Centralized armature independent suspension rear axle

A technology of independent suspension and electric drive, which is applied in the direction of suspension, elastic suspension, and cantilever installed on the pivot, etc., which can solve the problems of comfort, low handling stability, and large space occupied by rigid electric drive axles. Achieve the effect of improving the bearing capacity and rotation flexibility, realizing the lightweight of the whole bridge, and improving the comfort of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

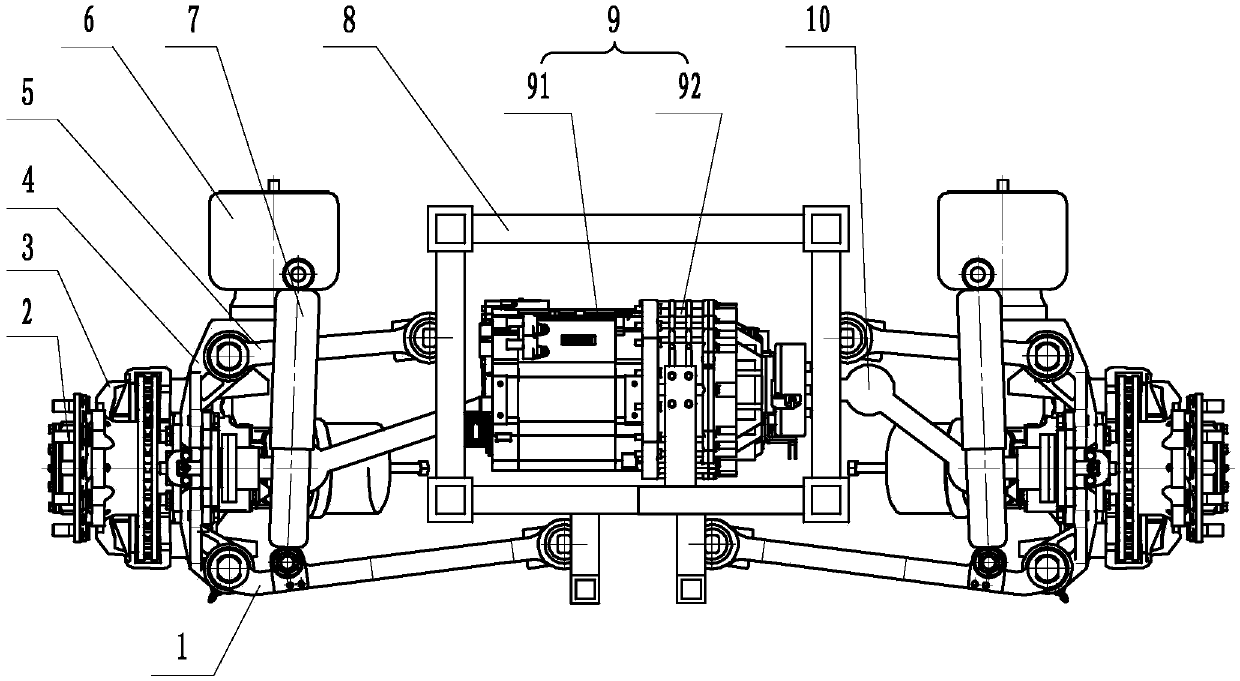

