Compressed air microporous stirring device for surface treatment tank liquor

A technology of compressed air and surface treatment, applied in the field of microporous stirring device and compressed air microporous stirring device, can solve the problems of poor consistency of anodized film layer and coating layer, uneven anodized film layer or coating layer, uneven current distribution, etc. , to achieve the uniform composition of the bath liquid, solve the poor heat dissipation effect, and uniformly improve the thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

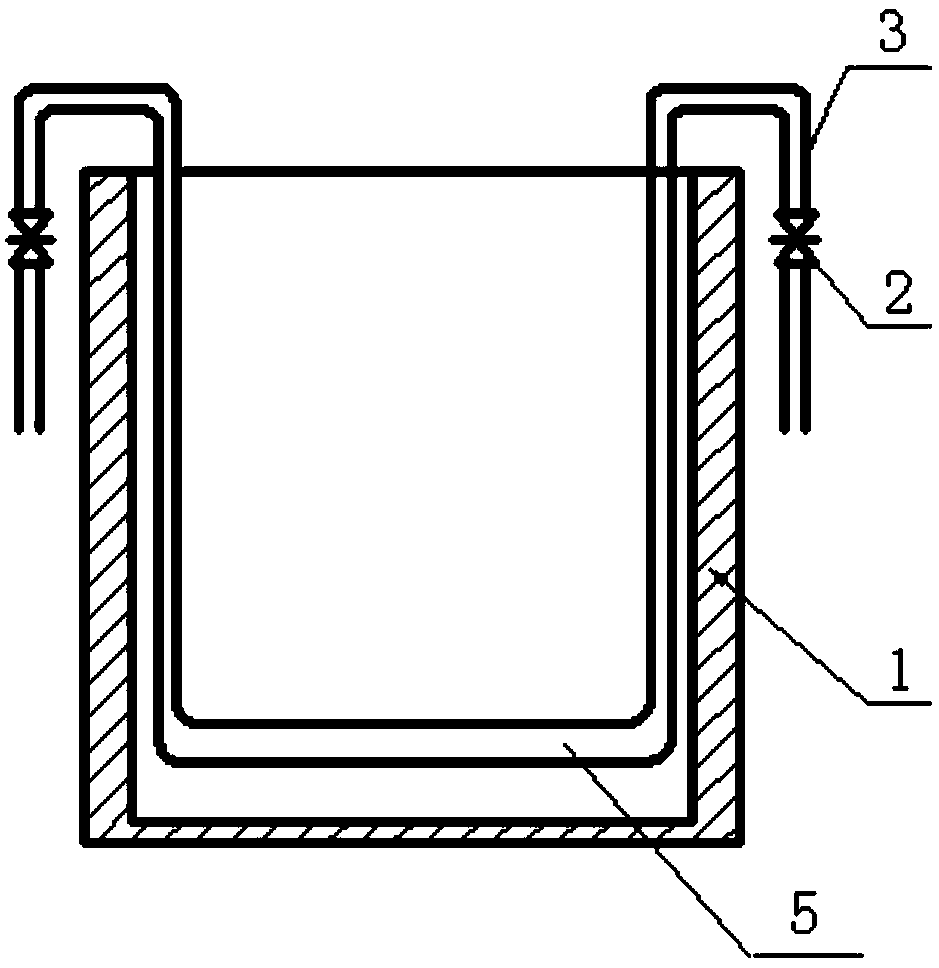

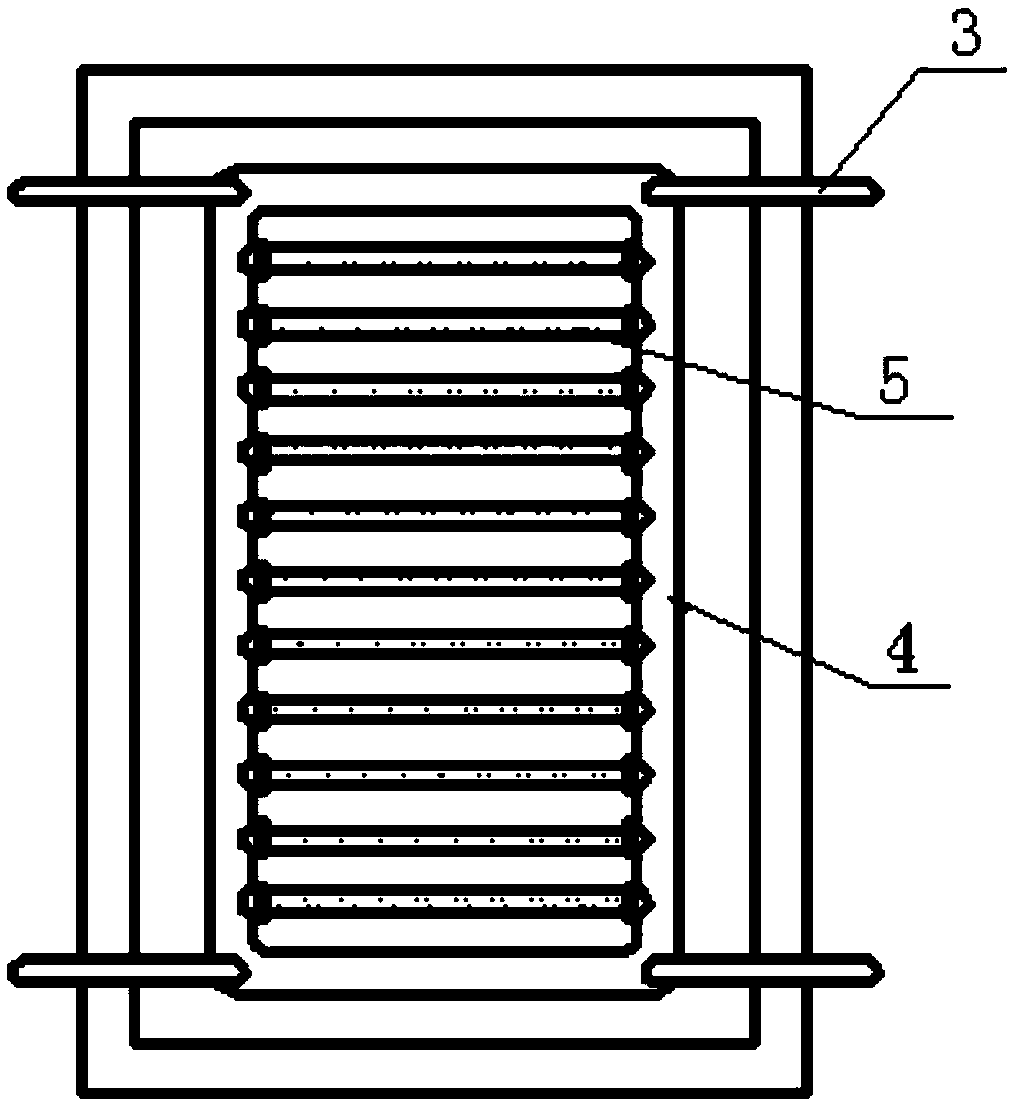

[0019] see figure 1 , The present invention provides a compressed air microporous stirring device for surface treatment bath liquid, comprising five parts including a compressed air source, an air inlet pipe 3, an air inlet regulating valve 2, an air equalizing pipe 4 and a microporous stirring pipe 5. The compressed air source connects with the microporous stirring tube through the air inlet pipe and the air equalizing pipe in turn; the microporous stirring pipe is a PE polymer polyethylene microporous pipe with micron-sized pores, and the air inlet pipe is provided with an air inlet regulating valve.

[0020] Among them: the air intake pipe 3 is made of PE polymer polyethylene, which is connected to the compressed air source to provide compressed air for the overall mixing system; the air intake regulating valve 2 is a plastic cut-off valve or gate valve, which mainly controls the flow of compressed air entering the mixing system The flow rate and the quantity and strength o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com