Composite column composite beam frame with built-in tube high-strength concrete core column and its construction method

A technology of high-strength concrete and construction methods, which is applied in the direction of architecture and building construction, can solve the problems of difficult layout of prestressed tendons and large cross-sectional dimensions, and achieve the goals of shortening the construction period, improving axial compression performance, and reducing deformation and cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

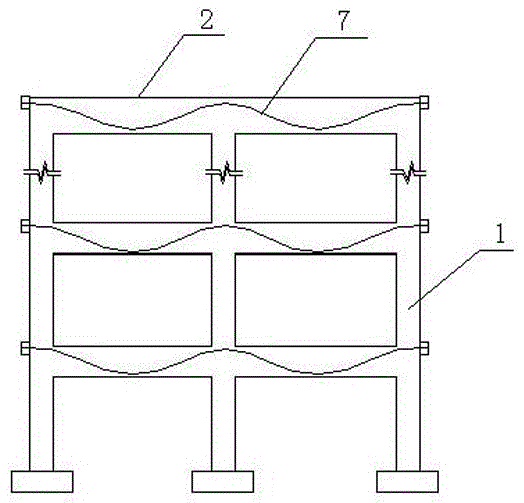

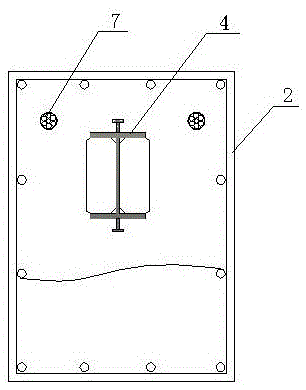

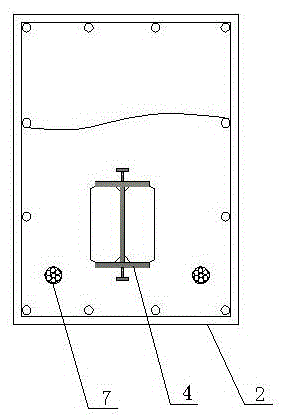

[0047] like figure 1 As shown, the composite column composite beam frame with built-in tube high-strength concrete core column has a built-in asymmetrical steel or plastic bone prestressed concrete composite beam 2, a reinforced concrete composite column 1 with a built-in core column, and the composite beam 2 is arranged horizontally Between the combined columns 1, the two are connected by nodes at the intersection. The core column 3 is placed in a reinforced concrete column. combine Figure 8 , Figure 15 As shown, the prestressed tendon 7 at the beam-column node passes through both sides of the core column 3, and is stretched and anchored at the end of the composite column. The H-shaped steel or plastic bone in the composite beam 2 is connected to the core column 3 through double-half snap rings 6 fixed connections, see Figure 9 . In this embodiment, the same type of concrete is used for the core column 3 and the reinforced concrete column on its outer side.

[0048] ...

Embodiment 2

[0061] This composite column composite beam frame with built-in tube high-strength concrete core column has a built-in asymmetrical steel or plastic bone prestressed concrete composite beam 2, a reinforced concrete composite column 1 with a built-in core column 3, and the composite beam 2 is horizontally arranged on the composite beam. Between the columns 1, the two are connected by nodes at the intersection; the core column 3 is a steel tube concrete column or FRP tube concrete column; the core column 3 is placed in a reinforced concrete column; the cross-section of the composite beam 2 is rectangular, and the steel frame 4 or The plastic bone is H-shaped, the steel frame 4 or plastic bone is provided with transverse stiffeners 5, the steel frame 4 or plastic bone is located at the lower part of the composite beam 2 at the mid-span, and the steel frame 4 or plastic bone at the support is located at the upper part of the composite beam 2 , the prestressed tendons 7 are set in t...

Embodiment 3

[0070]This composite column composite beam frame with built-in tube high-strength concrete core column has a built-in asymmetrical steel or plastic bone prestressed concrete composite beam 2, a reinforced concrete composite column 1 with a built-in core column 3, and the composite beam 2 is horizontally arranged on the composite beam. Between the columns 1, the two are connected by nodes at the intersection; the core column 3 is a steel tube concrete column or FRP tube concrete column; the core column 3 is placed in a reinforced concrete column; the cross-section of the composite beam 2 is rectangular, and the built-in steel frame 4 or the plastic bone is H-shaped, the steel frame 4 or the plastic bone is provided with transverse stiffeners 5, the steel frame 4 or plastic bone is located at the lower part of the composite beam 2 at the mid-span, and the steel frame 4 or plastic bone is located at the composite beam 2 at the support The prestressed tendons 7 are arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com