Step-down voltage dividing bias circuit based on in-well high-voltage high-precision polycrystalline resistor

A technology of polysilicon resistors and bias circuits, applied in electrical components, physical parameter compensation/prevention, code conversion, etc., can solve the problem of difficulty in maintaining the thickness of silicided and non-silicided regions, the influence of polysilicon resistance accuracy, and the reduction of gate height, etc. problem, to achieve the effect of simplifying the ultra-high voltage step-down voltage divider bias circuit, improving integration and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

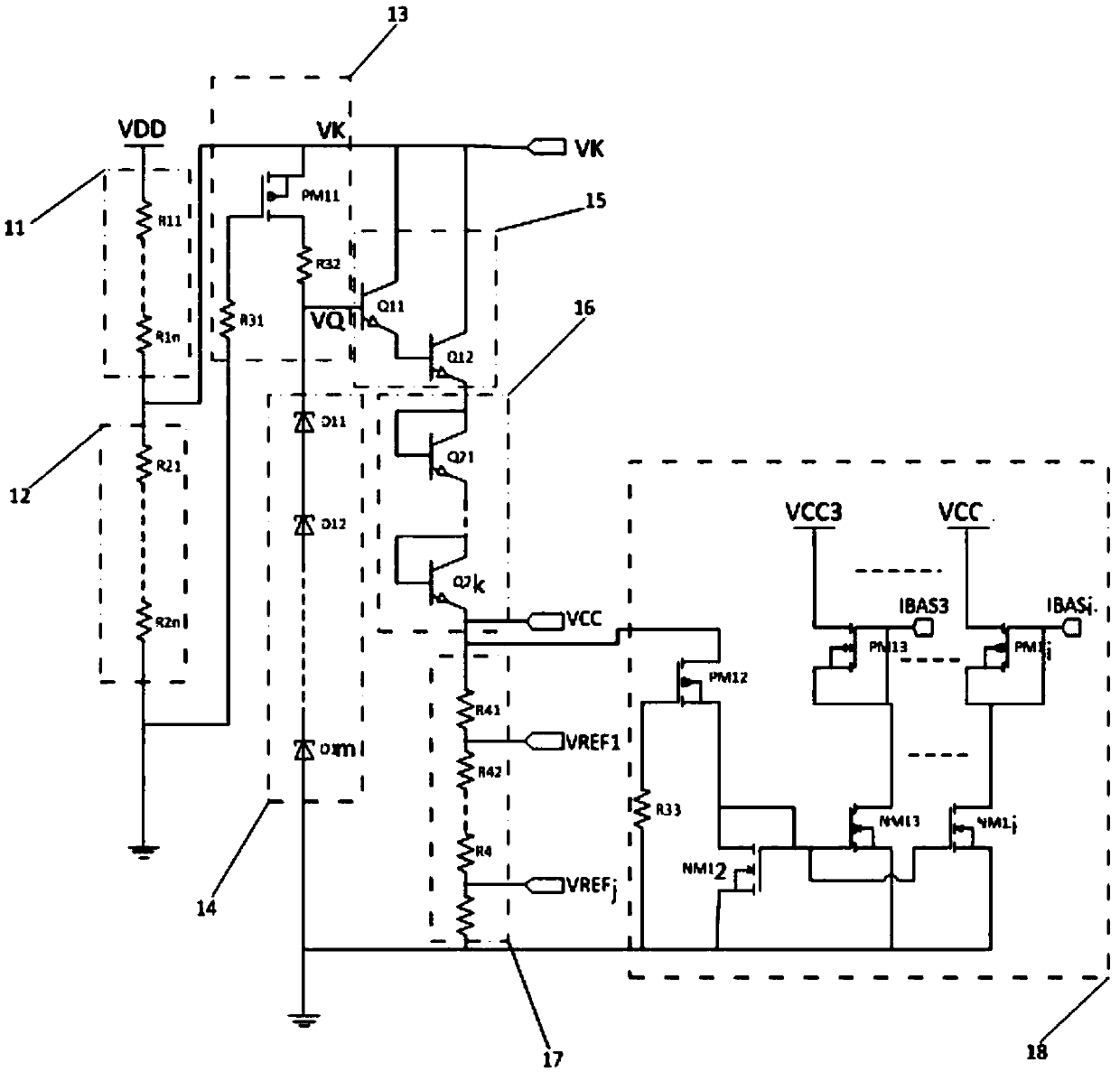

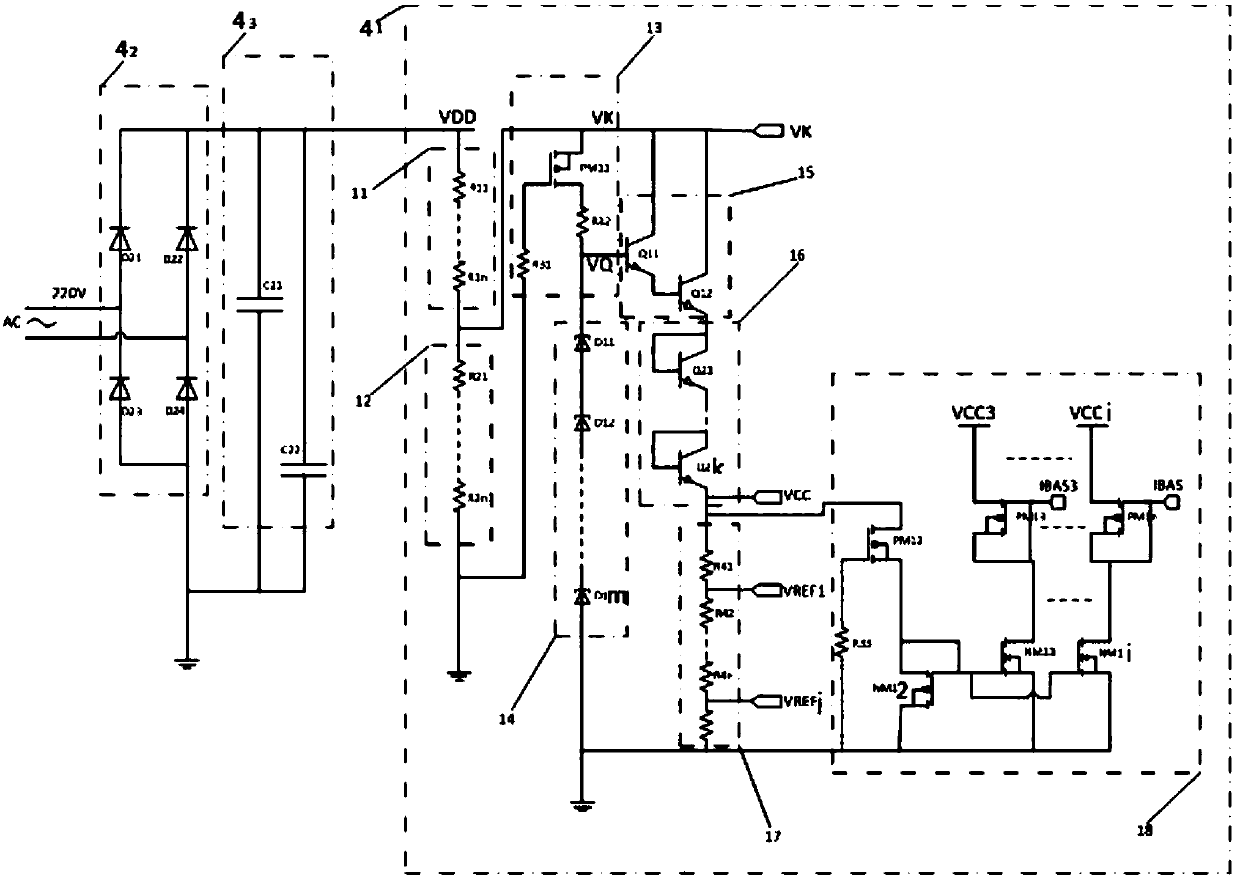

[0022] figure 1 Shown is a voltage-dividing voltage-dividing bias circuit based on high-voltage and high-precision polycrystalline resistors in the well provided by the present invention, which includes 2 high-voltage-resistant and high-precision polycrystalline resistor voltage-dividing networks 11 and 12, voltage self-biasing Set circuit parts 13 and 14, bipolar compound tube 15, series voltage divider 16, series resistance voltage divider circuit 17 and current bias circuit part 18. figure 1 The specific working principle of the circuit shown is as follows:

[0023] 11 can be composed of multiple polycrystalline resistors with high withstand voltage and high precision in series, and 12 can be composed of multiple polycrystalline re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com