Yarn sizing device

A yarn and paddle wheel technology, which is applied to the processing of textile materials, equipment configuration, textiles and papermaking, textile processing machine accessories, etc., can solve the problems of clumped pulp that cannot be soaked and yarn sizing effect becomes poor, and achieves improved Sizing effect, waste reduction, wettability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

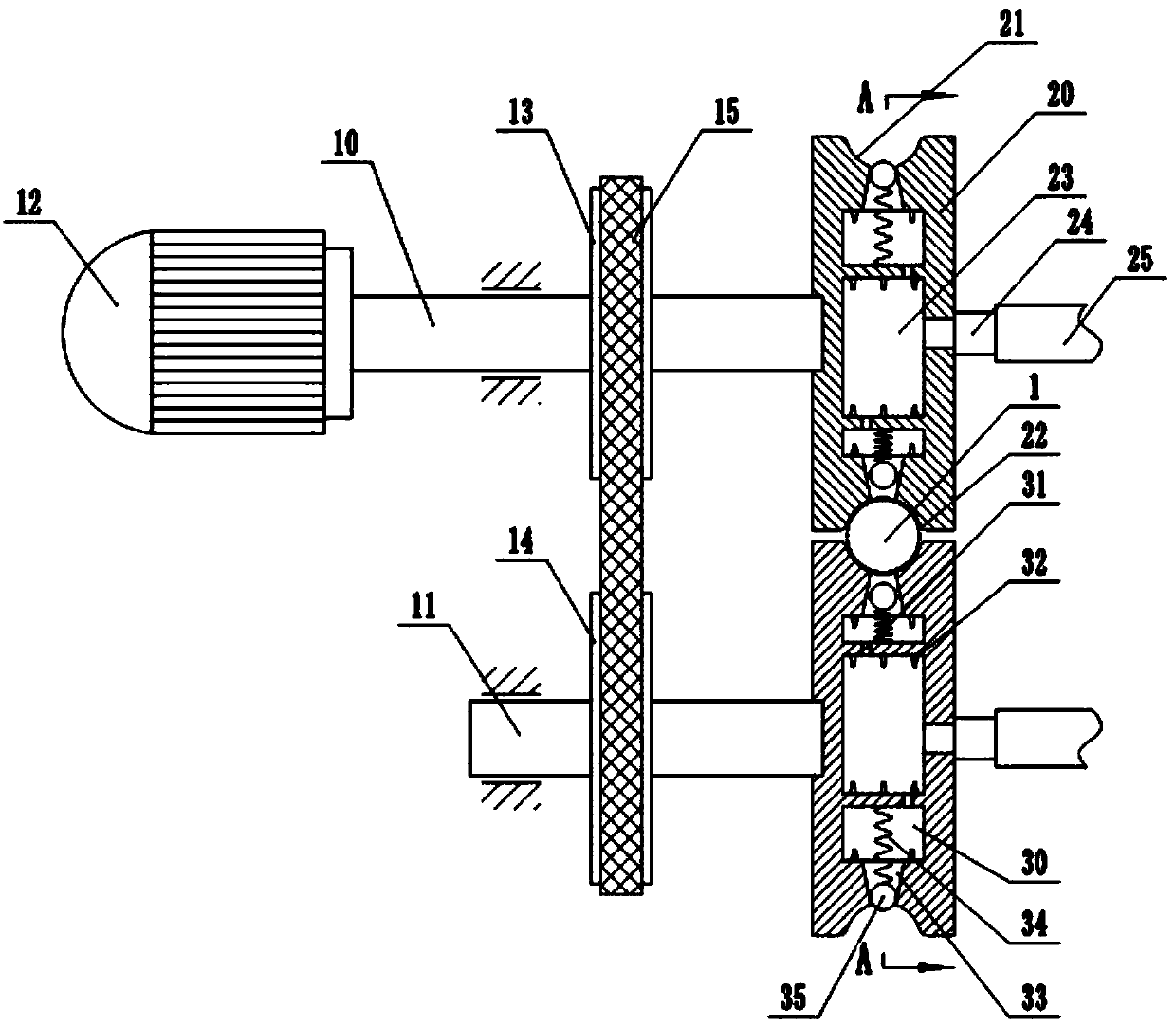

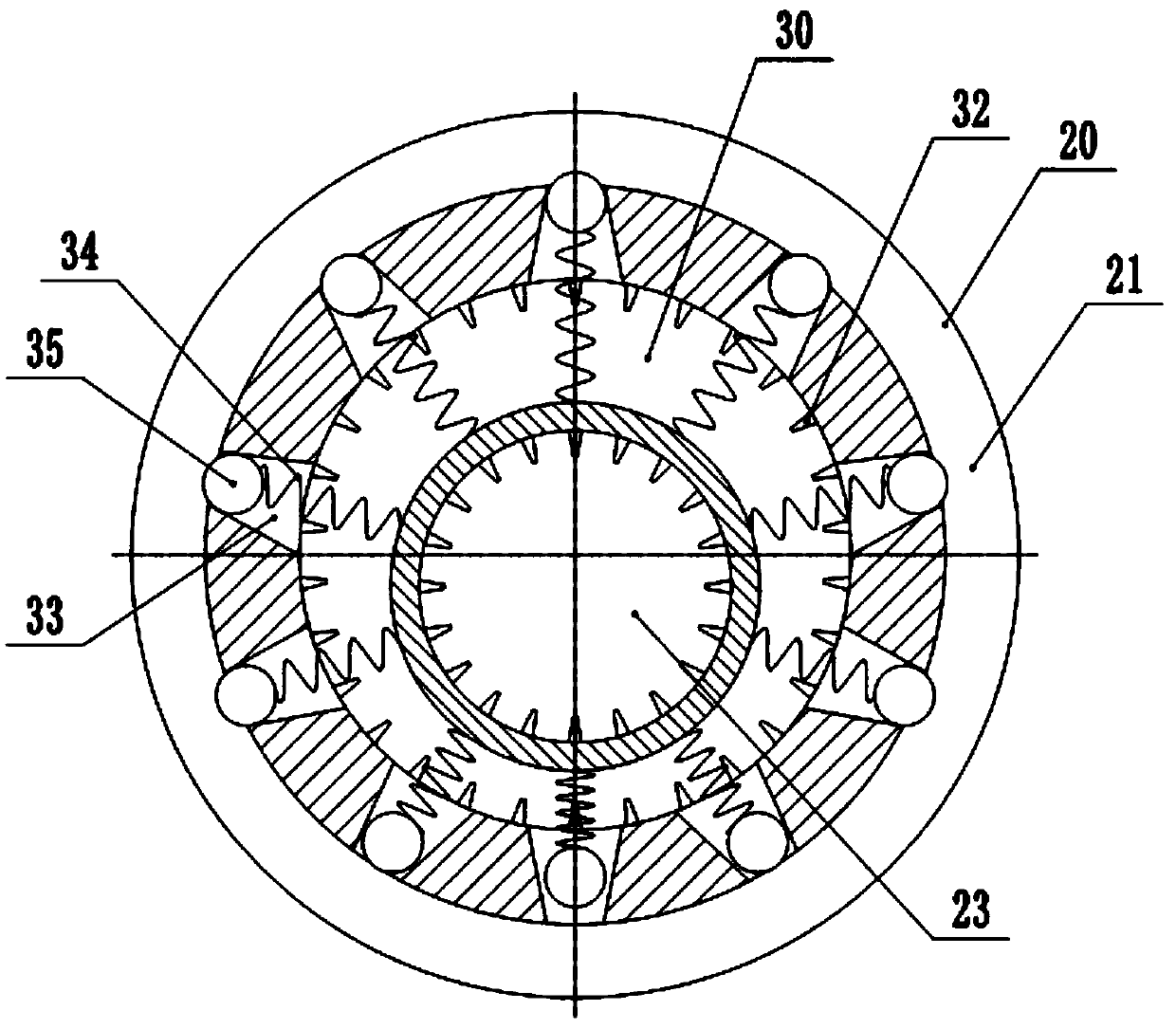

[0027] The reference numerals in the drawings of the description include: yarn 1, first wheel shaft 10, second wheel shaft 11, motor 12, driving pulley 13, driven pulley 14, belt 15, sizing wheel 20, annular groove 21, sizing Groove 22, transfer chamber 23, rotary joint 24, feed pipe 25, annular mixing chamber 30, diversion channel 31, protruding teeth 32, slurry outlet 33, spring 34, ball 35.

[0028] The embodiment is basically as attached figure 1 and figure 2 Shown:

[0029] The yarn sizing device includes a frame on which a first wheel shaft 10 and a second wheel shaft 11 are connected horizontally from top to bottom, the first wheel shaft 10 is connected with a motor 12, the first wheel shaft 10 and the second wheel shaft 11 A belt transmission mechanism is connected therebetween, and this belt transmission mechanism comprises a driving pulley 13 fixed on the first wheel sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com