Soft sealing groove gate valve

A soft seal and groove technology, applied to the valve details, valve device, valve housing structure, etc., can solve the problems of high cost of installation, disassembly and maintenance, high error rate of operation, and complicated operation process, so as to save manpower, manufacture Simple, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

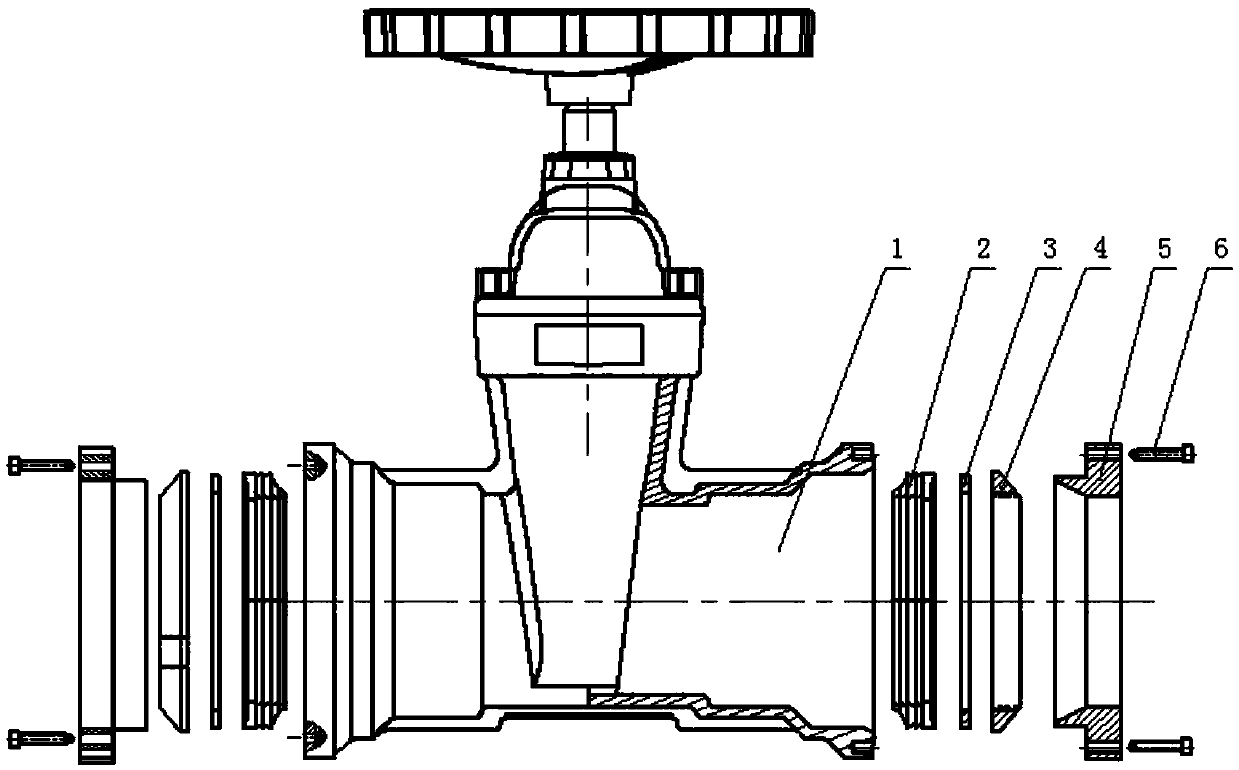

[0021] A soft-sealing grooved gate valve includes a valve body 1 and a pressure flange 5, the left and right ends of the valve body are coaxially installed with pressure flanges, and the pressure flange is connected with the valve body through screws 6.