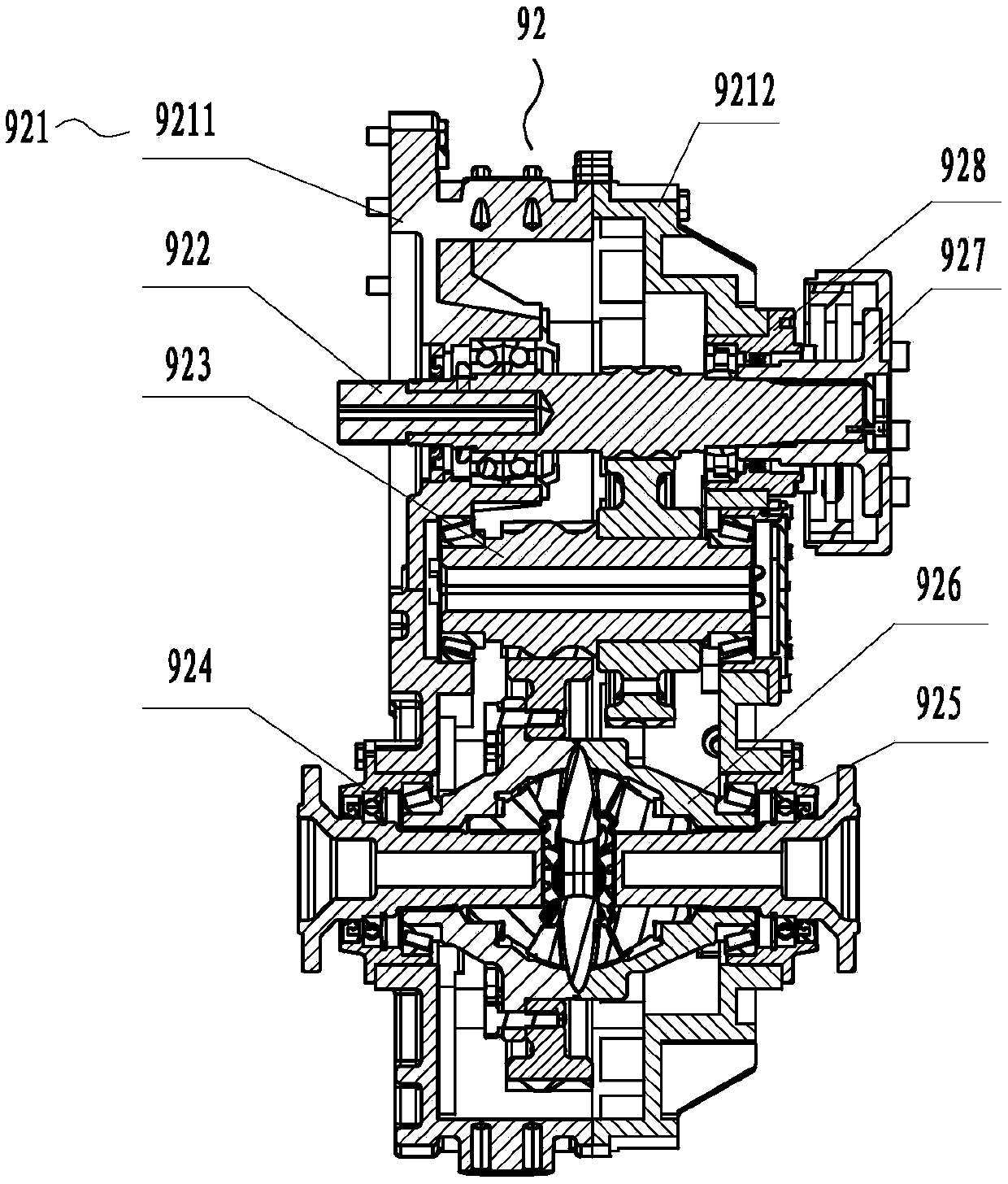

[0043] A centralized electric drive independent suspension rear axle, including a lower swing arm 1, a hub assembly 2, a brake assembly 3, a support frame assembly 4, an upper swing arm 5, an airbag assembly 6, a shock absorber assembly 7, Vehicle frame 8, power assembly 9, universal joint transmission shaft 10, described lower swing arm 1, wheel hub assembly 2, brake assembly 3, support frame assembly 4, upper swing arm 5, air bag assembly 6, reducing The vibrator assembly 7 is respectively symmetrically installed on both sides of the vehicle frame 8; wherein:

