Middle and small power laser GMA electrical arc compound welding method appending with mechanical force

A hybrid welding, -GMA technology, applied in the field of laser-GMA arc hybrid welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

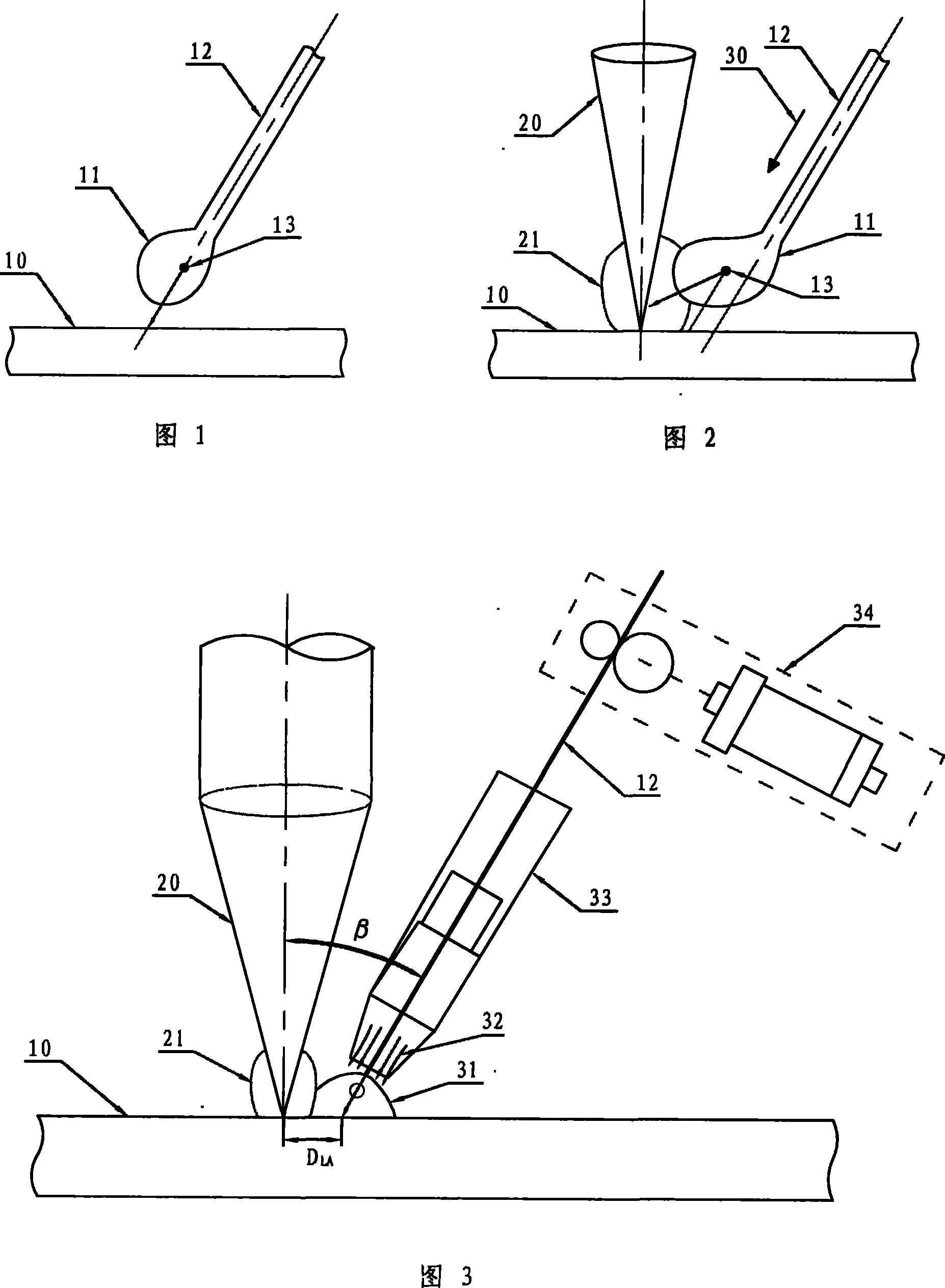

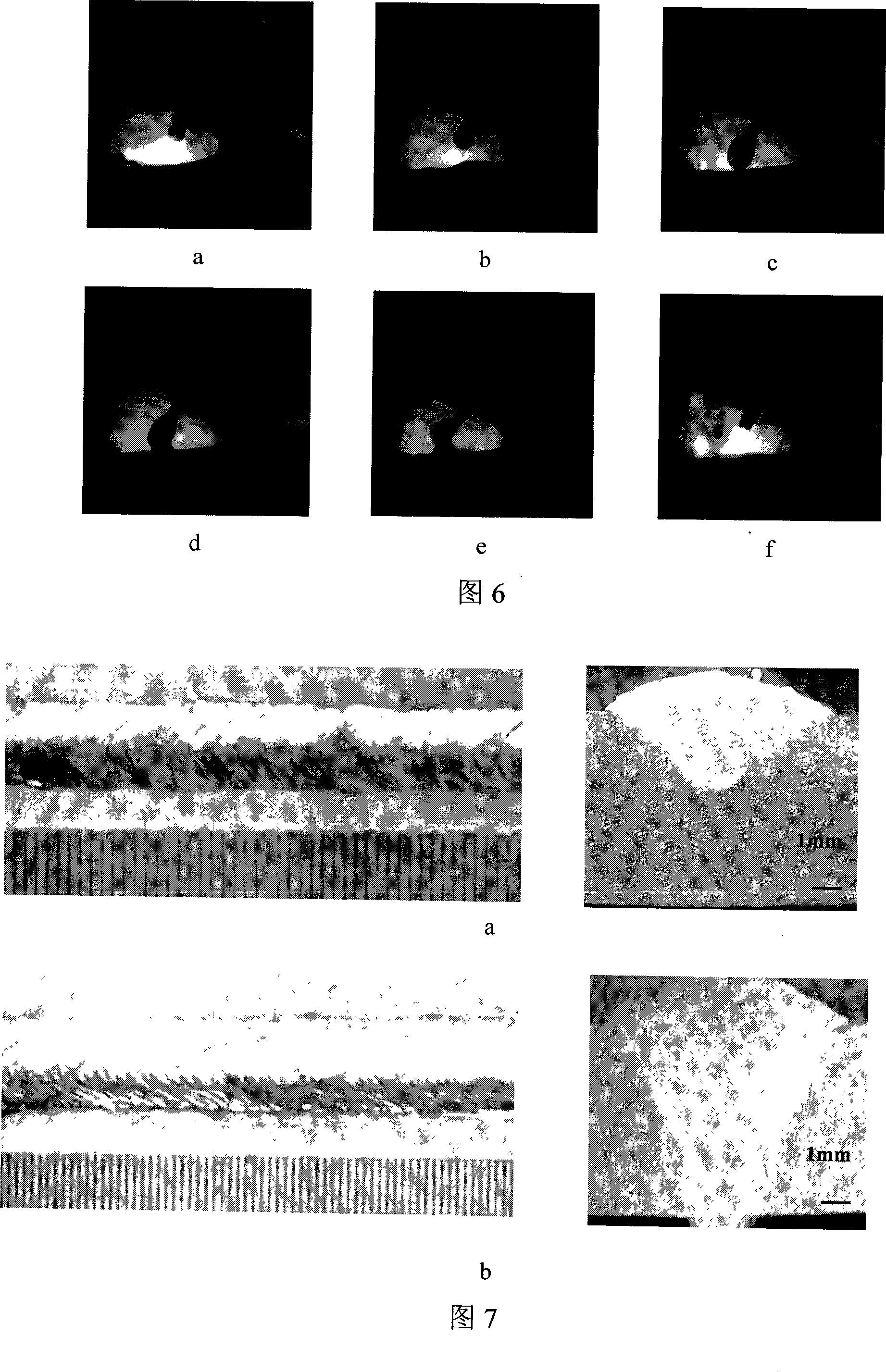

[0013] Specific embodiment 1. The medium and low power laser-GMA arc hybrid welding method with additional mechanical force of this embodiment is to apply additional mechanical force to the droplet along the axis of the GMA wire in the existing medium and low power laser-GMA arc hybrid welding process. Promote the droplet transition in advance.

[0014] The additional mechanical force of this embodiment can be applied when the droplet of the hybrid welding grows to a certain extent, that is, before the droplet of the hybrid welding shifts to the direction of the laser beam. In this embodiment, it can be between 0.7T and 0.95T. Mechanical force is applied between them to achieve the purpose of prompting the droplet to achieve transition in advance. The period T is the same as the droplet transfer period of the existing single GMA arc welding under the same conditions, and it is determined according to the arc current during welding and the material and diameter of the welding wire...

specific Embodiment approach 2

[0016] The second embodiment is that the difference between this embodiment and the medium and low power laser-GMA arc hybrid welding method with additional mechanical force described in the first embodiment is that the additional mechanical force is generated by increasing the shielding gas flow of the GMA arc welding gun of.

[0017] In this embodiment, the shielding gas flow rate of the GMA arc welding gun is used to apply mechanical force to the droplets. During normal welding, the shielding gas flow rate of the GMA arc welding gun is 10-25 liters / minute commonly used in the prior art. When it grows up to a certain extent, that is, before the composite welding droplet shifts to the direction of the laser beam, that is, between 0.75T and 0.85T of the droplet transition, the shielding gas flow rate is increased to 40-100 liters instantly / Min, so that the droplet transitions in advance under the action of the protective gas.

