Detecting device and method for cleanliness of oil liquid and hydraulic machine

A detection device and cleanliness technology, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve the problems of expensive instruments and high cost of detection devices, so as to improve accuracy and avoid oil pollution , to ensure the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

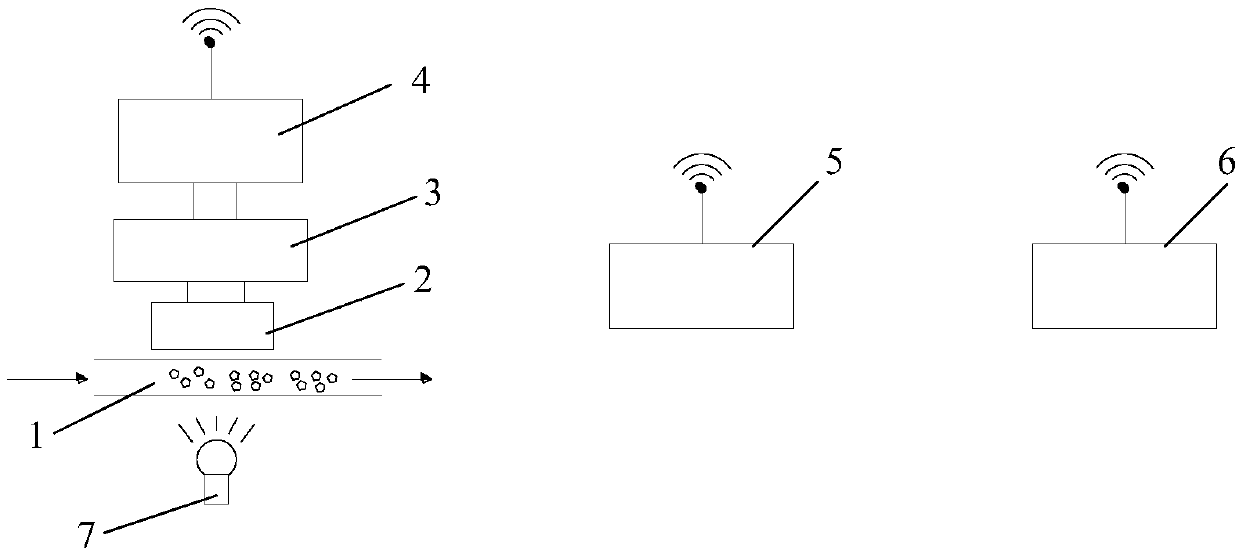

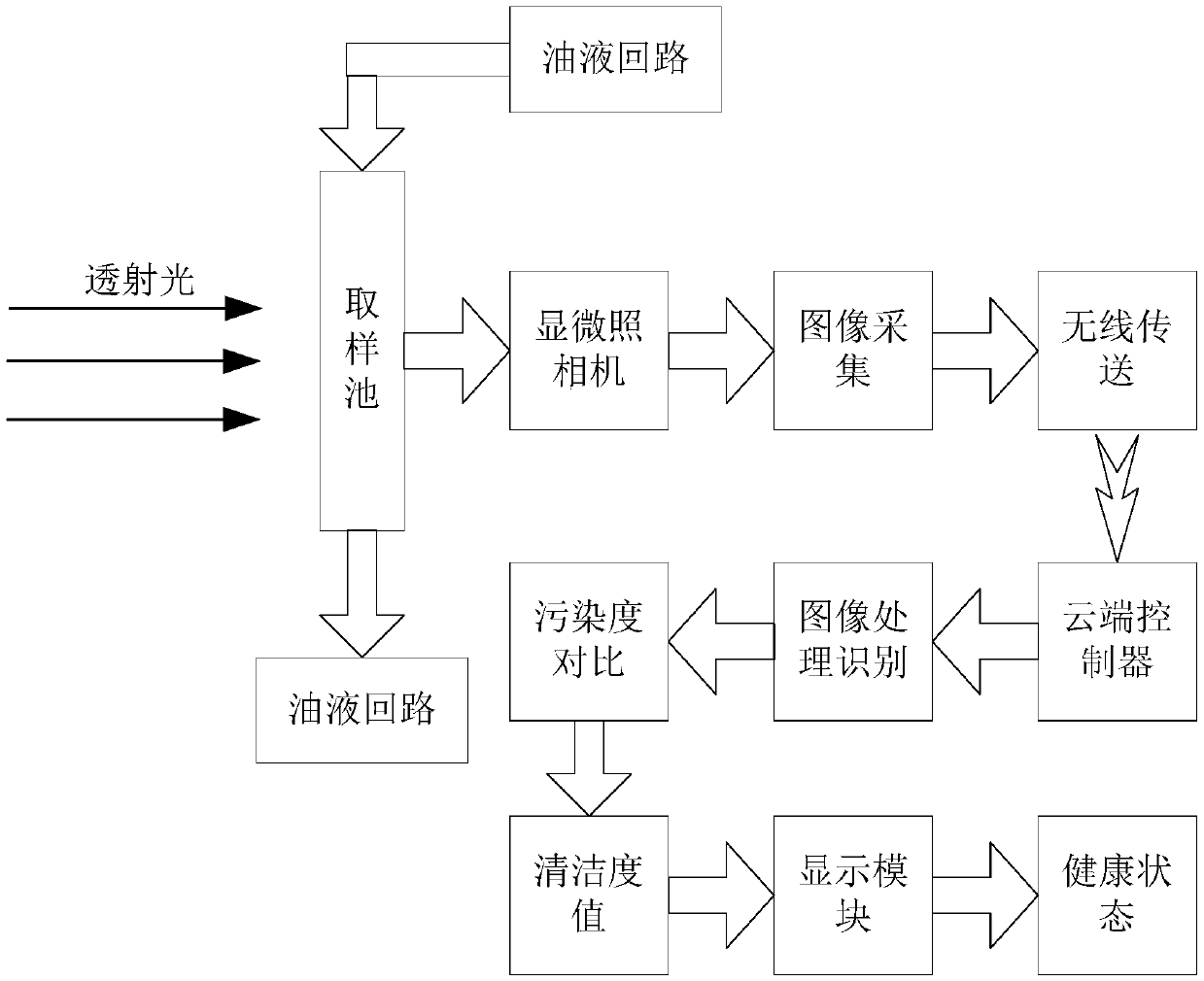

[0048] Such as figure 1 and figure 2 As shown, the oil cleanliness detection device includes: a sampling pool 1, a microscopic image acquisition module and a processing module, the inlet and outlet of the sampling pool 1 are respectively connected to the oil circuit of the hydraulic machine, and the microscopic image acquisition module includes a microscopic camera 2 , the image acquisition card 3 and the local controller 4, the microscopic camera 2 is used to take pictures and samples the oil in the sampling pool 1, to obtain microscopic images, the image acquisition card 3 is connected with the microscopic camera 2 and the local controller 4, The processing module includes a cloud controller 5 and a cloud storage. The local controller 4 and the cloud controller 5 are respectively connected with a wireless transmission module to realize signal transmission between the local controller 4 and the cloud controller 5. The cloud storage is used to store oil For the pattern datab...

Embodiment 2

[0059] The oil cleanliness detection device includes: a sampling pool, a microscopic image acquisition module and a processing module. The inlet and outlet of the sampling pool are respectively connected to the oil circuit of the hydraulic machine. The micro camera is used to take pictures of the oil in the sampling pool to obtain microscopic images. The processing module includes a local controller and a local memory. The image acquisition card is connected with the microscopic camera and the local controller. The local memory is used to store the oil. In the pattern database under different pollution degrees, the local controller is used to compare and analyze the microscopic image with the patterns in the pattern database to obtain the cleanliness of the oil.

[0060] In this scheme, the pattern database is stored in the local memory, and the local controller compares the microscopic image with the pattern in the local memory to obtain the cleanliness of the oil. This scheme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com