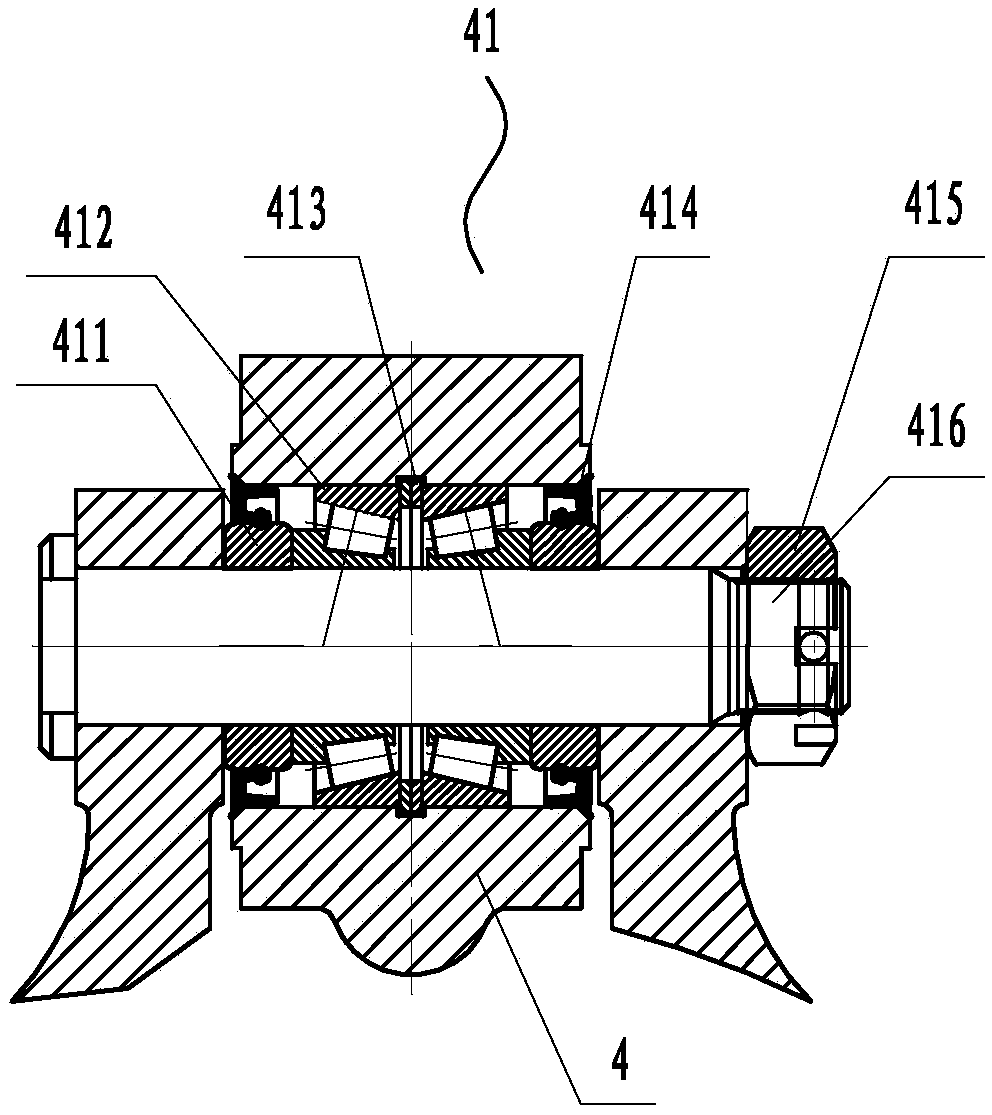

[0044]The support frame assembly 4 is used as the supporting body of the entire bridge, the beginning of the upper swing arm 5 is hinged to the upper part of the support frame assembly 4 through the pin assembly 41, and the end of the upper swing arm 5 is fastened to the vehicle frame 8 to support The frame assembly 4 can flexibly rotate around the end of the upper swing arm 5; the beginning of the lower swing arm 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com