A kind of ultra-long graphene fiber and preparation method thereof

A graphene fiber and graphene technology, applied in fiber chemical characteristics, rayon manufacturing, textiles and paper making, etc., can solve problems such as long production cycle, graphene fiber length and performance limitations, complex graphene fiber processing technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

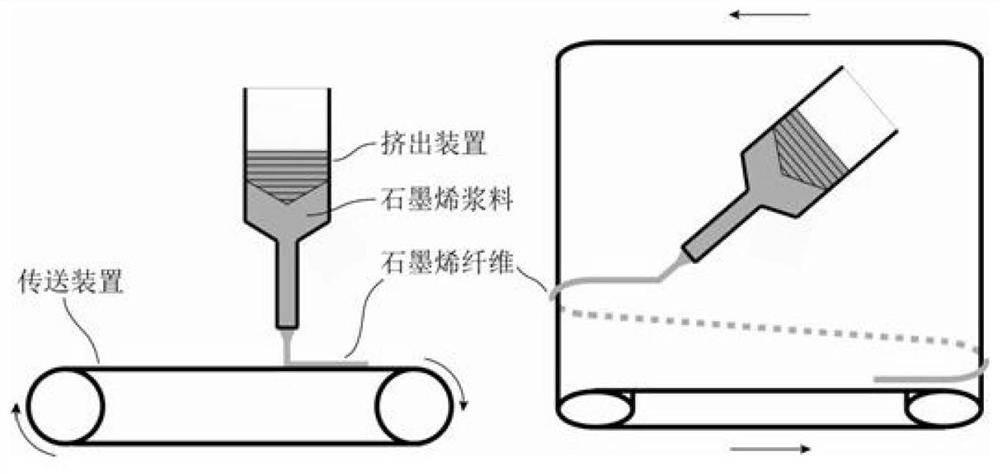

[0031] The preparation method of the ultra-long graphene fiber of the present invention has the advantages of simple process, mild conditions, strong controllability and easy industrial production. The graphene fiber prepared by the method of the invention has uniform structure and excellent performance. The preparation method of ultra-long graphene fiber provided by the present invention is exemplarily described below, such as figure 1 shown.

[0032] Preparation of graphene slurry. The invention utilizes an ultrasonic process to uniformly disperse graphene in absolute ethanol, and obtains graphene slurry that can be used to prepare fibers by adjusting the ratio of graphene to a solvent, a dispersant, and a binder. Wherein, the graphene is dispersed in the solvent, and the mass ratio of the graphene to the solvent may be 1:5˜1:200. The solvent can be absolute ethanol, water, acetone, etc. The mass ratio of the dispersant to graphene may be 1:0.1˜1:10. The dispersant can ...

Embodiment 1

[0041] A kind of preparation method of ultra-long graphene fiber, concrete steps are:

[0042] (1) Use ethylene glycol butyl ether as a dispersant, respectively control the mass ratio of graphene to ethylene glycol butyl ether to 3:1, and the mass ratio of graphene to absolute ethanol to 1:5, and use ultrasonic technology to homogenize the graphene Disperse in absolute ethanol to obtain a graphene suspension, the ultrasonic power is 100W, and the ultrasonic time is 1h;

[0043] (2) Using polyvinyl butyral and dibutyl phthalate as binders, adding graphene suspension, and ultrasonically dispersing to obtain graphene slurry that can be used to prepare fibers. Wherein polyvinyl butyral and dibutyl phthalate mass ratio are 1:2, graphene and binding agent mass ratio are 3:1, be 25wt% to control graphene massfraction, ultrasonic power is 100W, The time is 1h;

[0044] (3) Load the graphene slurry into the extrusion device, use the syringe to squeeze the graphene slurry out of the n...

