Air floating type glass conveying device

A conveying device and air-floating technology, applied in the field of air-floating glass conveying devices, can solve the problems of poor glass plate stability, glass plate scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

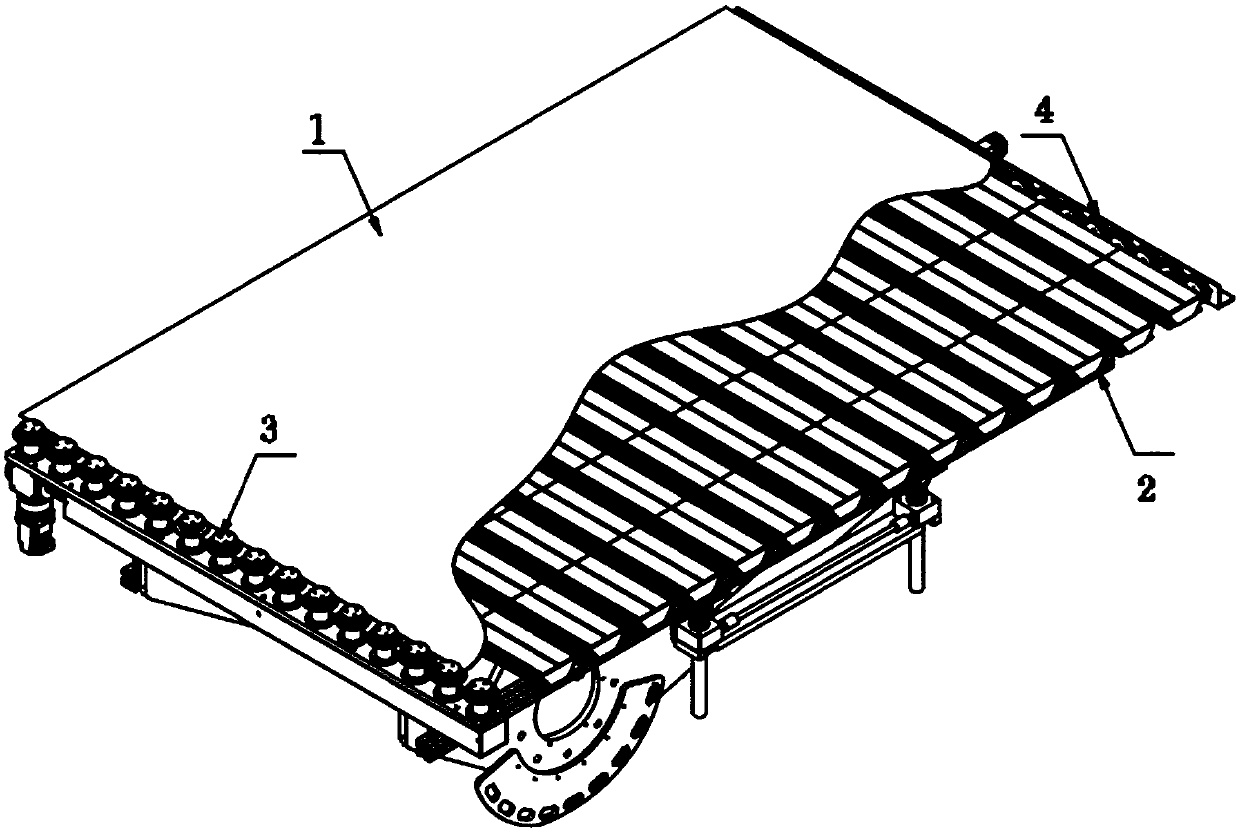

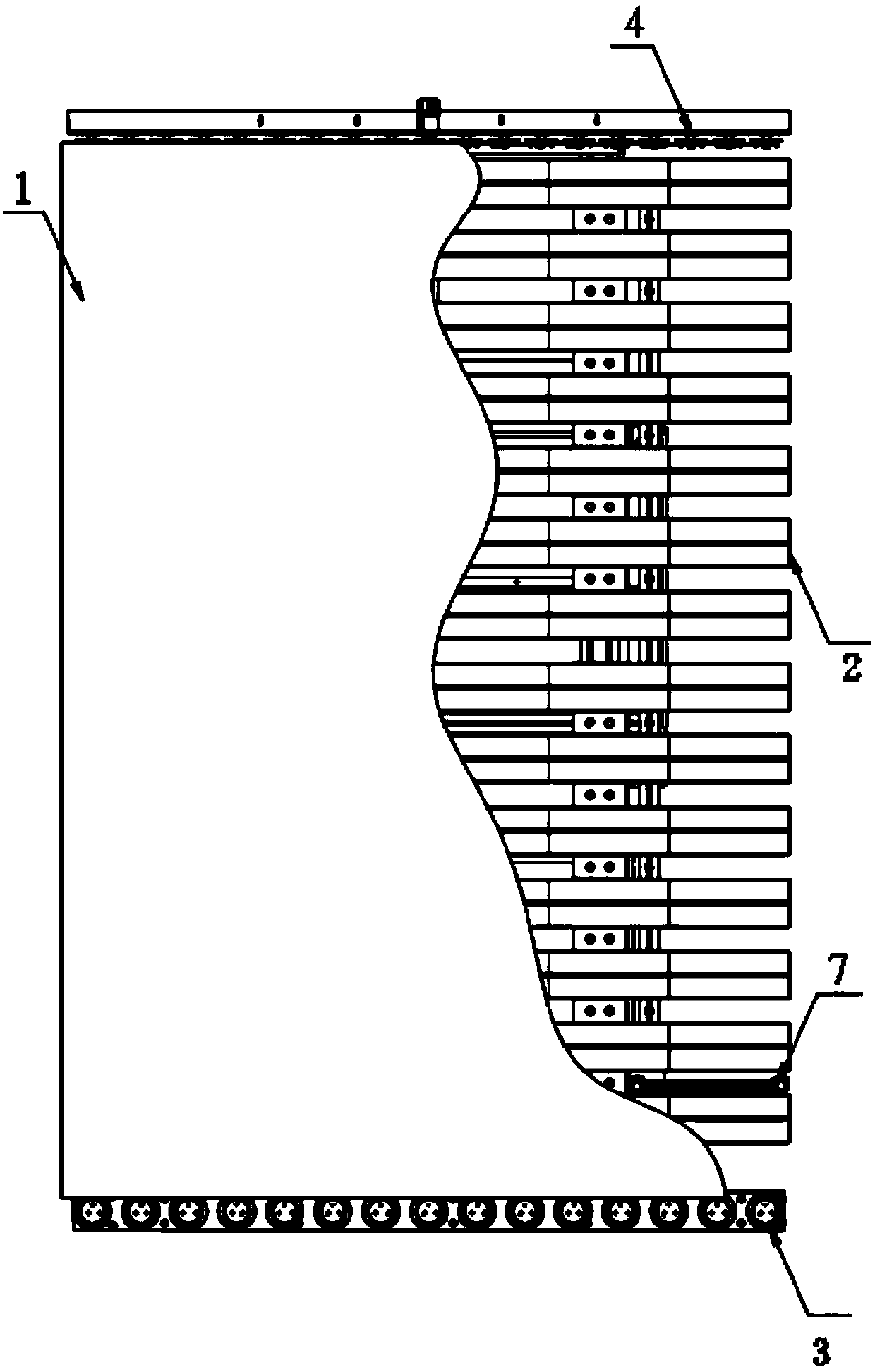

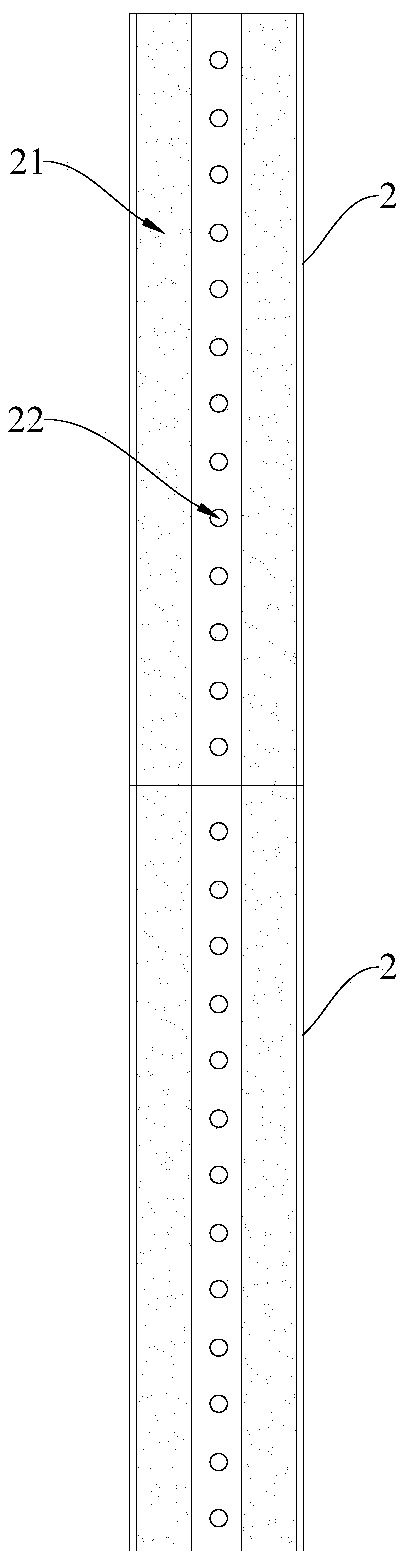

[0032] figure 1 It is a schematic diagram of the first viewing angle of the air-floating glass conveying device in the embodiment of the present invention; figure 2 It is a schematic view of the second viewing angle of the air-floating glass conveying device in the embodiment of the present invention. Please refer to figure 1 and figure 2 , the present embodiment provides an air-floating glass conveying device, which includes an air-floating mechanism, a main driving mechanism 3 and an auxiliary driving mechanism 4 arranged on opposite sides of the air-floating mechanism, and a turning mechanism arranged below the air-floating mechanism And lifting mechanism 6.

[0033] In this embodiment, the air flotation mechanism is used to blow up the glass plate 1 so that the glass plate 1 is suspended on the upper surface of the air flotation mechanism. The main driving mechanism 3 is used to abut against the lower side of the glass plate 1 when the air floating mechanism is tilte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap