Helicopter rotor wing operating device and rotor wing device

A helicopter rotor and control device technology, applied in the field of unmanned aerial vehicles, can solve the problems of complex swash plate structure, difficult manufacturing and assembly, low control efficiency, etc., achieve stable and efficient output, improve space utilization, and simplify the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

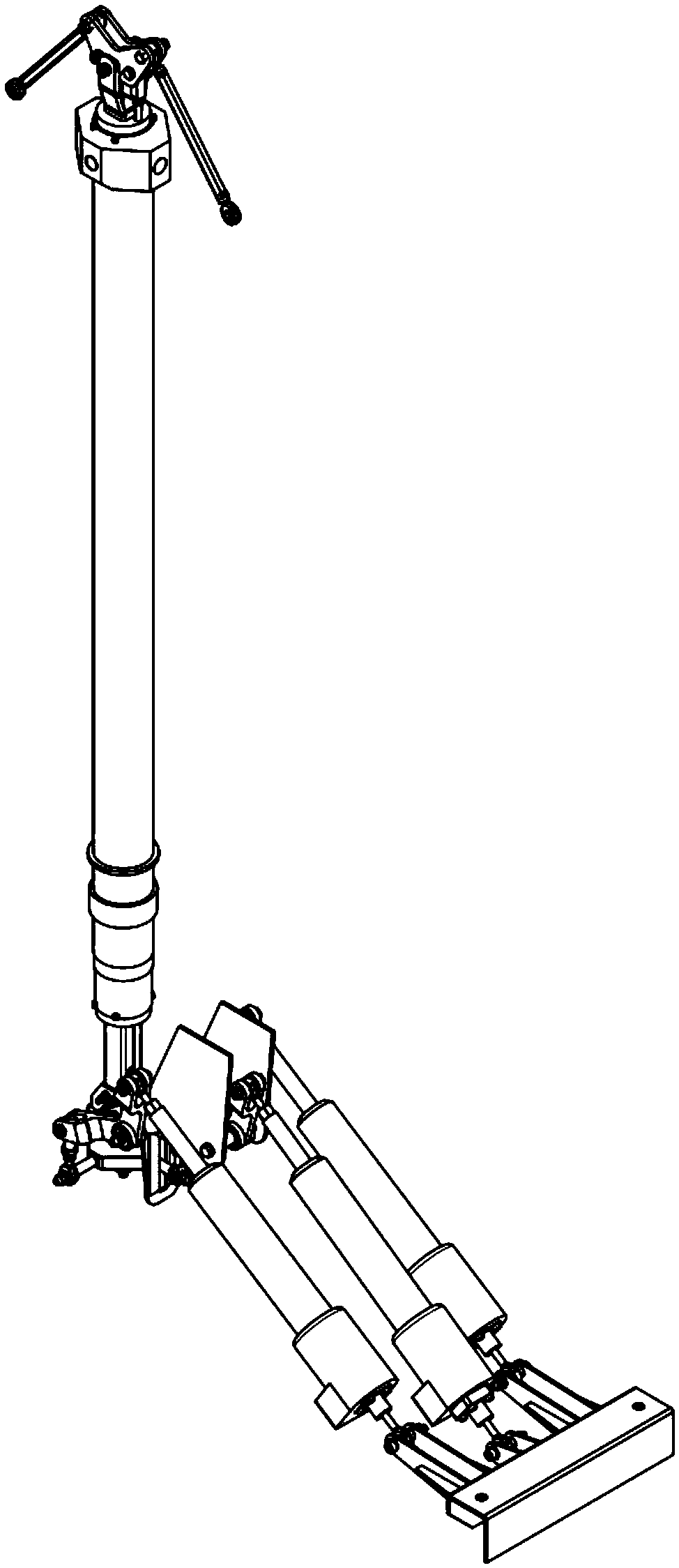

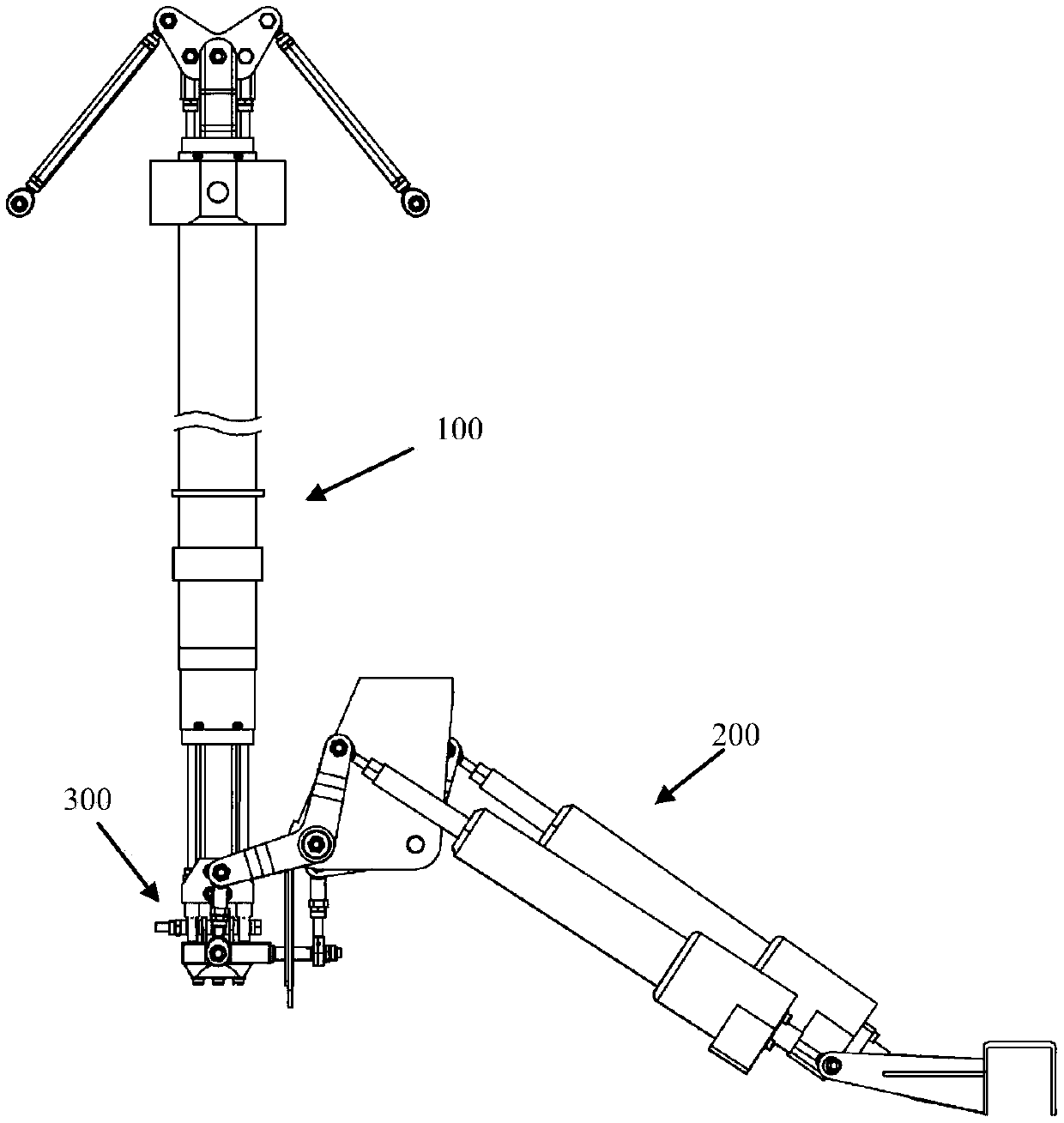

[0034] A kind of helicopter rotor control device of the present invention is characterized in that: comprises steering gear drive assembly 200, swash plate assembly 300 and total moment slider assembly 100,

[0035] The steering gear drive assembly includes three linear steering gears 210 whose tail ends are rotatably connected to the body. The body is rotatably connected to an L-shaped control arm 211;

[0036] The swash plate assembly includes a swash plate 310, a swash plate rotation shaft 311 rotatably set in the swash plate, and the swash plate arm 312, 313, the swash plate support arm is hinged to the other end of the L-shaped control arm through the transmission rod 212;

[0037] The total moment slide bar assembly includes a central joint bearing 111 arranged at the lower end of the total moment slide bar 110, corresponding to a side joint bearing 121 arranged at the lower end of the long tie rod 120, and the balls of the central joint bearing 111 and the side joint b...

