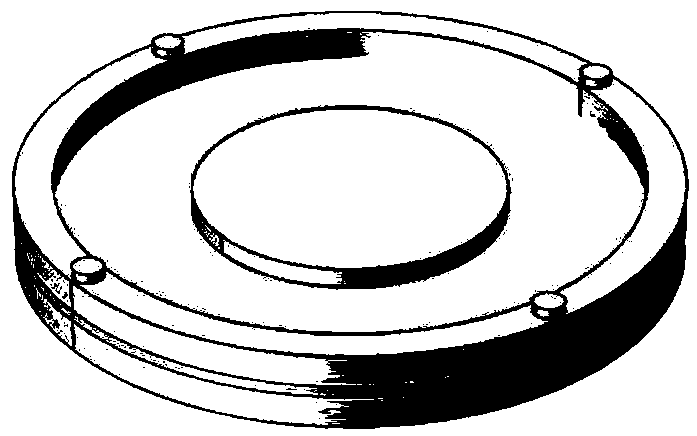

[0040] See figure 1 and figure 2 , the first step: place a circular frame on a horizontal table, and place the silicone film naturally on the upper surface of the circular frame on the desktop;

[0041] Step 2: Align another ring frame with the ring frame on the desktop and place it on the silicone film, clamp the silicone film between the two ring frames, and fix the upper and lower ring frames with four screws to fix the silicone film;

[0042] Step 3: Use a utility knife to cut the silicone film along the outer edge of the ring frame;

[0043] Step 4: Glue the S pole side of the NdFeB magnet to the center of the fixed silicone film;

[0044] Step 5: Wrap a layer of sound-proof tape on the outside of the ring frame to prevent sound leakage;

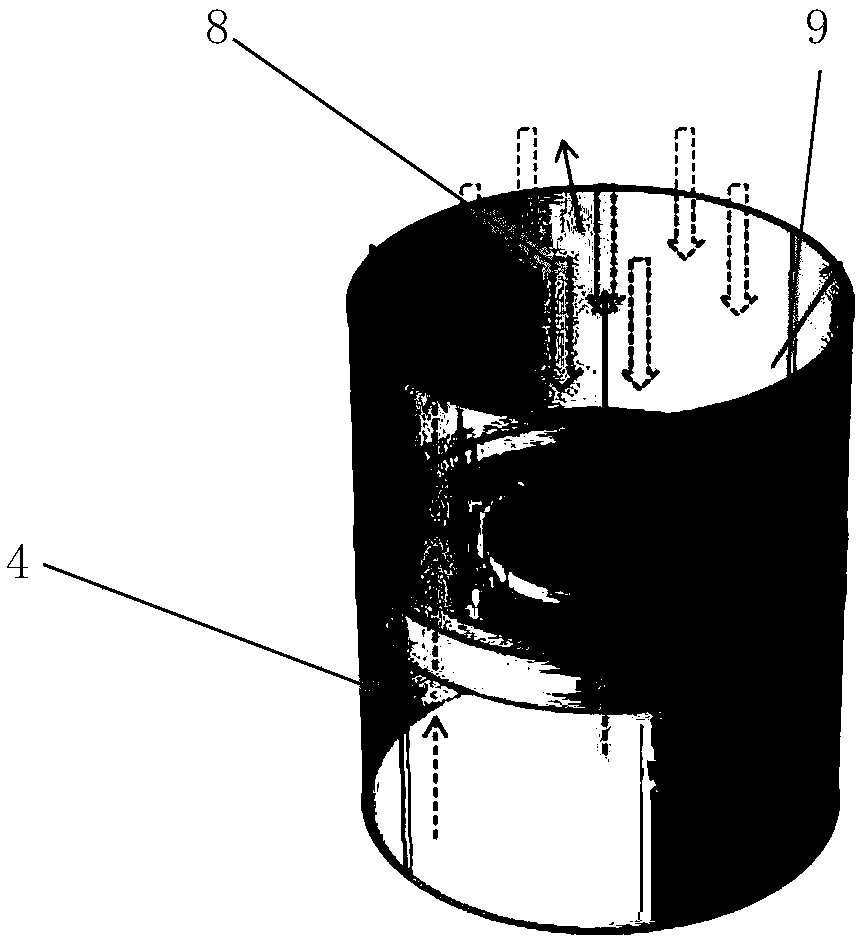

[0045] Step 6: Place t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Inner radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com