Embodiment 2

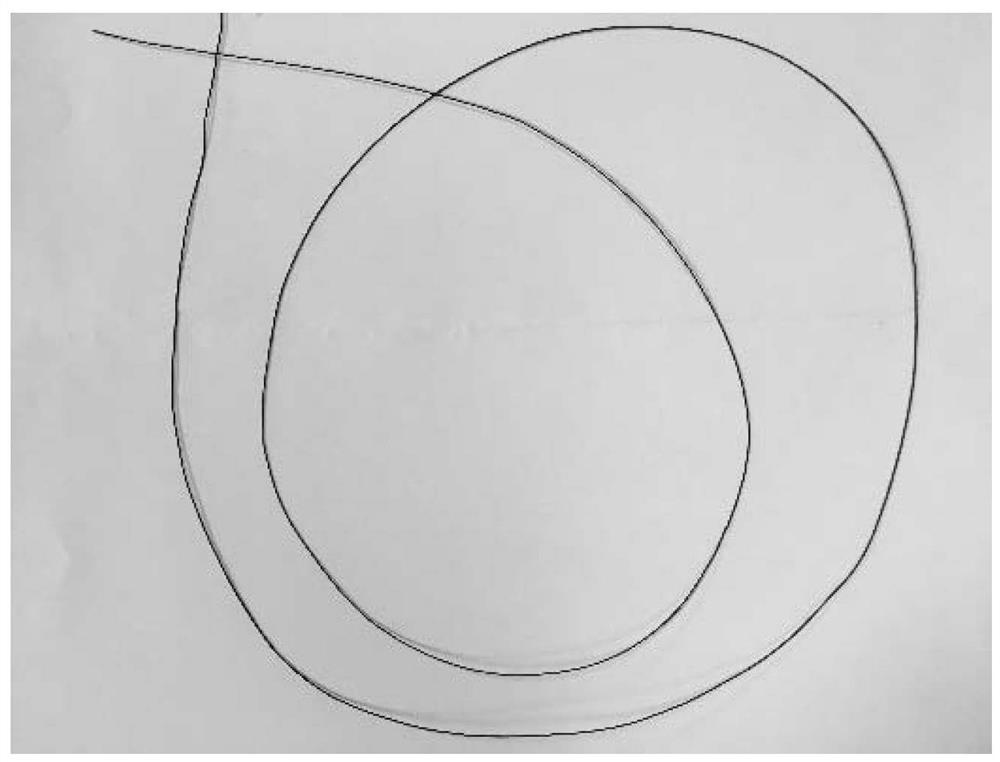

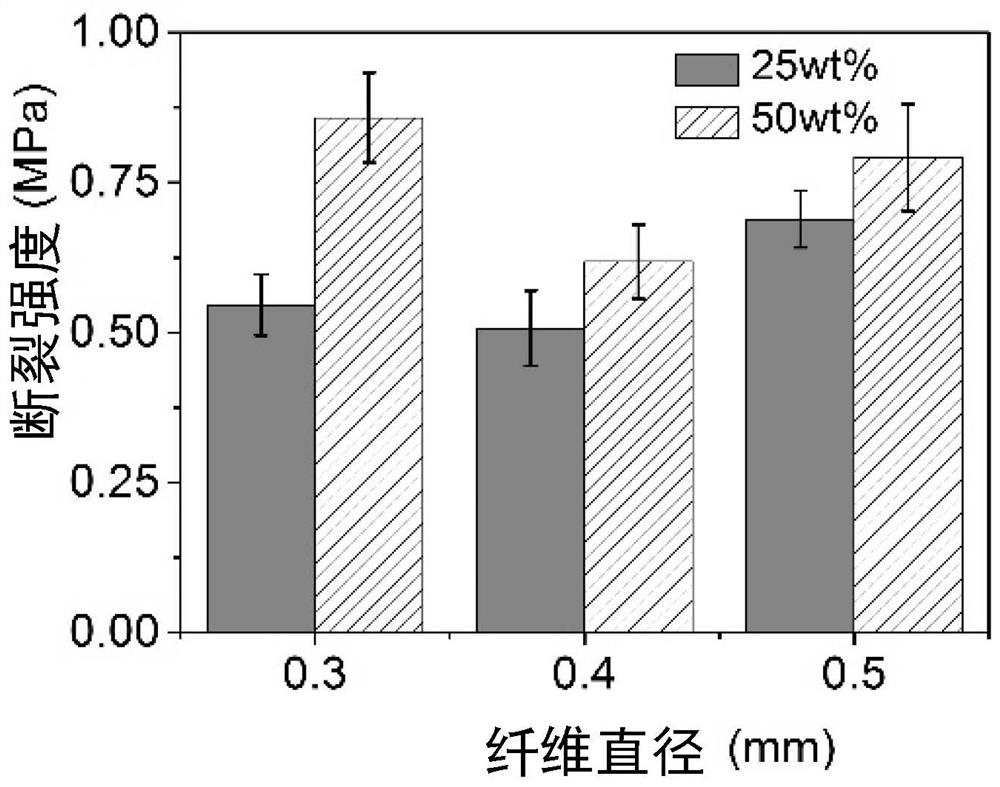

[0047] The difference between this embodiment and embodiment 1 is: in the step (3) of the preparation step, the air pressure of the syringe is controlled to be 0.35 MPa. An ultra-long graphene fiber (100cm in length) with a complete and clear structure, self-supporting, and controllable diameter was obtained, with a tensile strength of 0.5MPa. The test results are as follows image 3 As shown, the diameter is about 400 μm, and the scanning electron microscope (SEM) picture is as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com