Active coke regeneration system and method

A technology of activated coke regeneration and regenerator, which is applied in the field of activated coke regeneration system, can solve the problems of potential safety hazards, low pressure, and high energy consumption for regeneration, and achieves improved safety and economy, simple process flow, and safe and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in more detail below. Although preferred embodiments of the present invention are described below, it should be understood that the present invention can be embodied in various forms and should not be limited by the embodiments set forth herein.

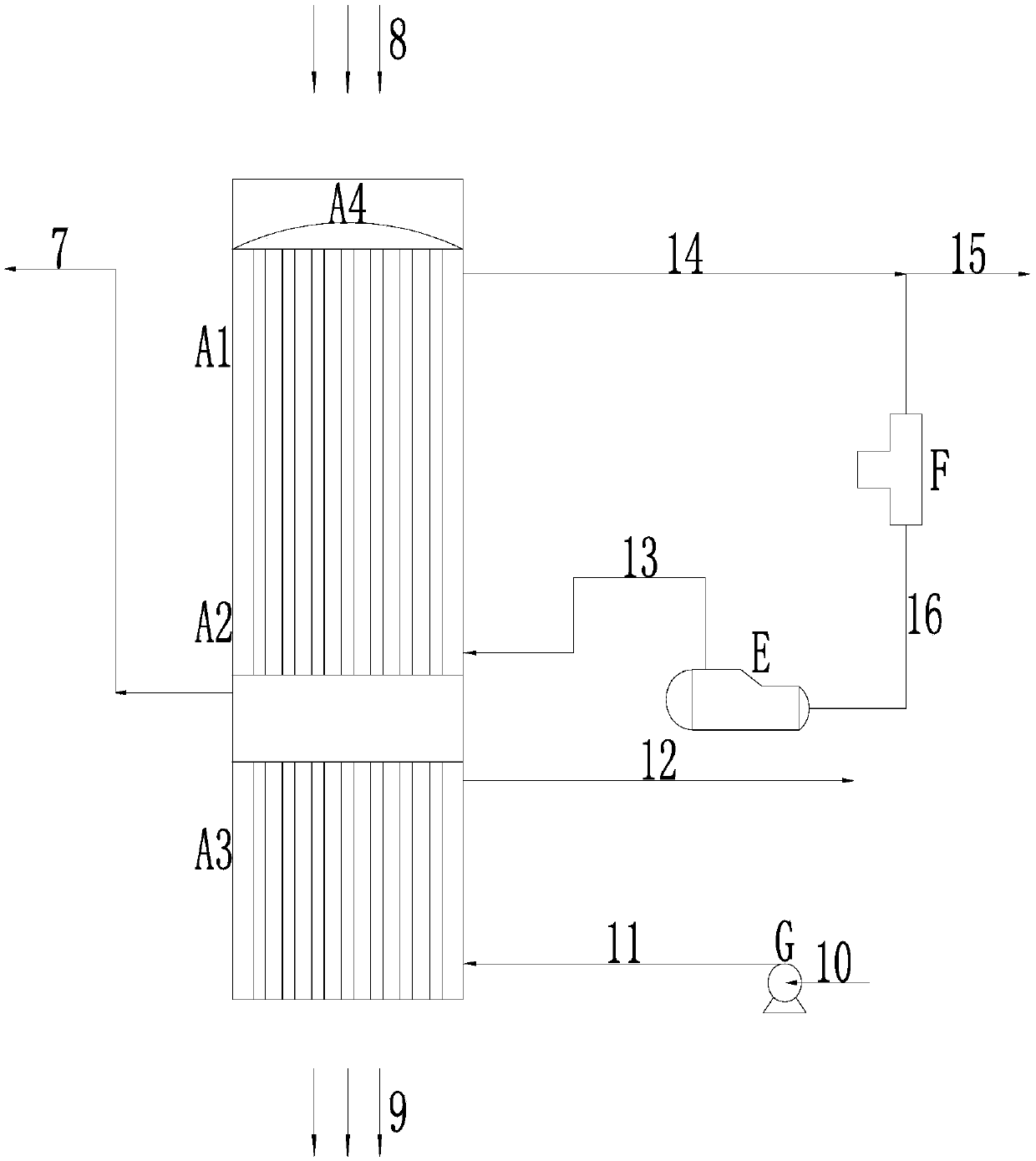

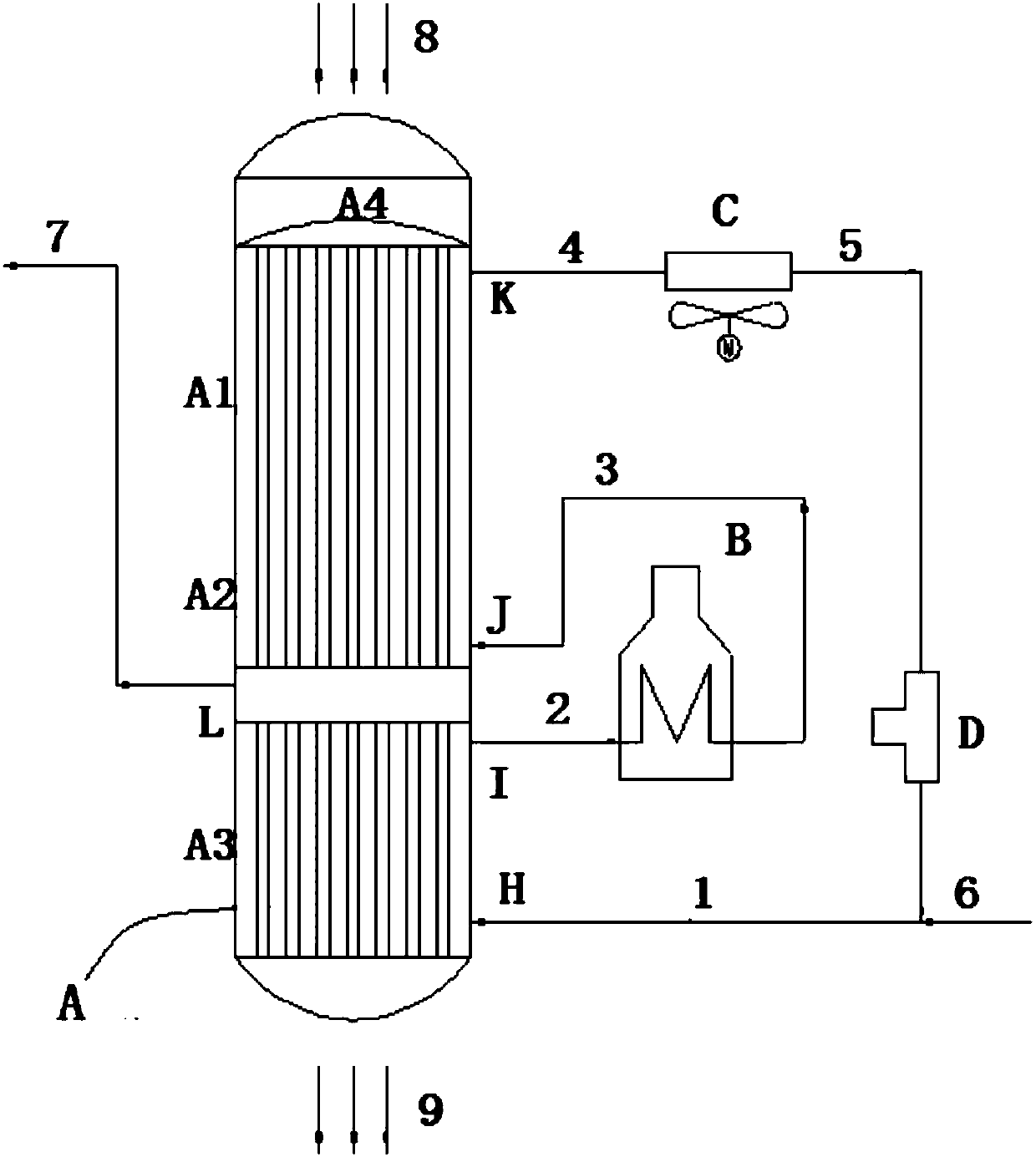

[0026] refer to figure 2 , the active coke regeneration system according to the present invention includes: regenerator A, which is sequentially provided with heating section A1, desorption section A2 and cooling section A3 from top to bottom; the bottom of cooling section A3 is provided with a first nitrogen inlet H, and the top of cooling section A3 A first nitrogen outlet I is provided; a second nitrogen inlet J is provided at the bottom of the desorption section A2; a second nitrogen outlet K is provided at the top of the heating section A1; a heating furnace B is connected to the first nitrogen outlet I of the cooling section A3 and the desorption section A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com