Embodiment 2

[0047] As a specific embodiment, the fixed end of the linear steering gear is connected to the body through a joint bearing, and the output end of the linear steering gear is connected to the L-shaped control arm through a joint bearing.

[0048] When installing the fixed end of the linear steering gear, first connect the fixed end of the linear steering gear to the mounting part of the steering gear through bolts, then connect the mounting part of the steering gear to the joint bearing through threads, and finally fix the joint bearing to the installation position of the body with bolts. When installing the output end of the linear servo, first connect the joint bearing and the output end of the linear servo with threads. Then the joint bearing and the L-shaped control arm are fixed with bolts, and finally the L-shaped control arm is fixed on the corresponding position of the body mounting part with bolts using two rolling bearings and a body support washer. At the other end ...

Embodiment 3

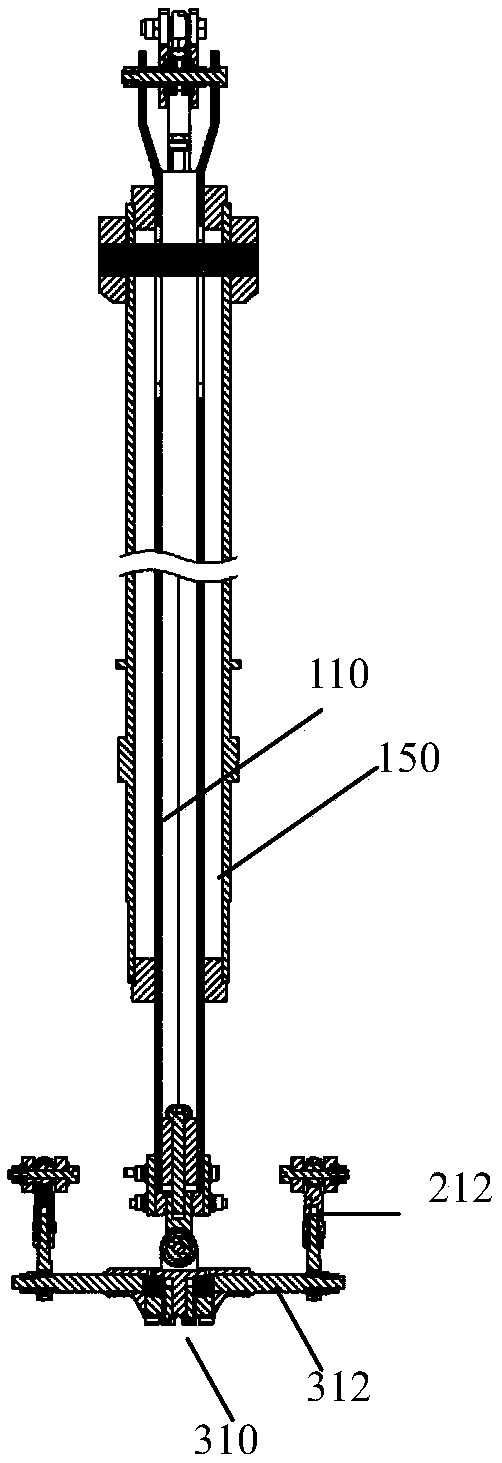

[0052] A helicopter rotor device of the present invention includes the rotor control device and the tubular rotor shaft 150, the total moment slide bar and the long tie rod are located in the rotor shaft, and the upper end of the rotor shaft is provided with a transverse Through the positioning pin shaft, the collective distance sliding rod is formed with an axial long hole matching the positioning pin shaft.

[0053] The limit pin of the collective slide bar is installed in the center of the rotor shaft, and only slides within a certain range in the up and down direction. Its sliding range is 10mm larger than the stroke range required by the rotor system. The collective distance slider limit pin plays a protective role on the collective distance slider. Prevent misuse from causing damage to the entire control mechanism.

[0054] Wherein, the upper and lower ends of the rotor shaft 150 are respectively connected with bolts to fix the limit block of the linkage rod, and the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com