[0018] This embodiment can use CO 2 Or YAG laser and...

specific Embodiment approach 3

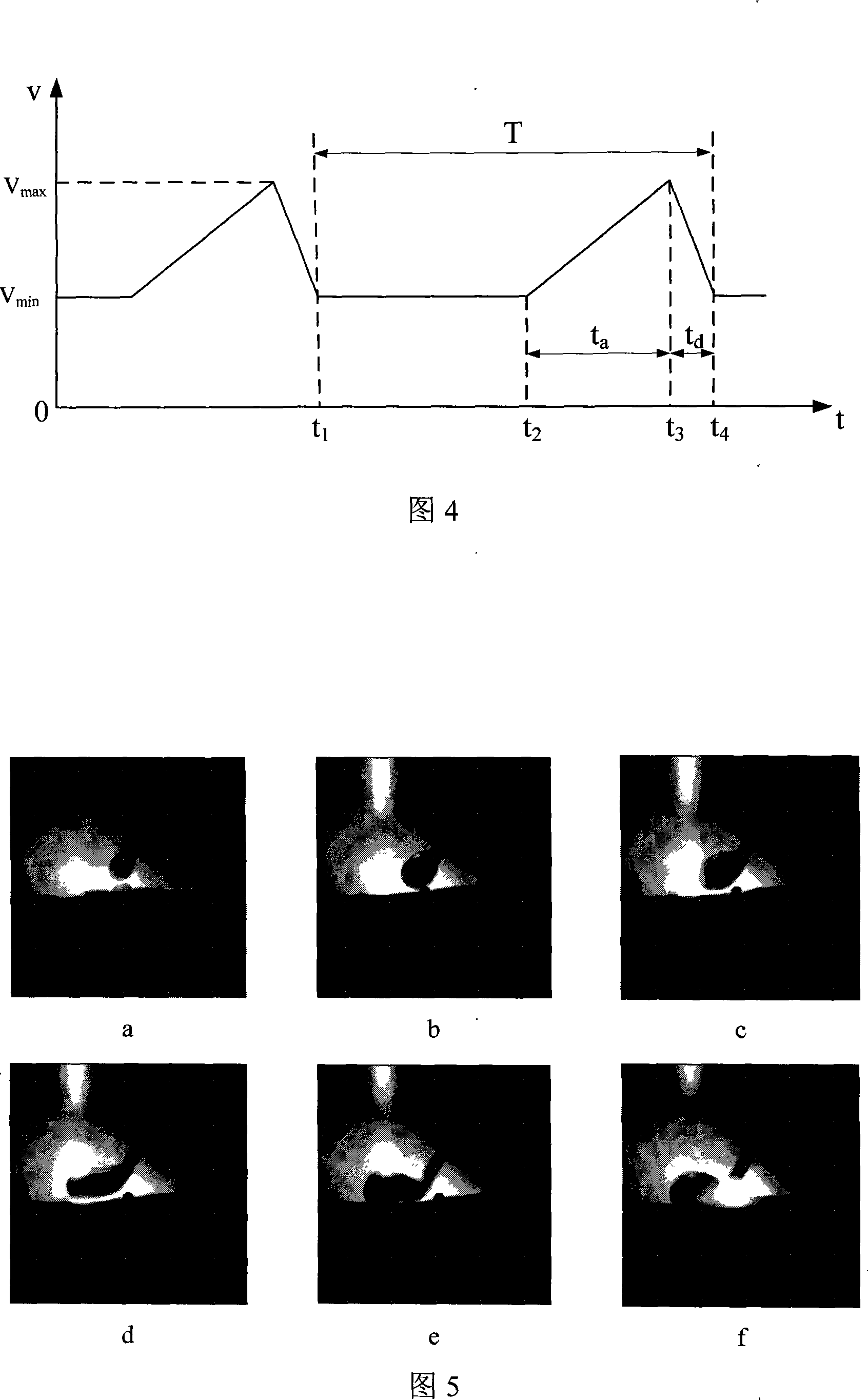

[0024] Specific embodiment three. The difference between this embodiment and the medium and low power laser-GMA arc hybrid welding method with additional mechanical force described in the first embodiment is that the additional mechanical force is used to control the wire feeding speed of the GMA arc welding gun in the cycle It is realized by a pulsating change in T, the starting time t of the pulsating change 2 It is between 0.7T and 0.8T of the droplet transition.

[0025] The pulsation change described in this embodiment means that the wire feeding speed changes in a sawtooth waveform, a triangular waveform or a sine waveform within the period T with time, wherein the acceleration time period of the wire feeding is t a 0.15T~0.25T, the deceleration time period of wire feeding t d It is 0.05T~0.15T.

[0026] In this embodiment, pulsating wire feeding is used to add mechanical force. In the laser-GMA arc hybrid welding process, pulse wire feeding is used to apply a certain amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com