[0022] The innovation point of the present invention is:

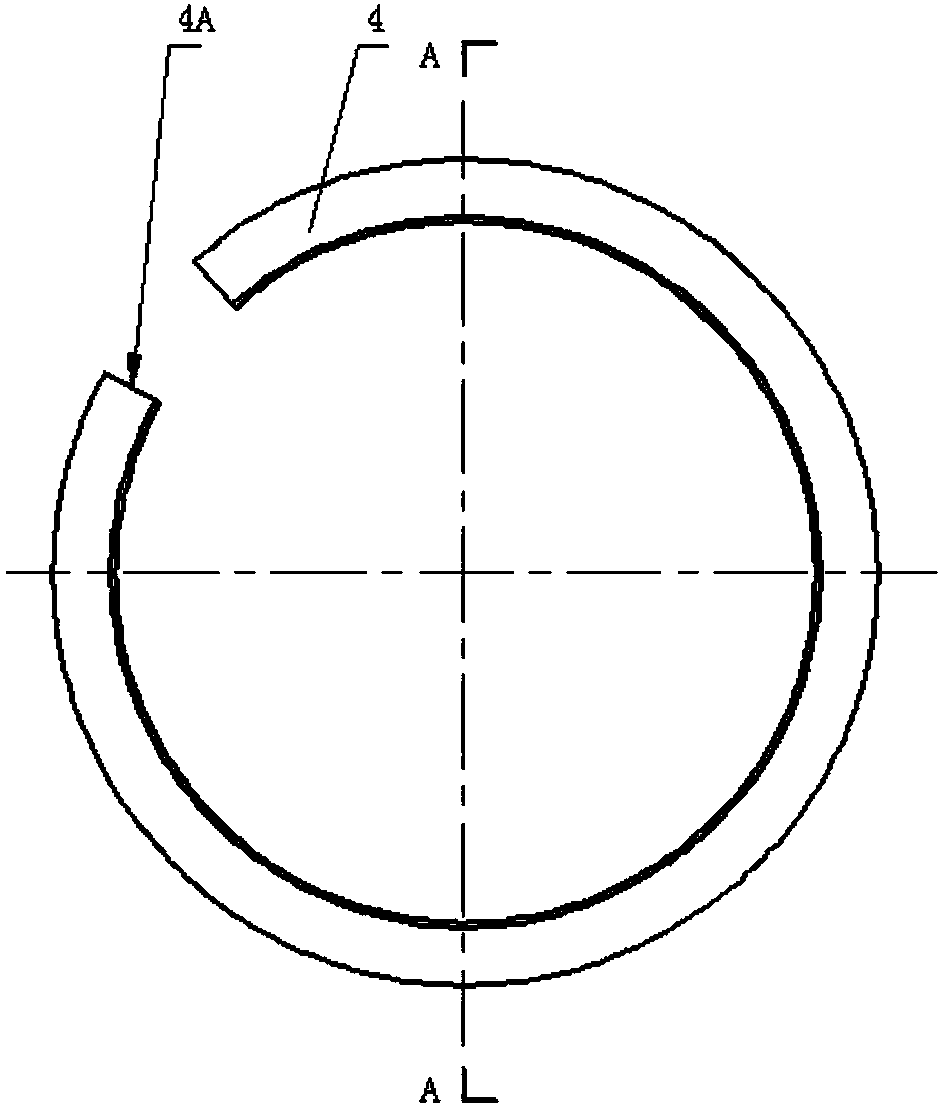

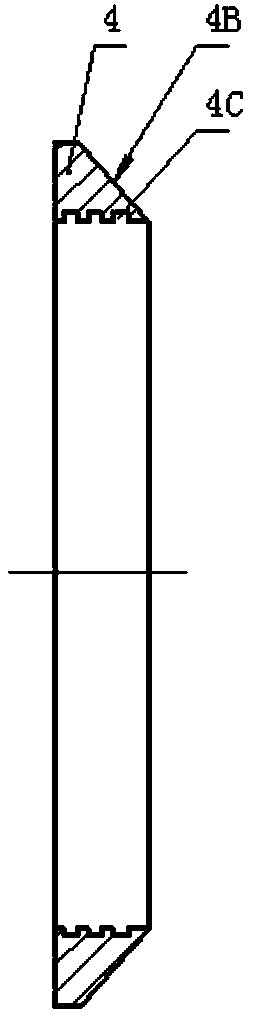

[0023] 1. A sealing ring 2, a pressure ring 3 and a C-shaped hoop ring 4 are installed in the valve body on the inner side of the pressure flange in sequence from the inside to the outside. The structure of the C-shaped hoop ring is as figure 2 , image 3 As shown, an opening 4A is formed on one side of the C-shaped hoop ring, and the surface of the C-shaped hoop ring in contact with the pressure flange is a tapered surface 4B. The C-shaped clamping ring and the pressure flange are connected by a tapered surface, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap