A laser-excited ultrasonic energy field assisted plasma arc-loaded powder additive manufacturing method

A plasma arc and additive manufacturing technology, which is applied in the field of high-efficiency additive manufacturing, can solve the problems of inability to stimulate the impact molten pool, low structural density of formed components, and unobvious effect of grain refinement, etc., to achieve improved Effect of heterogeneous nucleation rate, promotion of uniform nucleation, and grain growth refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

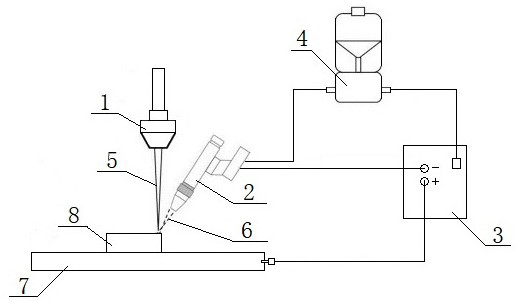

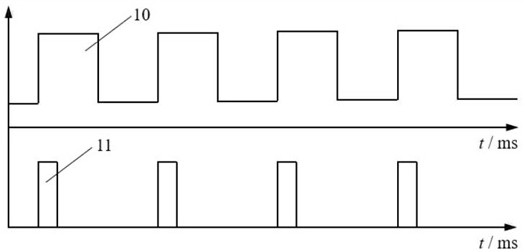

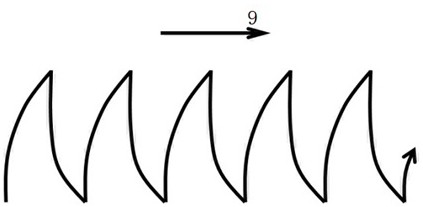

[0029] Embodiment 1, a laser-excited ultrasonic energy field assisted plasma arc-borne powder additive manufacturing method, which includes the following steps:

[0030] 1. The substrate 7 is made of 304 stainless steel plate with a thickness of 4 mm. The powder material in the powder feeder 4 has a particle size of 200-300 mesh austenitic stainless steel powder. The protective gas and ion gas used in the forming process are pure argon. The substrate 7 is horizontally fixed on the additive manufacturing platform, and the substrate 7 is connected to the positive pole of the plasma arc power supply 3 , and the plasma arc welding torch 2 is connected to the negative pole of the plasma arc power supply 3 . Adjust the plasma arc welding torch 2 so that the direction of the powder flow emitted by the plasma arc welding torch forms an included angle of 25° with the vertical plane, and adjust the laser 1 so that it is perpendicular to the surface of the substrate 7 . Then calibrate th...

Embodiment 2

[0035] Embodiment 2, a laser-excited ultrasonic energy field assisted plasma arc-borne powder additive manufacturing method, which includes the following steps:

[0036] 1. The substrate 7 is made of 304 stainless steel plate with a thickness of 4 mm. The powder material in the powder feeder 4 has a particle size of 200-300 mesh austenitic stainless steel powder. The protective gas and ion gas used in the forming process are all pure argon; The substrate 7 is horizontally fixed on the additive manufacturing platform, and the substrate 7 is connected to the positive pole of the plasma arc power supply 3 , and the plasma arc welding torch 2 is connected to the negative pole of the plasma arc power supply 3 . Adjust the plasma arc welding torch 2 so that the direction of the powder flow from the plasma arc welding torch forms an angle of 15° with the vertical plane, and adjust the laser 1 so that it is perpendicular to the surface of the substrate 7 . Then calibrate the relative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com