Precise forging method for nozzle shell

A technology of precision forging and nozzle housing, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. Problems such as large machining allowance in die forging process, to achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

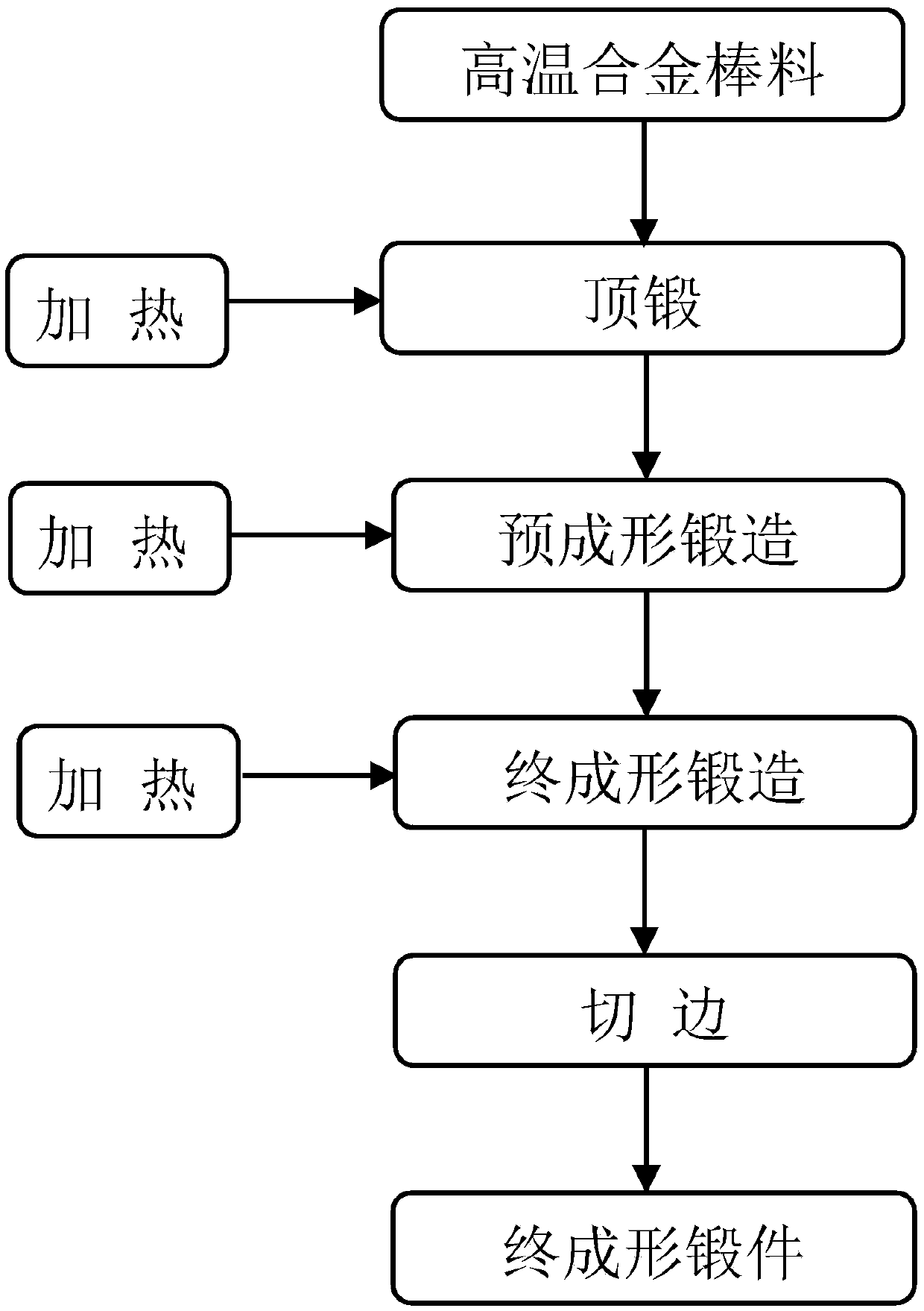

[0036] Below in conjunction with accompanying drawing and specific steps the present invention is described in further detail, see figure 1 , the invention discloses a precision forging method for a nozzle shell; it provides a forging heating furnace, a forging press, a high-temperature alloy raw bar, a billet mold, a forging pre-forming die (abbreviated as a pre-forging die), and a forging final forming die ( Final forging die for short), trimming die; forging heating furnace is electric furnace;

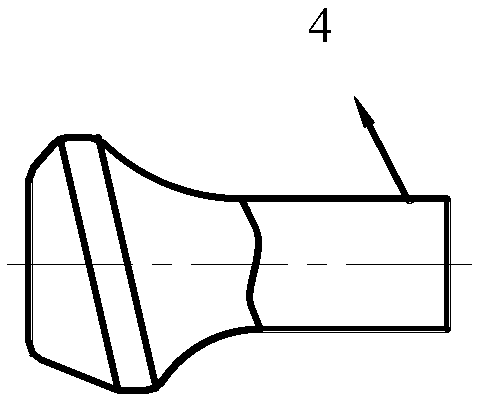

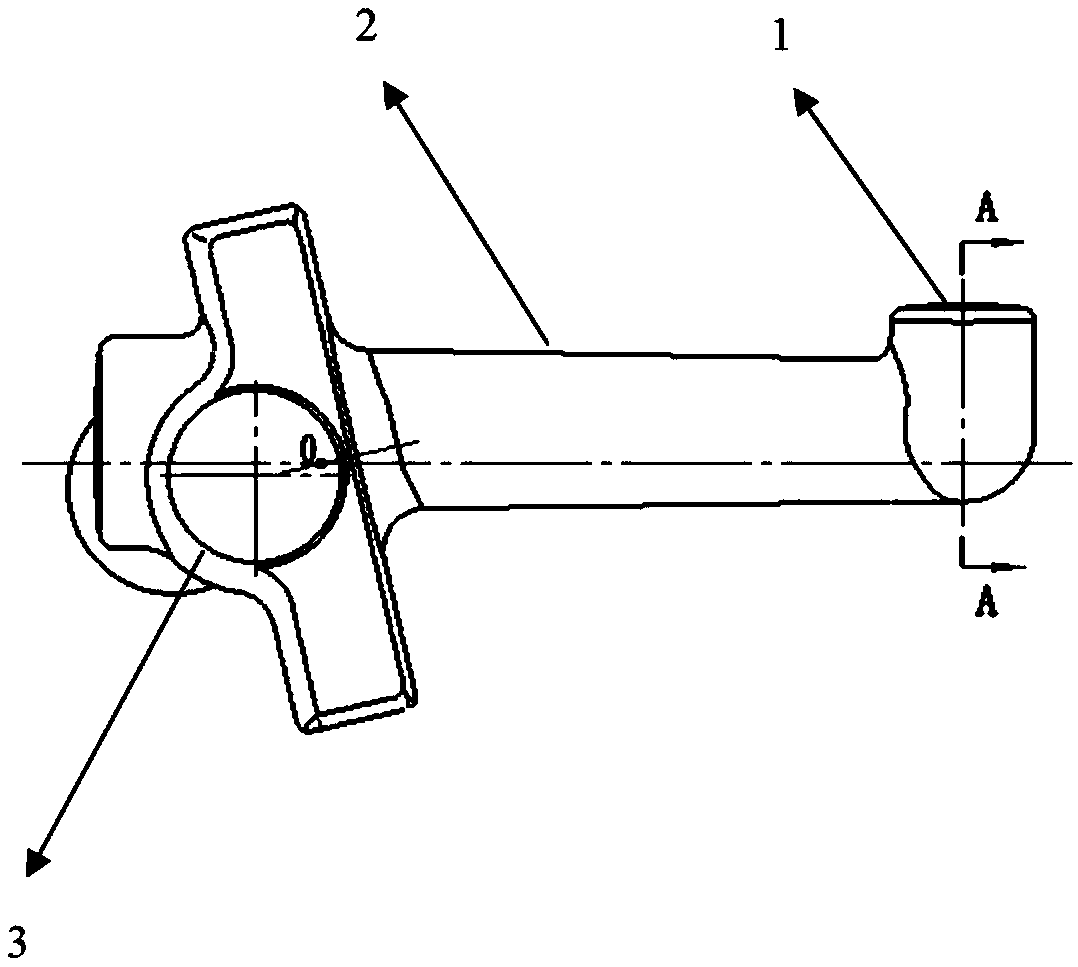

[0037] see image 3 , Figure 4 and Figure 5 , the target nozzle housing includes a head 1, a rod 2 and a mounting seat 3, and the two ends of the rod 2 are respectively fixedly connected with the head 1 and the mounting seat 3; see figure 2 The shank 2 of all process parts during machining is the process shank 4 . This method is applicable to common superalloys, such as nickel-based superalloys or iron-based superalloys.

[0038] combine figure 1 , the precision forging of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com