Fabric drying control method and device with multiple steam drying cylinders

A technology of steam drying cylinder and control method, which is applied in the direction of heating device, drying, drying machine, etc., which can solve the problems of not being able to meet different temperature deviations and deviation change rates, increasing the self-weight of steam drying cylinders, and small steam pressure, etc., to achieve Good uniform expansion characteristics, reduced steam consumption, accurate and stable moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

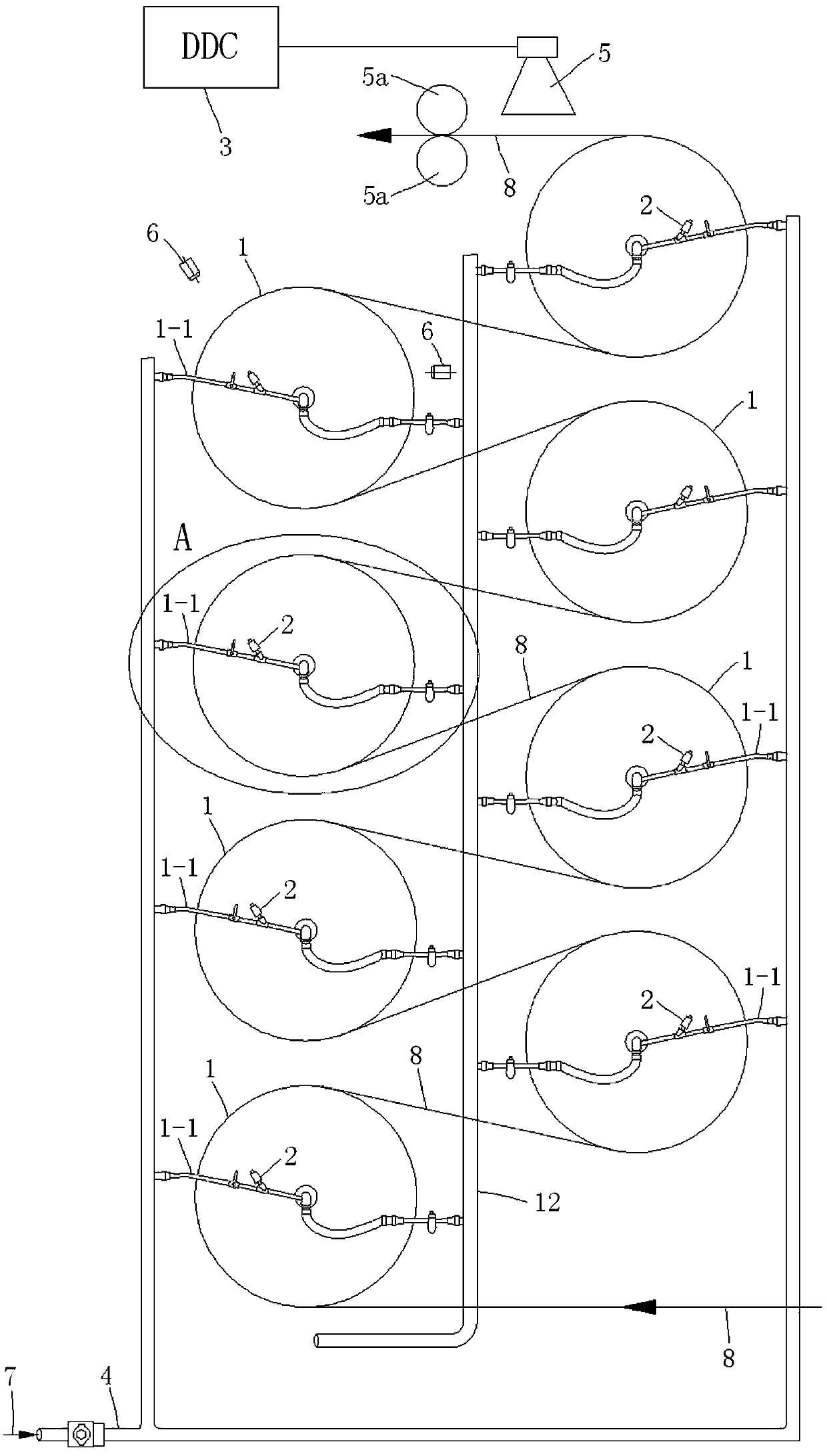

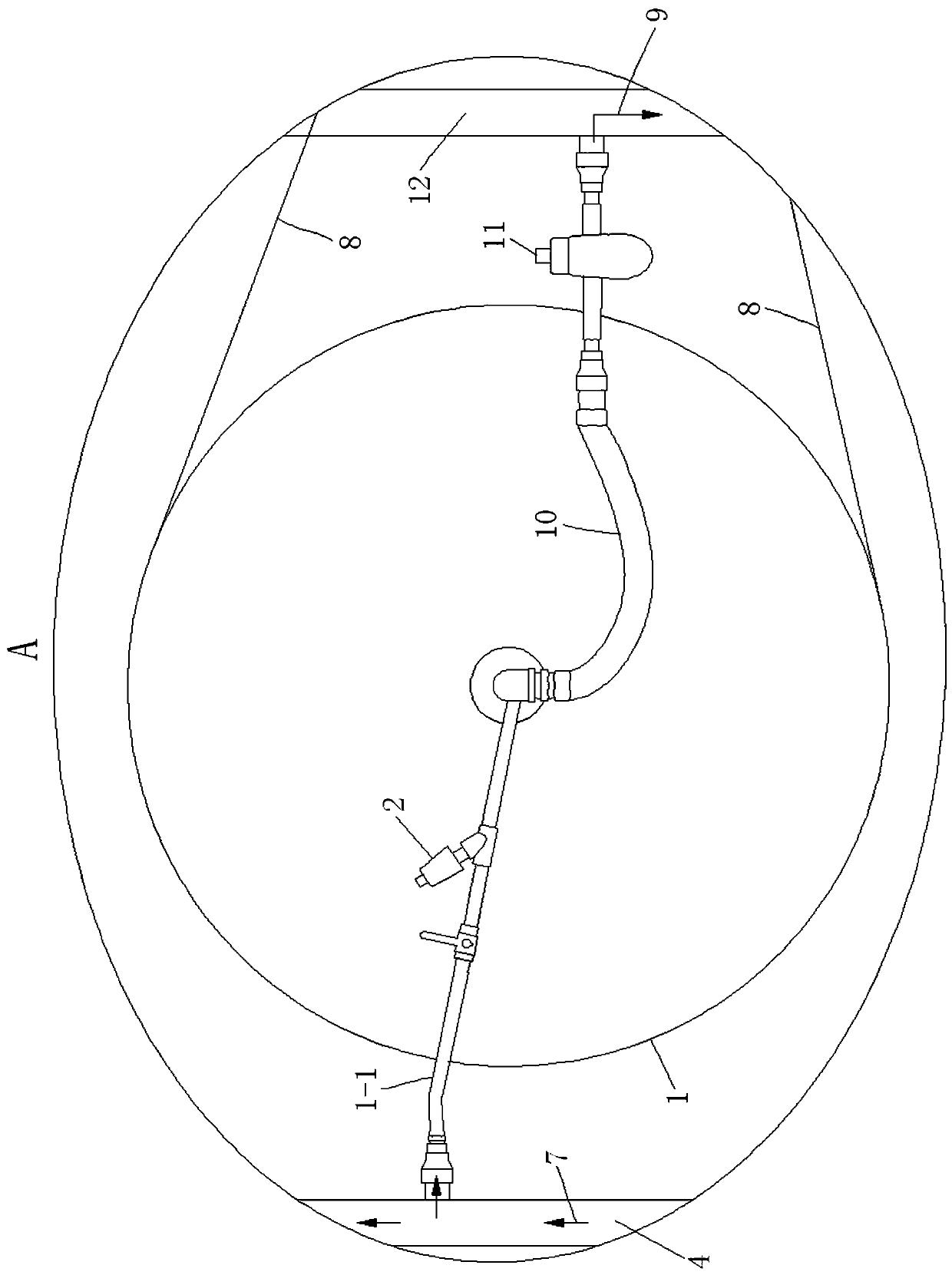

[0042] As a preferred embodiment of the present invention, the moisture content detection mechanism of the fabric is a moisture sensor 5, and the moisture sensor 5 is connected to the electric controller 3. During operation, the moisture sensor 5 detects the moisture content of the fabric , and transmit the detection data to the electrical controller 3 . Described moisture sensor 5 can be non-contact radio frequency wave moisture sensor, fabric 8 is carried out non-destructive detection, is converted into the moisture content rate of fabric by electric controller 3; Described moisture sensor 5 also can be contact type moisture sensor, and fabric 8 is in Pass between two mutually insulated cloth guide rollers 5a, detect the resistance change between the two cloth guide rollers 5a and map it as the moisture content of the fabric, and convert it into the moisture content of the fabric by the electric controller 3.

[0043] As a preferred embodiment of the present invention, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com