PC/ASA Plastics for Automotive Interior Parts and Its Production Process

A technology of automotive interior parts and production technology, applied in the field of plastics, can solve the problems that the properties of PC/ASA alloy materials cannot meet the needs, and achieve the effects of high mechanical properties, low cost, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

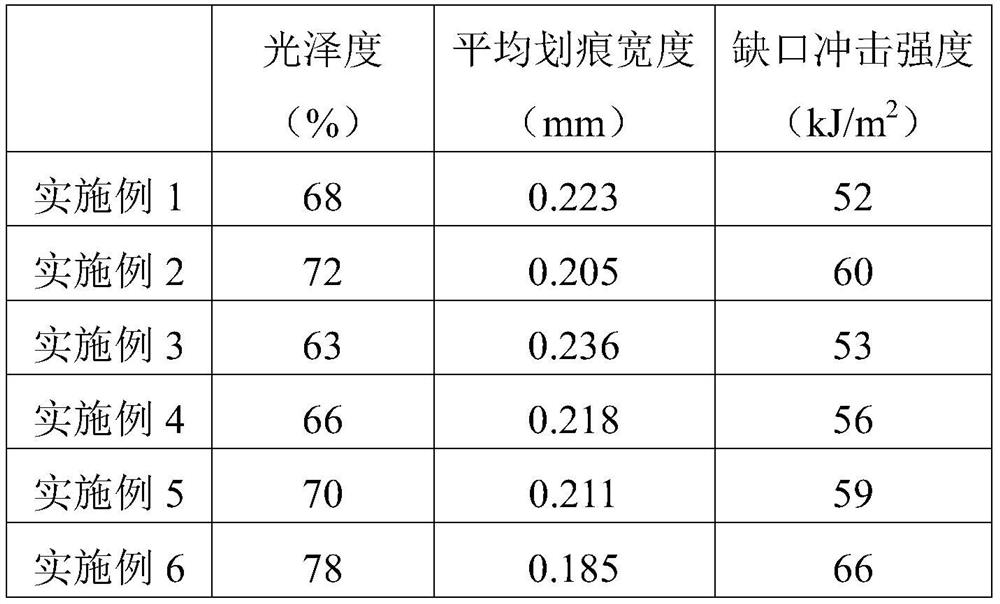

Examples

Embodiment 1

[0039] The production process of PC / ASA plastics for automotive interior parts comprises the following steps:

[0040] (1) Weigh each raw material by weight: 80 parts of polycarbonate, 20 parts of acrylonitrile-styrene-acrylate graft copolymer, 3 parts of compatibilizer, 1.2 parts of lubricant, 0.5 part of antioxidant, 0.4 parts of stabilizer;

[0041] (2) each raw material is mixed with a high-speed mixer for 8 minutes at a speed of 600r / min to obtain a compound;

[0042] (3) Add the mixture to a twin-screw extruder for melt blending. The screw diameter of the extruder is 35mm and the aspect ratio is 32; the temperature in the first zone is 200°C, the temperature in the second zone is 210°C, and the temperature in the third zone The temperature of zone 4 is 220°C, the temperature of zone 4 is 230°C, the temperature of zone 5 is 240°C, the temperature of zone 6 is 240°C, the temperature of zone 7 is 250°C, the temperature of zone 8 is 250°C, the temperature of zone 9 is 245°C...

Embodiment 2

[0048] The production process of PC / ASA plastics for automotive interior parts comprises the following steps:

[0049] (1) Weigh each raw material by weight: 80 parts of polycarbonate, 20 parts of acrylonitrile-styrene-acrylate graft copolymer, 3 parts of compatibilizer, 1.2 parts of lubricant, 0.5 part of antioxidant, 0.4 parts of stabilizer;

[0050] (2) each raw material is mixed with a high-speed mixer for 8 minutes at a speed of 600r / min to obtain a compound;

[0051] (3) Add the mixture to a twin-screw extruder for melt blending. The screw diameter of the extruder is 35mm and the aspect ratio is 32; the temperature in the first zone is 200°C, the temperature in the second zone is 210°C, and the temperature in the third zone The temperature of zone 4 is 220°C, the temperature of zone 4 is 230°C, the temperature of zone 5 is 240°C, the temperature of zone 6 is 240°C, the temperature of zone 7 is 250°C, the temperature of zone 8 is 250°C, the temperature of zone 9 is 245°C...

Embodiment 3

[0058] The production process of PC / ASA plastics for automotive interior parts comprises the following steps:

[0059] (1) Weigh each raw material by weight: 80 parts of polycarbonate, 20 parts of acrylonitrile-styrene-acrylate graft copolymer, 3 parts of compatibilizer, 1.2 parts of lubricant, 0.5 part of antioxidant, 0.4 parts of stabilizer;

[0060] (2) each raw material is mixed with a high-speed mixer for 8 minutes at a speed of 600r / min to obtain a compound;

[0061] (3) Add the mixture to a twin-screw extruder for melt blending. The screw diameter of the extruder is 35mm and the aspect ratio is 32; the temperature in the first zone is 200°C, the temperature in the second zone is 210°C, and the temperature in the third zone The temperature of zone 4 is 220°C, the temperature of zone 4 is 230°C, the temperature of zone 5 is 240°C, the temperature of zone 6 is 240°C, the temperature of zone 7 is 250°C, the temperature of zone 8 is 250°C, the temperature of zone 9 is 245°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com