Infrared Focal Plane Array

An infrared focal plane and array technology, applied in the field of infrared focal plane arrays, can solve the problems of uneven images of focal plane arrays, different power supply voltages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

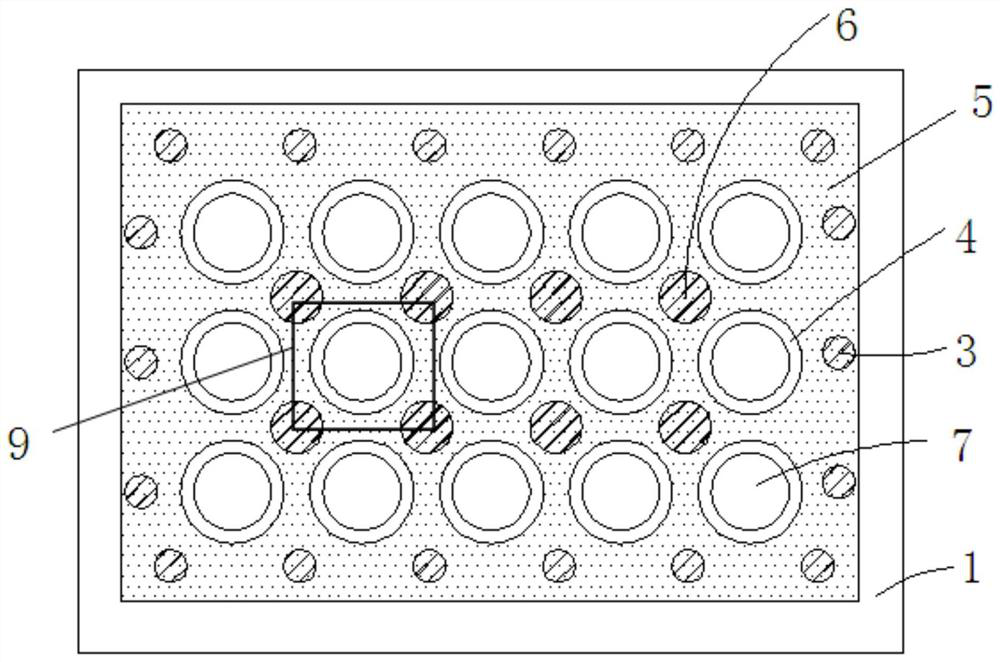

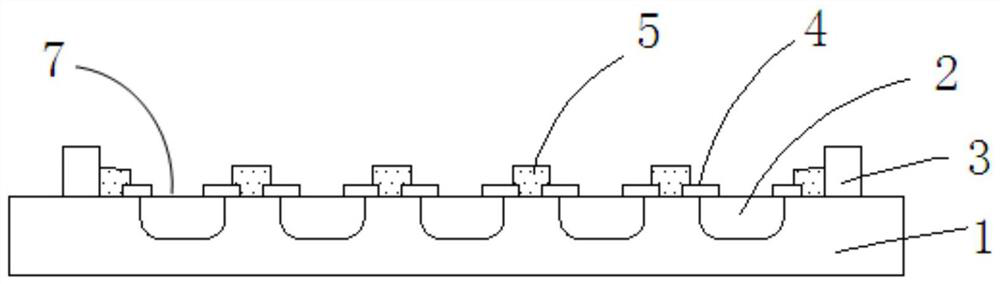

[0043] The present invention is further described below by taking the infrared focal plane array of HgCdTe material (material of epitaxial wafer) with pixels of 800×600 and pixel distance of 15 μm as an example.

[0044] In the traditional process, the current of each pixel is input by the common electrode located at the edge of the array, and then transmitted to the pixel through the HgCdTe epitaxial wafer semiconductor material. Under normal circumstances, the thickness of the epitaxial wafer material is 10-20 μm, and the resistance from the edge of the infrared focal plane array to the center of the focal plane array is more than hundreds of ohms. The working voltage should be lower than 0.12V. Since the pixel is electrically a structure containing a pn junction, the working state of the pixel is different under different operating voltages. This results in that all the pixels in the array are not in the same working state, and finally the electrical uniformity of the enti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com